In today's alumina industry, the demand for production efficiency and environmental protection is continuously increasing, leading to a growing need for efficient and reliable industrial equipment. Especially in the field of heat exchange, traditional plate heat exchangers face numerous challenges, such as being prone to clogging and difficult to clean and maintain. To address these issues, the vertical wide channel plate heat exchanger has emerged as the ideal solution.

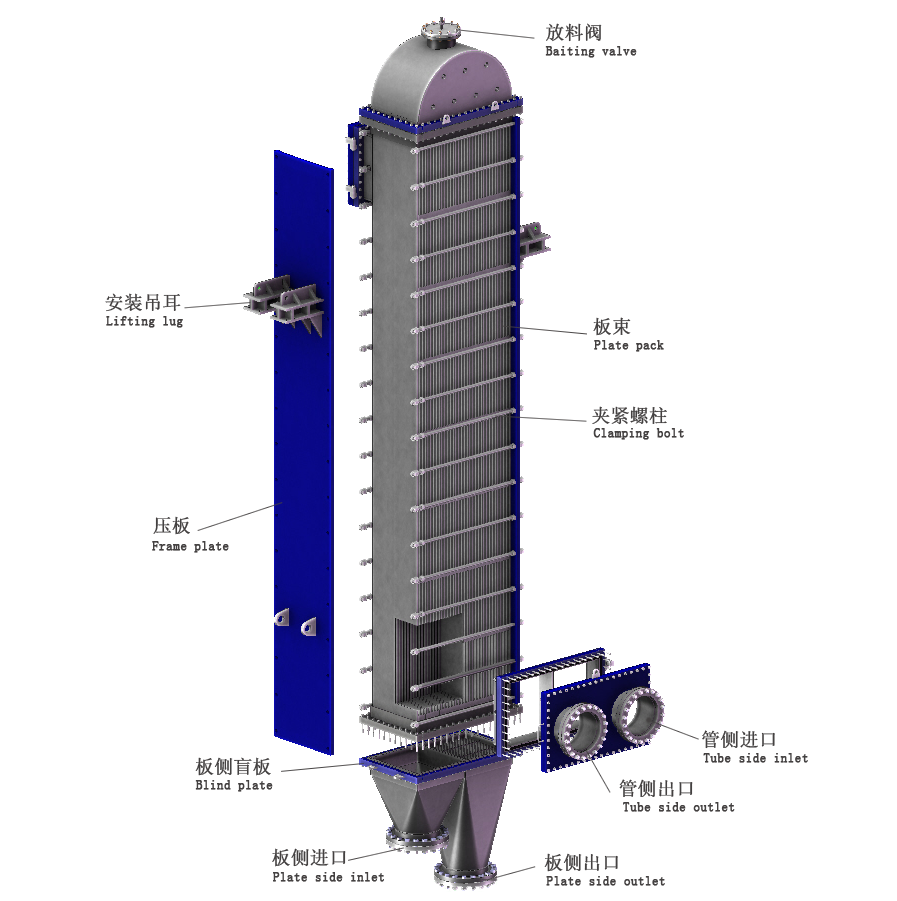

The vertical wide channel plate heat exchanger employs an innovative design concept. Its unique vertical placement and wide channel design effectively solve the common problems of heat exchanger clogging and cleaning difficulties in the alumina industry. This design not only maintains the traditional advantage of high heat transfer efficiency of plate heat exchangers but also significantly enhances the reliability and maintenance convenience of the equipment, providing strong technical support for the sustainable development of the alumina industry.

Technical Features and Advantages:

High Heat Transfer Efficiency: Through advanced fluid dynamics design, the vertical wide channel plate heat exchanger achieves higher heat transfer efficiency and lower pressure drop. Its unique plate structure optimizes the flow path of the thermal fluid, ensuring maximum heat exchange efficiency.

Anti-clogging Design: Traditional plate heat exchangers are prone to clogging due to the deposition of particles within the flow channels. The design of the vertical wide channel plate heat exchanger ensures smoother solid-liquid flow, with the direction of gravity aligned with the flow direction, significantly reducing the possibility of sediment formation and effectively preventing clogging.

Easy Cleaning and Maintenance: The vertical structure and wide channel design make cleaning and maintenance tasks much easier. Even after long periods of operation, cleaning can be performed quickly and conveniently, significantly reducing maintenance costs and downtime.

Strong Adaptability: The vertical wide channel plate heat exchanger can handle heat exchange requirements involving media with more solid particles or higher viscosity, suitable for a variety of complex conditions in the alumina industry.

Environmental Protection and Energy Saving: By improving heat exchange efficiency and reducing maintenance downtime, the vertical wide channel plate heat exchanger not only ensures production efficiency but also reduces energy consumption and operational costs, meeting the green development needs of the industrial sector.

In the alumina industry, the application of the vertical wide channel plate heat exchanger not only enhances production efficiency and lowers maintenance costs but also provides enterprises with more stable and reliable production assurance. Shanghai Heat Transfer Equipment Co., Ltd., as a professional heat exchanger manufacturer, is committed to providing efficient, reliable, and environmentally friendly heat exchange solutions for the alumina industry and beyond. Choosing our vertical wide channel plate heat exchanger is a wise decision for achieving high production efficiency and reducing operational costs.

Post time: Mar-25-2024