Embonini ye-alumina yanamuhla, isidingo sokusebenza kahle kokukhiqiza kanye nokuvikelwa kwemvelo sikhula njalo, okuholela esidingweni esikhulayo semishini yezimboni esebenza kahle nethembekile. Ikakhulukazi emkhakheni wokushintshana kokushisa, ama-plate exchanger endabuko abhekene nezinselele eziningi, njengokuthambekela ekuvalekeni kanye nobunzima bokuhlanza nokunakekela. Ukuze kuxazululwe lezi zinkinga,isiteshi esibanzi esiqondile esishintsha ukushisa kwepuletisekuvele njengesixazululo esifanele.

Iisiteshi esibanzi esiqondile esishintsha ukushisa kwepuletiisebenzisa umqondo womklamo omusha. Ukubekwa kwayo okuqondile okuhlukile kanye nomklamo wesiteshi esibanzi kuxazulula ngempumelelo izinkinga ezivamile zokuvalwa kwe-heat exchanger kanye nobunzima bokuhlanza embonini ye-alumina. Lo mklamo awugcini nje ngokugcina inzuzo yendabuko yokusebenza kahle kokudlulisa ukushisa okuphezulu kwama-plate heat exchangers kodwa futhi uthuthukisa kakhulu ukuthembeka nokugcinwa kwemishini, unikeza ukwesekwa okuqinile kwezobuchwepheshe kwentuthuko esimeme yomkhakha we-alumina.

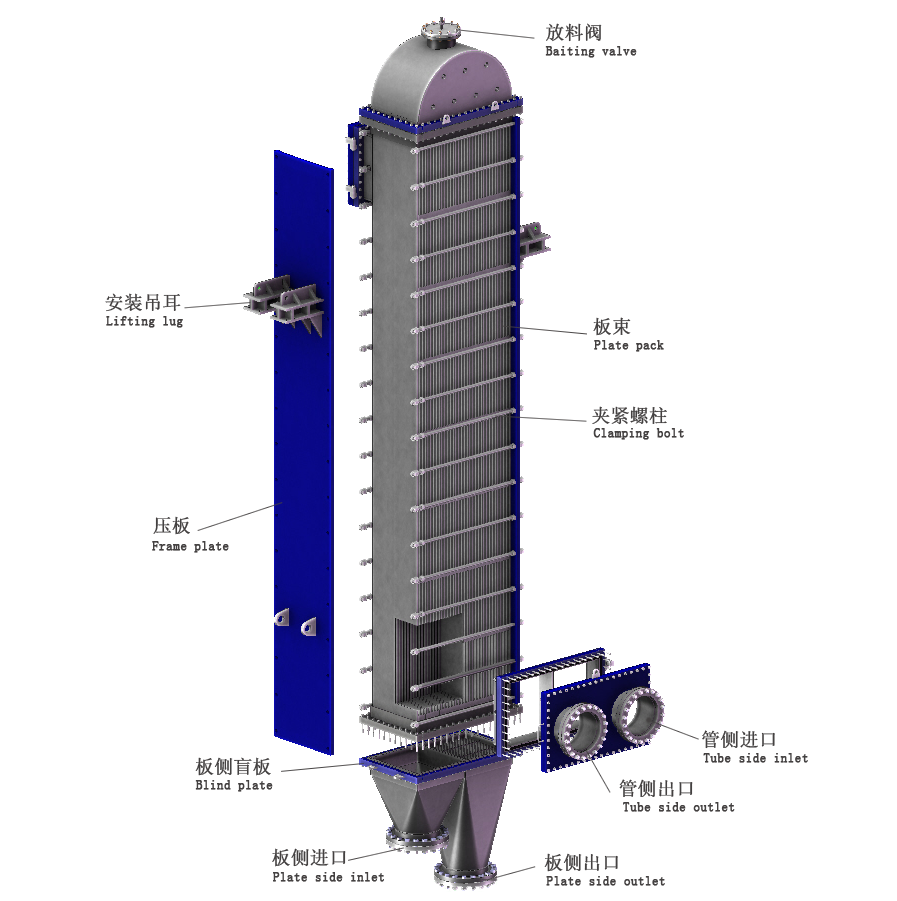

Izici Zobuchwepheshe Nezinzuzo:

Ukusebenza Kahle Kokudlulisa Ukushisa Okuphezulu: Ngomklamo othuthukisiwe we-fluid dynamics,isiteshi esibanzi esiqondile esishintsha ukushisa kwepuletiifinyelela ukusebenza kahle kokudlulisa ukushisa okuphezulu kanye nokwehla kwengcindezi okuphansi. Isakhiwo sayo esiyingqayizivele sepuleti senza ngcono indlela yokugeleza koketshezi lokushisa, siqinisekise ukusebenza kahle kokushintshana kokushisa okuphezulu.

Umklamo Ovimbela Ukuvaleka: Ama-plate exchanger okushisa endabuko avame ukuvaleka ngenxa yokuminyana kwezinhlayiya ngaphakathi kweziteshi zokugeleza. Umklamo we-vertical wide channel plate heat exchanger uqinisekisa ukugeleza okubushelelezi koketshezi oluqinile, kanye nesiqondiso samandla adonsela phansi esihambisana nesiqondiso sokugeleza, okunciphisa kakhulu amathuba okwakheka kwenhlabathi futhi kuvimbele ngempumelelo ukuvaleka.

Ukuhlanza Nokulungisa Okulula: Isakhiwo esiqondile kanye nomklamo wesiteshi esibanzi kwenza imisebenzi yokuhlanza nokulungisa ibe lula kakhulu. Ngisho nangemva kwesikhathi eside sokusebenza, ukuhlanza kungenziwa ngokushesha nangokulula, kunciphisa kakhulu izindleko zokulungisa kanye nesikhathi sokungasebenzi.

Ukuzivumelanisa Nezimo Okuqinile: I-vertical wide channel plate heat exchanger ingaphatha izidingo zokushintshana kokushisa ezihilela imidiya enezinhlayiya eziqinile noma i-viscosity ephezulu, efanelekile ezimweni ezahlukahlukene eziyinkimbinkimbi embonini ye-alumina.

Ukuvikelwa Kwemvelo Nokonga Amandla: Ngokuthuthukisa ukusebenza kahle kokushintshana kokushisa nokunciphisa isikhathi sokulungisa, i-vertical wide channel plate heat exchanger ayiqinisekisi nje kuphela ukusebenza kahle kokukhiqiza kodwa futhi inciphisa ukusetshenziswa kwamandla nezindleko zokusebenza, ihlangabezana nezidingo zokuthuthukiswa okuluhlaza zomkhakha wezimboni.

Embonini ye-alumina, ukusetshenziswa kwe-vertical wide channel plate heat exchanger akugcini nje ngokuthuthukisa ukusebenza kahle kokukhiqiza futhi kwehlisa izindleko zokulungisa kodwa futhi kunikeza amabhizinisi isiqinisekiso sokukhiqiza esizinzile nesinokwethenjelwa.I-Shanghai Heat Transfer Equipment Co., Ltd., njengomkhiqizi wobuchwepheshe bokushintshanisa ukushisa, uzibophezele ekuhlinzekeni ngezixazululo zokushintshanisa ukushisa ezisebenzayo, ezithembekile, nezinobungani nemvelo embonini ye-alumina nangale kwayo. Ukukhetha i-vertical wide channel plate heat exchanger yethu kuyisinqumo esihlakaniphile sokufeza ukusebenza kahle kokukhiqiza kanye nokunciphisa izindleko zokusebenza.

Isikhathi sokuthunyelwe: Mashi-25-2024