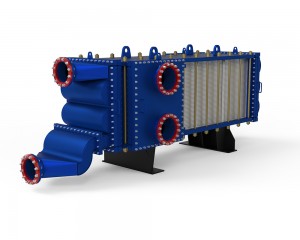

I-Wide Gap Welded Plate Heat Exchanger yefektri yokuhluza i-Alumina

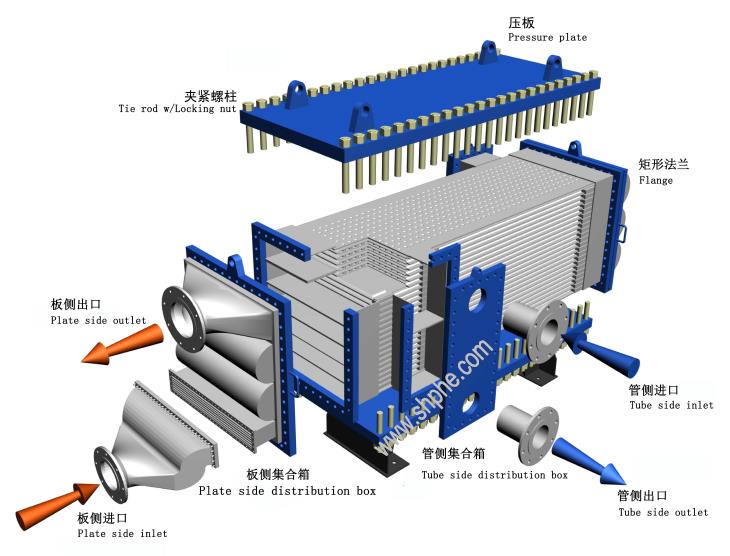

Isebenza kanjani?

I-plate heat exchanger ingasetshenziswa ikakhulukazi ekwelapheni ukushisa njengokushisa nokupholisa kwe-viscous medium noma i-medium equkethe izinhlayiya eziqinile kanye ne-fiber suspensions ezimbonini zikashukela, ekwenziweni kwephepha, ezinsimbini, e-ethanol nasezimbonini zamakhemikhali.

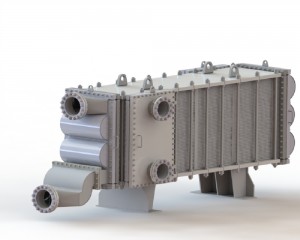

Umklamo okhethekile wepuleti lokushintshanisa ukushisa uqinisekisa ukusebenza kahle kokudlulisa ukushisa kanye nokulahlekelwa yingcindezi kunezinye izinhlobo zemishini yokushintshanisa ukushisa esesimweni esifanayo. Ukugeleza okubushelelezi koketshezi emseleni obanzi wegebe nakho kuyaqinisekiswa. Kufeza inhloso yokungabi "nendawo efile" kanye nokungabikho kokufakwa noma ukuvaleka kwezinhlayiya eziqinile noma ukumiswa.

Isiteshi esisohlangothini olulodwa sakhiwe phakathi kwepuleti eliyisicaba kanye nepuleti eliyisicaba elihlanganiswe ndawonye nge-stud. Isiteshi esisohlangothini olulodwa sakhiwe phakathi kwamapuleti ayisicaba anesikhala esikhulu, futhi asikho indawo yokuxhumana. Zombili iziteshi zifanelekela i-medium ephezulu noma i-medium equkethe izinhlayiya eziqinile kanye ne-fiber.

Isicelo

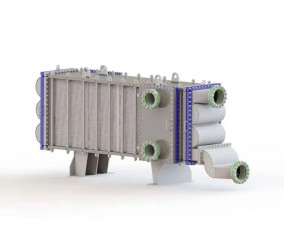

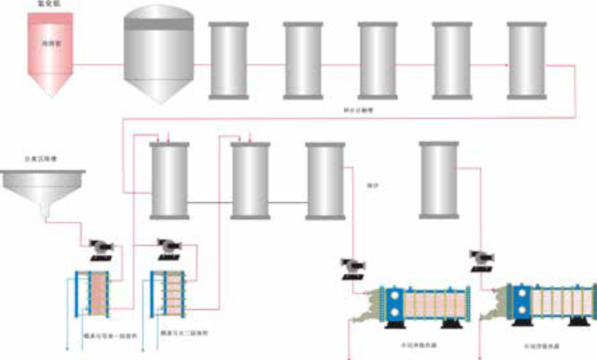

I-Alumina, ikakhulukazi i-sand alumina, iyinto eluhlaza yokuhlanza i-alumina electrolysis. Inqubo yokukhiqiza i-alumina ingahlukaniswa njengenhlanganisela ye-Bayer-sintering. Ukusetshenziswa kwe-plate heat exchanger embonini ye-alumina kunciphisa ngempumelelo ukuguguleka nokuvaleka, okwakhulisa ukusebenza kahle kwe-heat exchanger kanye nokusebenza kahle kokukhiqiza.

Ama-plate heat exchangers asetshenziswa njengokupholisa kwe-PGL, ukupholisa i-agglomeration kanye nokupholisa phakathi kwesiteji.

I-heat exchanger isetshenziswa esigabeni se-workshop sokwehla kwezinga lokushisa eliphakathi nendawo emsebenzini wokubola nokulinganisa enqubweni yokukhiqiza i-alumina, efakwe phezulu noma phansi kwethangi lokubola futhi isetshenziselwa ukunciphisa izinga lokushisa le-aluminium hydroxide slurry enqubweni yokubola.