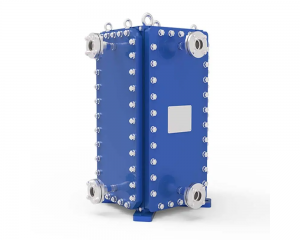

HT-Bloc heat exchanger with wide gap channel

How it works

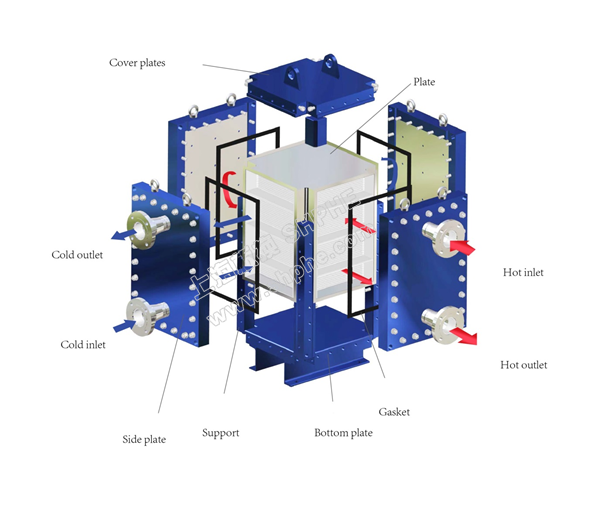

☆ HT-Bloc is made up of plate pack and frame. The plate pack is certain number of plates weldedtogether to form channels, then it is installed into a frame, which is formed by four corner.

☆ The plate pack is fully welded without gasket, girders, top and bottom plates and four side panels. The frame is bolted connected and can be easily disassembled for service and cleaning.

Features

☆ Small footprint

☆ Compact structure

☆ high thermal efficient

☆ The unique design of π angle prevent "dead zone "

☆ The frame can be disassembled for repair and cleaning

☆ The butt welding of plates avoid risk of crevice corrosion

☆ A variety of flow form meets all kinds of complex heat transfer process

☆ The flexible flow configuration can ensure consistent high thermal efficiency

☆ Three different plate patterns:

● corrugated,studded,dimpled pattern

HT-Bloc exchanger keeps the advantage of conventional plate & frame heat exchanger, such as high heat transfer efficiency, compact size, easy to cleaning and repair, moreover, it can be used at process with high pressure and high temperature, such as oil refinery, chemical industry, power, pharmaceutical, steel industry, etc.