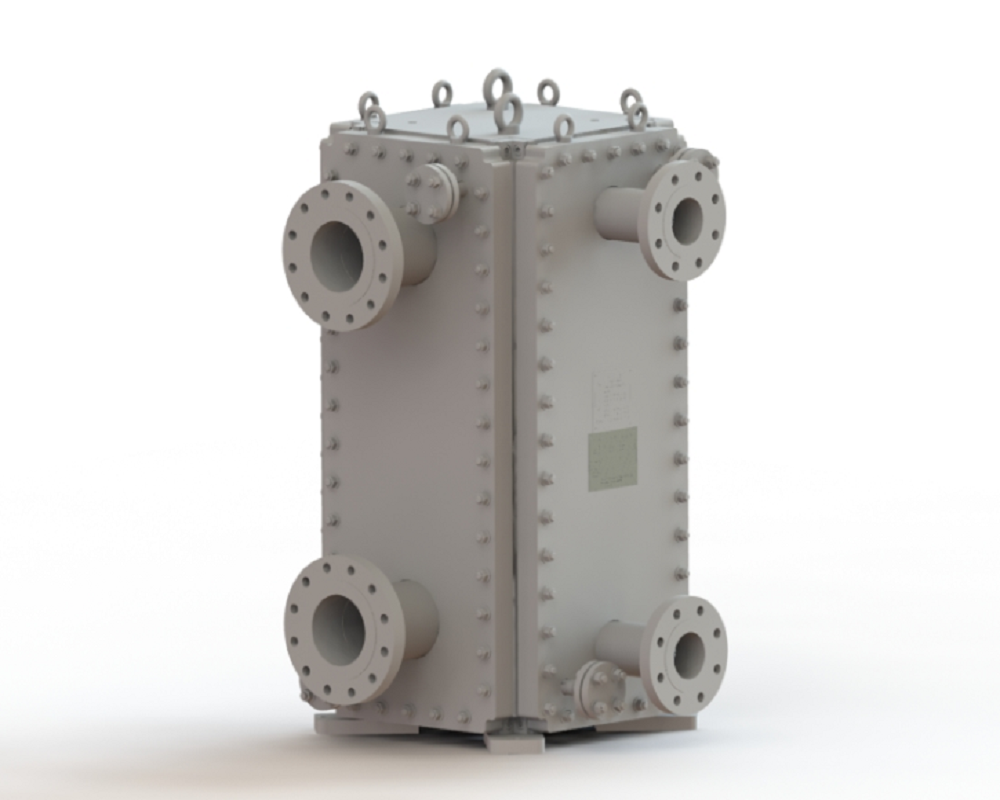

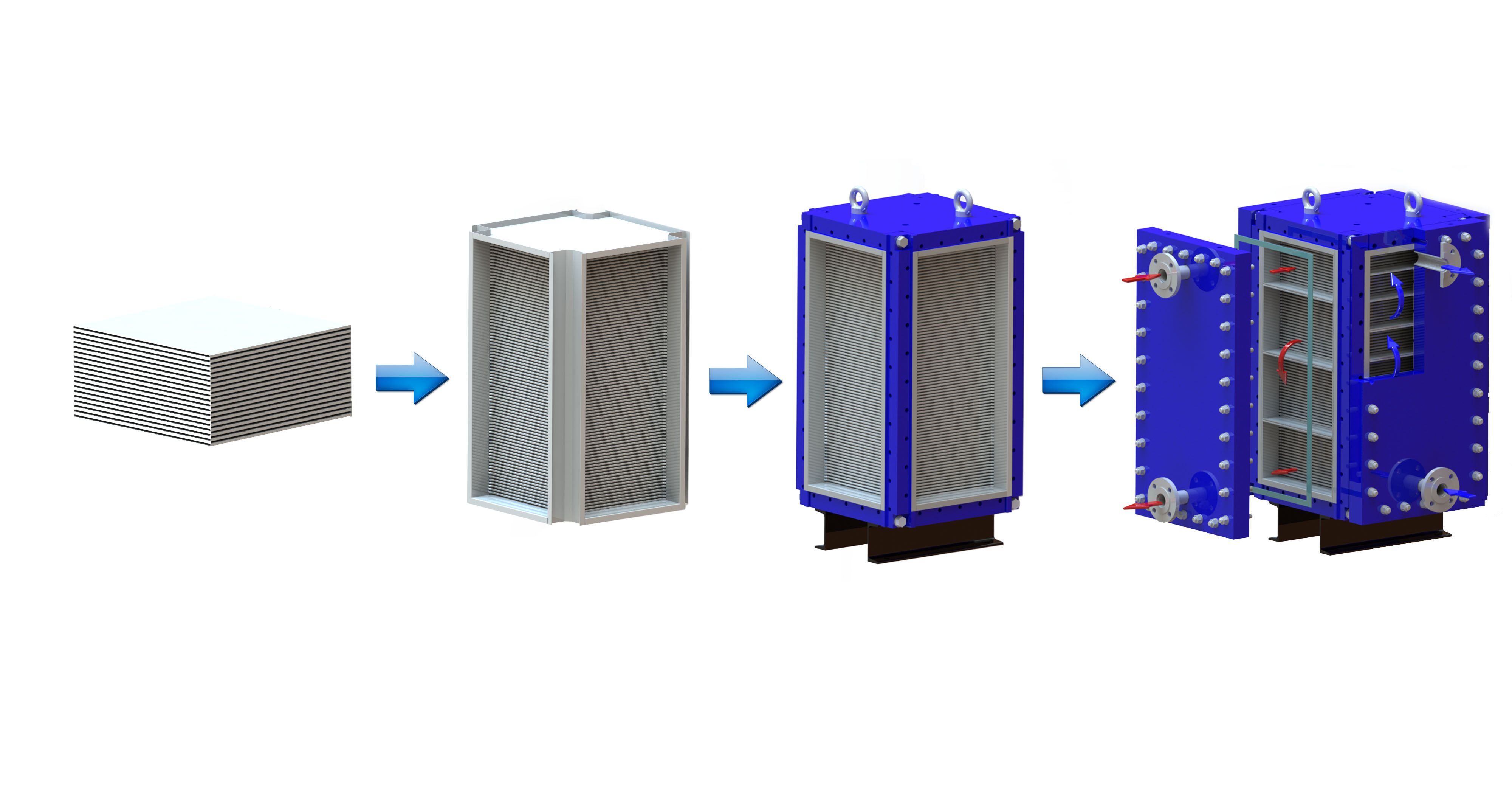

Bloc welded plate heat exchanger for Petrochemical industry

How it works

The cold and hot media flow alternately in welded channels between the plates.

Each medium flows in a cross-flow arrangement within each pass. For multi-pass unit, the media flow in countercurrent.

The flexible flow configuration makes both sides keeping the best thermal efficiency. And the flow configuration can be rearranged to fit the change of the flow rate or temperature in the new duty.

MAIN FEATURES

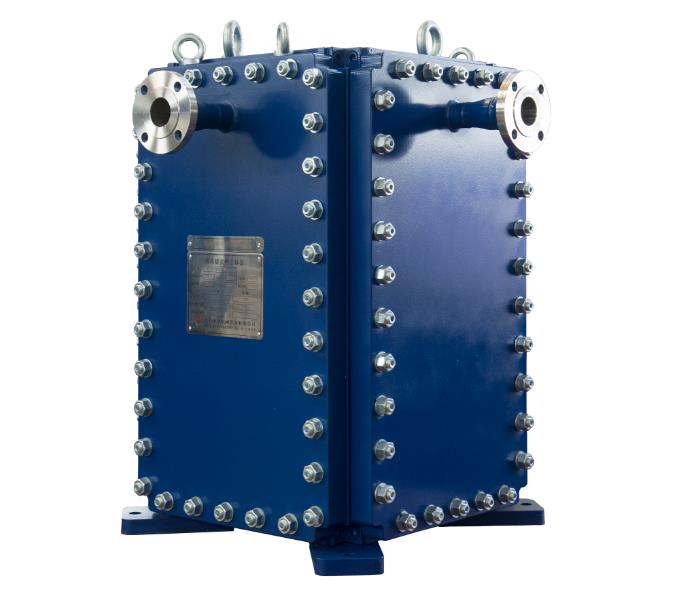

☆ Plate pack is fully welded without gasket;

☆The frame can be disassembled for repair and cleaning;

☆ Compact structure and small footprint;

☆ High heat transfer efficient;

☆ The butt welding of plates avoid risk of crevice corrosion;

☆ Short flow path fit low-pressure condensing duty and allow very low pressure drop;

☆ A variety of flow form meets all kinds of complex heat transfer process.

APPLICATIONS

☆Refinery

● Pre-heating of crude oil

● Condensation of gasoline, kerosene, diesel, etc

☆Natural gas

● Gas sweetening, decarburization—lean/rich solvent service

● Gas dehydration—heat recovery in TEG systems

☆Refined oil

● Crude oil sweetening—edible oil heat exchanger

☆Coke over plants

● Ammonia liquor scrubber cooling

● Benzoilzed oil heating, cooling