Introduction

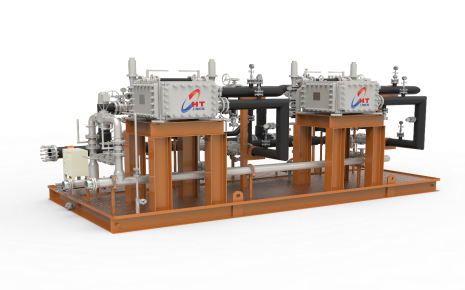

A plate heat exchanger skid is an integrated system featuring a plate heat exchanger as its core component, combined with pumps, valves, instruments, piping, and a PLC control system, all pre-installed on a steel base skid. This modular system can be easily transported, positioned, and connected to other equipment via flanges for immediate use.

By leveraging modular integration, factory pre-assembly, and intelligent management, plate heat exchanger skids solve the traditional challenges of complex installation, difficult maintenance, and poor adaptability. They have become a critical solution in industries such as marine, oil and gas, chemical processing, and renewable energy. Their core value lies in improving construction efficiency and reducing lifecycle costs, especially in harsh environments, rapid deployment scenarios, or space-constrained settings.

Key Applications of Plate Heat Exchanger Skids in Marine Engineering:

Seawater Cooling Systems

On large vessels like cruise ships, LNG carriers, and container ships, massive amounts of heat are generated by engines and machinery. High-temperature freshwater circulates to absorb this heat and then transfers it to low-temperature freshwater via plate heat exchanger skids. The low-temperature water is subsequently cooled by seawater in seawater coolers, maintaining optimal operating temperatures for the ship’s equipment.

Freshwater Supply Systems

On offshore platforms, plate heat exchanger skids play a vital role in the seawater desalination process. Before reverse osmosis treatment, seawater is heated to optimal temperatures using a heat exchanger skid to improve membrane efficiency. After desalination, the freshwater can also be cooled or heated as needed to meet living and production requirements.

HVAC Systems

Plate heat exchanger skids are crucial in marine HVAC systems. They facilitate the transfer of heat for indoor climate control: heating interior spaces in winter by transferring heat from hot water to air, and cooling spaces in summer by transferring indoor heat to chilled water, ensuring a comfortable living and working environment on offshore platforms.

Crude Oil Processing Systems

In offshore oil extraction, crude oil often contains large amounts of water and impurities. Before dewatering and desalting, plate heat exchanger skids preheat the crude oil to improve processing efficiency. After treatment, the oil is cooled by skids for easier storage and transport.

Hydraulic Systems

Marine engineering relies heavily on hydraulic machinery, including cranes and drilling equipment. During operation, hydraulic oil heats up due to friction. Plate heat exchanger skids dissipate this heat, maintaining stable oil temperatures and ensuring the reliability and performance of hydraulic systems.

Marine Aquaculture Facilities

In marine aquaculture, especially for temperature-sensitive species, removable plate heat exchanger skids are used to control water temperatures. By exchanging heat between hot/cold water and seawater, optimal breeding conditions are maintained in indoor aquaculture tanks.

Conclusion

Space and load capacity are major constraints on offshore platforms. Plate heat exchanger skids, with their compact, lightweight, easy-to-maintain design, significantly contribute to the rapid development and operational efficiency of marine engineering projects.

Post time: Mar-15-2025