Isingeniso

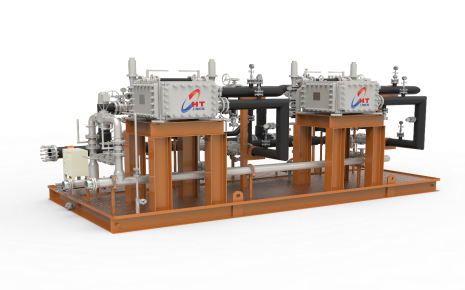

A umshini wokushintshanisa ukushisa kwepuletii-skid iyisistimu ehlanganisiwe ene-plate heat exchanger njengengxenye yayo eyinhloko, ehlanganiswe namaphampu, ama-valve, izinsimbi, amapayipi, kanye nesistimu yokulawula ye-PLC, konke kufakwe kusengaphambili ku-skid yesisekelo sensimbi. Lolu hlelo oluyi-modular lungathuthwa kalula, lubekwe endaweni, futhi luxhunywe kweminye imishini ngama-flange ukuze lusetshenziswe ngokushesha.

Ngokusebenzisa ukuhlanganiswa kwe-modular, ukuhlanganiswa kwangaphambili kwefektri, kanye nokuphathwa okuhlakaniphile, ama-skid okushintshanisa ukushisa kwamapuleti axazulula izinselele zendabuko zokufakwa okuyinkimbinkimbi, ukulungiswa okunzima, kanye nokungaguquguquki kahle. Aye aba yisisombululo esibalulekile ezimbonini ezifana nezasolwandle, uwoyela negesi, ukucubungula amakhemikhali, kanye namandla avuselelekayo. Inani lawo eliyinhloko lisekuthuthukiseni ukusebenza kahle kokwakha kanye nokunciphisa izindleko zomjikelezo wokuphila, ikakhulukazi ezindaweni ezinzima, izimo zokuthunyelwa okusheshayo, noma izilungiselelo ezivinjiwe isikhala.

Izicelo Eziyinhloko Ze-Plate Heat Exchanger Skids ku-Marine Engineering:

Izinhlelo Zokupholisa Amanzi Olwandle

Emikhumbi emikhulu efana nemikhumbi yokuhamba ngesikebhe, izithwali ze-LNG, kanye nemikhumbi yezitsha, kukhiqizwa ukushisa okukhulu yizinjini nemishini. Amanzi ahlanzekile anokushisa okuphezulu ayajikeleza ukuze amunce lokhu kushisa bese ekudlulisela emanzini ahlanzekile anokushisa okuphansi ngokusebenzisa ama-plate heat exchanger skids. Amanzi anokushisa okuphansi kamuva apholiswa ngamanzi olwandle kuma-cooler amanzi olwandle, okugcina amazinga okushisa afanele kakhulu emishini yomkhumbi.

Izinhlelo Zokunikeza Amanzi Ahlanzekile

Ezinkundleni zasogwini, ama-skid okushintshanisa ukushisa kwamapuleti adlala indima ebalulekile enqubweni yokususa usawoti emanzini olwandle. Ngaphambi kokwelashwa kwe-reverse osmosis, amanzi olwandle afudunyezwa afike emazingeni okushisa afanele kusetshenziswa i-skid yokushintshanisa ukushisa ukuze kuthuthukiswe ukusebenza kahle kwe-membrane. Ngemva kokususa usawoti emanzini, amanzi ahlanzekile angapholiswa noma afudunyezwe njengoba kudingeka ukuze kuhlangatshezwane nezidingo zokuphila nezokukhiqiza.

Izinhlelo ze-HVAC

Ama-skid okushintshanisa ukushisa kwamapuleti abalulekile ezinhlelweni ze-HVAC zasolwandle. Asiza ekudluliseni ukushisa ukuze kulawulwe isimo sezulu sangaphakathi: ukufudumeza izindawo zangaphakathi ebusika ngokudlulisa ukushisa kusuka emanzini ashisayo kuya emoyeni, kanye nezindawo ezipholile ehlobo ngokudlulisela ukushisa kwangaphakathi emanzini abandayo, okuqinisekisa indawo yokuhlala neyokusebenza ethokomele ezindaweni ezikude nolwandle.

Izinhlelo Zokucubungula Uwoyela Ongcolile

Ekukhishweni kukawoyela olwandle, uwoyela ongahluziwe uvame ukuba namanzi amaningi kanye nokungcola. Ngaphambi kokukhipha amanzi nokuwasusa usawoti, ama-plate heat exchanger skid afudumeza uwoyela ongahluziwe ukuze kuthuthukiswe ukusebenza kahle kokucubungula. Ngemva kokwelashwa, uwoyela upholiswa ama-skid ukuze kube lula ukugcina nokuthuthwa.

Izinhlelo ze-Hydraulic

Ubunjiniyela bemikhumbi buthembele kakhulu emishinini ye-hydraulic, okuhlanganisa ama-crane nemishini yokubhoboza. Ngesikhathi sokusebenza, uwoyela we-hydraulic uyashisa ngenxa yokungqubuzana. Ama-skid e-plate heat exchanger asusa lokhu kushisa, agcine amazinga okushisa kawoyela azinzile futhi aqinisekise ukuthembeka nokusebenza kwezinhlelo ze-hydraulic.

Izindawo Zokufuya Izinhlanzi Zasolwandle

Ekufuyweni kwezinhlanzi zasolwandle, ikakhulukazi ezinhlotsheni ezizwela izinga lokushisa, ama-skid okushintshanisa ukushisa kwamapuleti asuswayo asetshenziswa ukulawula izinga lokushisa kwamanzi. Ngokushintshanisa ukushisa phakathi kwamanzi ashisayo/abandayo namanzi olwandle, izimo zokuzalanisa ezifanele zigcinwa emathangini okufuywa kwezinhlanzi angaphakathi.

Isiphetho

Isikhala kanye nomthamo womthwalo kuyimingcele emikhulu kumapulatifomu asogwini lolwandle. Ama-skid okushintshanisa ukushisa kwamapuleti, anomklamo wawo omncane, olula, nolula ukuwunakekela, anegalelo elikhulu ekuthuthukisweni okusheshayo kanye nokusebenza kahle kwamaphrojekthi obunjiniyela basolwandle.

Isikhathi sokuthunyelwe: Mashi-15-2025