Izitshintshi zobushushu zepleyiti ezidityanisiweyo zizinto ezibalulekileyo kwiinkqubo ezahlukeneyo zoshishino, zibonelela ngezisombululo zolawulo lobushushu ezisebenzayo. Eli nqaku liza kujonga kwiingxaki zezitshintshi zobushushu zepleyiti ezidityanisiweyo, lihlola uyilo lwazo, iingenelo, iindlela zokusebenza, kunye nokusetyenziswa kwazo ezahlukeneyo. Ngokuqonda ezi zinto, iingcali zinokwenza izigqibo ezinolwazi zokuphucula iinkqubo zazo zobushushu ngokufanelekileyo.

Yintoni iI-Welded Plate Heat Exchanger?

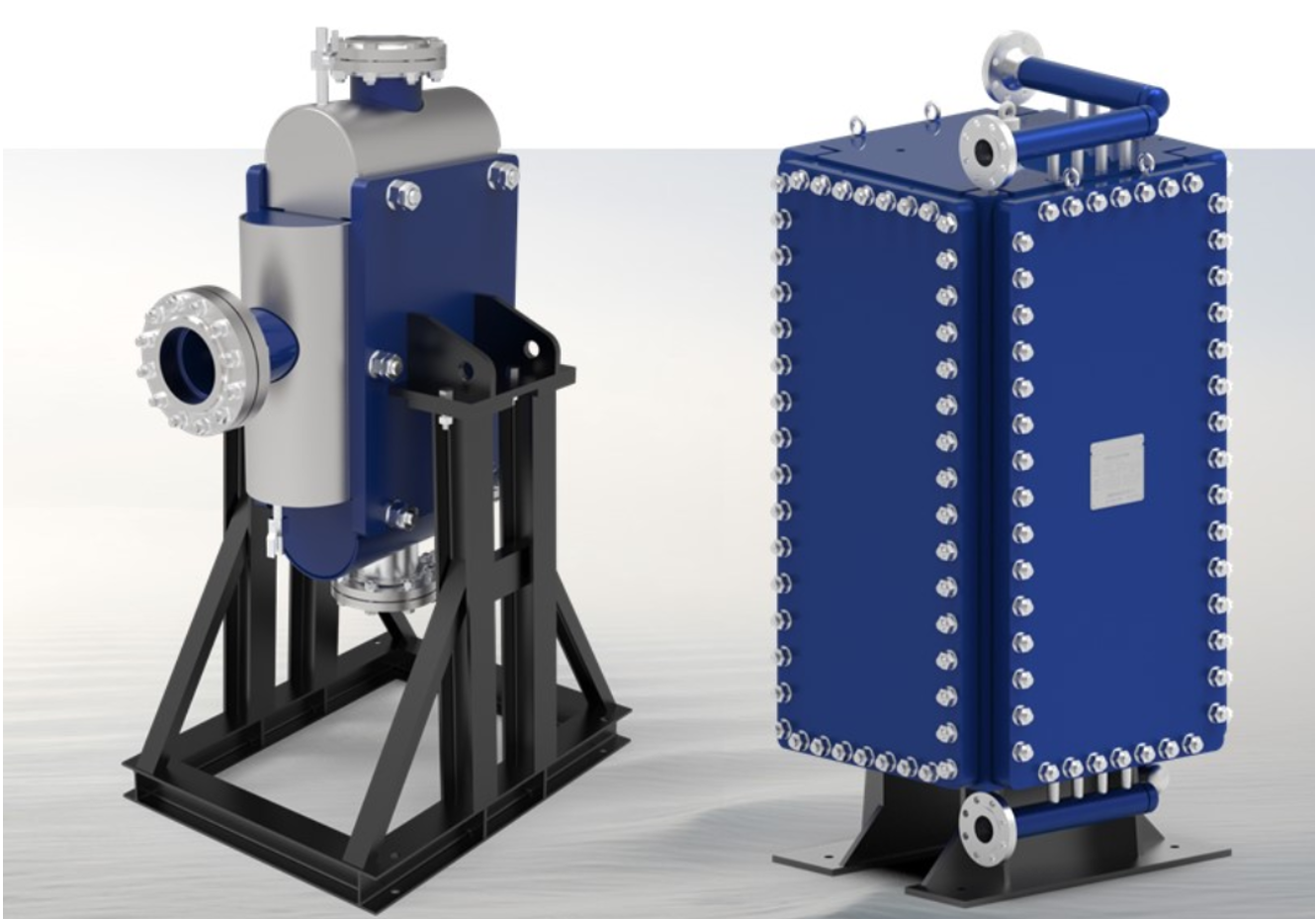

I-welded plate heat exchanger (WPHE) luhlobo lwe-heat exchanger olusebenzisa iipleyiti ezininzi ezincinci, ezihlanganisiweyo ezidityanisiweyo ukuze kube lula ukudluliselwa kobushushu phakathi kolwelo olubini. Ngokungafaniyo ne-heat exchangers zemveli ze-shell-and-tube, ii-WPHE zibonelela ngokusebenza okuphuculweyo kobushushu, uyilo oluncinci, kunye nokuguquguquka ekuphatheni iintlobo ezahlukeneyo zolwelo.

Izinto eziphambili zeI-Welded Plate Heat Exchanger

1.Iipleyiti zeCorrugated: Ezi plate zineendlela ezintsonkothileyo ezandisa indawo yomphezulu yokutshintshiselana kobushushu, nto leyo ekhuthaza ukudluliselwa kobushushu okusebenzayo.

2.Ukuwelda: Ngokuxhomekeke kuyilo, iipleyiti ziyadityaniswa ukuze kuthintelwe ukuvuza kolwelo nokuqinisekisa ukuqina.

3.Izigqubuthelo zesakhelo kunye nesiphelo: Indibano igcinwe kwisakhelo okanye iqokobhe eliqinileyo, kunye nezigqubuthelo zokugqibela ezivumela ukungena nokuphuma kolwelo.

4.Indlela yokutywina: Iqinisekisa ukuba la manzi mabini ahlala ahlukene, nto leyo ethintela ungcoliseko oludibanayo.

Uyilo kunye nokwakhiwa kweeWelded Plate Heat Exchangers

Uyilo lwee-WPHE lubalulekile ekusebenzeni kwazo nasekuphileni ixesha elide. Izinto eziphambili ekufuneka ziqwalaselwe kuyilo ziquka:

Uqwalaselo lwePlate

● Iipateni zoKorrugation: Uyilo lwee-corrugations zeplate luchaphazela ukuhamba kolwelo kunye nokusebenza kakuhle kokudluliselwa kobushushu. Iipateni eziqhelekileyo ziquka iChevron, iWave, kunye neHerringbone.

● Ubukhulu bepleyiti: Iipleyiti ezincinci zibonelela ngamazinga aphezulu okudlulisa ubushushu kodwa zifuna ukwenziwa okuchanekileyo ukuze kugcinwe ulungelelwaniso lwesakhiwo.

Ukukhetha Izinto

● Yenziwe ngentsimbi eshayinayo: Ikhethwa ngenxa yokumelana kwayo nokugqwala kunye nokuqina kwayo, ingakumbi kwiindawo ezirhabaxa.

● I-Titanium: Isetyenziswa kwizicelo ezifuna ukumelana nokugqwala okuphezulu, njengakwiinkqubo zamanzi olwandle.

● Ii-Nickel Alloys: Ikhethelwe ukusetyenziswa kumaqondo obushushu aphezulu ngenxa yokuqhuba kwayo kakuhle kobushushu.

Iindlela zokuWelda

● Ukuwelda kweFusion: Iqinisekisa unxibelelwano olungenamthungo phakathi kweepleyiti, isusa iindawo ezinokubangela ukuvuza.

● Ukuwelda kokumelana: Isetyenziselwa ukudibanisa iipleyiti ngokufanelekileyo, ingakumbi kwiimeko zemveliso eninzi.

Uyilo lweThermal

● Ii-Coefficients zokudlulisa ubushushu: Yenzelwe uyilo lwepleyiti ukuze kuphuculwe utshintshiselwano lobushushu.

● Ulungiselelo lokuhamba komoya: Ilungiselelwe ukuhamba okuchaseneyo okanye ukuhamba okuhamba ngaxeshanye ukuphucula ukusebenza kakuhle kokudluliselwa kobushushu.

Iingenelo zeIzitshintshi zobushushu zePlate eziWelded

Izitshintshi zobushushu zepleyiti eziwelding zibonelela ngeenzuzo ezininzi ezizenza zibe lukhetho olukhethwayo kumashishini ahlukeneyo:

Ukusebenza kakuhle kweThermal ephezulu

Uyilo oluntsonkothileyo lwepleyiti kunye nommandla ophezulu womphezulu kwenza kube lula ukudlulisa ubushushu obuphezulu xa kuthelekiswa nezixhobo zokutshintshiselana ubushushu zemveli.

Incinci kwaye ilula

IiWPHE zincinci kakhulu, nto leyo eyenza ukuba zilungele ukufakwa kwiindawo ezinqongopheleyo.

Ukuguquguquka

Ifanelekile kwiintlobo ngeentlobo zeziselo, kuquka neziselo ezirhabaxa nezishushu kakhulu, nto leyo ephucula ukusebenza kwazo kumacandelo ahlukeneyo.

Ukugcinwa okulula

Uyilo lweModular luvumela ukucoca nokulungisa izinto ngokulula, kunciphisa ixesha lokungasebenzi kunye nokuphazamiseka kokusebenza.

Ukuqina kunye nokuthembeka

Ulwakhiwo oludibeneyo luqinisekisa ukusebenza kakuhle nokuqina, nokuba phantsi kweemeko ezinzima.

Indlela yokusebenza yeeWelded Plate Heat Exchangers

Ukuqonda imigaqo yokusebenza ye-WPHEs kubalulekile ekwenzeni ngcono ukusebenza kwazo:

Iintshukumo zokuhamba kolwelo

Ii-WPHE zisebenza ngokukhokela ulwelo olubini olwahlukeneyo ngeendlela ezahlukeneyo ezenziwe ziipleyiti ezigobileyo. Ezi corrugations zibangela ingxolo, ziphucula ukusebenza kakuhle kokudlulisa ubushushu ngokuphazamisa umaleko womda.

Inkqubo yokuDlulisa ubushushu

Ubushushu budluliselwa ukusuka kulwelo olushushu ukuya kulwelo olupholileyo ngokusebenzisa izinto zepleyiti. Ukusebenza kakuhle kuphenjelelwa zizinto ezifana nommandla womphezulu wepleyiti, isantya solwelo, kunye nobushushu obuphezulu.

Izinto ekufuneka uziqwalasele xa ucima uxinzelelo

Nangona ii-WPHE zibonelela ngokusebenza kakuhle kobushushu, zinokufumana ukwehla koxinzelelo oluphezulu ngenxa yoyilo lwepleyiti ebotshelelweyo. Uyilo olufanelekileyo lwenkqubo kunye nohlalutyo lwe-fluid dynamics kubalulekile ukunciphisa esi siphumo.

Izicelo zeWelded Plate Heat Exchangers

Izitshintshi zobushushu zepleyiti eziwelding zisetyenziswa kumashishini ahlukeneyo ngenxa yokusebenza kakuhle kunye nokuguquguquka kwazo:

Ukucubungula iikhemikhali

Ii-WPHE zisetyenziselwa ukubuyisela ubushushu, ukulawula ubushushu, kunye nokufudumeza i-reaction, zilawula iikhemikhali ezibolayo ngokufanelekileyo.

Ukutya neZiselo

Iqinisekisa ulawulo oluchanekileyo lobushushu ngexesha lokucubungula kunye nokupakisha, igcina umgangatho kunye nokhuseleko lwemveliso.

Ukuveliswa koMbane

Ndisebenza kwiinkqubo zokupholisa kunye nokubuyisela ubushushu obulahlekileyo, nto leyo enegalelo ekwenzeni ngcono amandla ngokubanzi.

Ioyile kunye neGesiIshishini

Iphatha ulwelo olushushu kakhulu nolunoxinzelelo oluphezulu, iqinisekisa ukusebenza okuthembekileyo kwiindawo ezifuna kakhulu.

Ukugcinwa kunye nokusombulula iingxaki

Ukugcinwa rhoqo kubalulekile ukuqinisekisa ukusebenza kakuhle kwee-welded plate heat exchangers. Iindlela eziphambili zokulungisa ziquka:

Uhlolo oluQhelekileyo

Jonga iimpawu zokugqwala, ukuvuza, kunye nomonakalo weepleyiti ukuze ulungise iingxaki ngokukhawuleza.

Iinkqubo zokucoca

Sebenzisa iindlela zokucoca rhoqo ukuze ususe ukungcola kunye nokukhula, ugcine ukusebenza kakuhle kokudlulisa ubushushu.

Uvavanyo loxinzelelo

Yenza uvavanyo loxinzelelo ukuqinisekisa ukuthembeka kwee-welds kunye nee-seals, ukuthintela ukuvuza okunokwenzeka.

Ukusombulula iingxaki eziqhelekileyo

● Ukunciphisa ukusebenza kakuhle kokudlulisa ubushushu: Idla ngokubangelwa kukungcoliswa okanye ukukrwela; ukucoca rhoqo kunokunciphisa oku.

● Ukwehla koxinzelelo okwandileyo: Ingabangelwa ziitshaneli ezivaliweyo okanye iipleyiti ezonakeleyo; ukuhlola nokutshintsha iipleyiti ezichaphazelekileyo kungayisombulula le nto.

● UkuvuzaNgokuqhelekileyo kungenxa yokuba kukho ii-welds okanye izitywini ezingasebenzi kakuhle; ukuchonga nokulungisa ukuvuza ngokukhawuleza kubalulekile ukuze kugcinwe ukuthembeka kwenkqubo.

Iindlela Zekamva kwiTekhnoloji yeWelded Plate Heat Exchanger

Ukuqhubela phambili kwezixhobo kunye neendlela zokuvelisa kuqhuba uphuhliso lwe-WPHEs:

Izinto eziphuculweyo

Uphuhliso lwee-alloys ezintsha kunye nezinto ezidityanisiweyo lubonelela ngokumelana nokugqwala okuphuculweyo kunye nokusebenza kobushushu.

Iinkqubo zoKubeka esweni ngoBulumko

Ukuhlanganiswa kwe-IoT, i-AI kunye netekhnoloji ye-sensor kwenza kube lula ukujonga ngexesha langempela kunye nokugcinwa kwangaphambili, okuphucula ukusebenza kakuhle.

Uyilo Olusebenzisa Amandla Ngendlela Efanelekileyo

Utshintsho kwi-plate geometry kunye ne-flow dynamics lujolise ekwandiseni ukusebenza kakuhle kobushushu ngelixa kunciphisa ukusetyenziswa kwamandla.

Uveliso oluZinzileyo

Ukwamkelwa kweenkqubo zokuvelisa ezinobuhlobo nokusingqongileyo kuhambelana neenjongo zozinzo lwehlabathi, kunciphisa impembelelo yokusingqongileyo yemveliso ye-WPHE.

Isiphelo

Izitshintshi zobushushu zepleyiti ezidityanisiweyozibaluleke kakhulu kwizicelo zoshishino zanamhlanje, zibonelela ngokusebenza kakuhle kobushushu, uyilo oluncinci, kunye nokuguquguquka. Ukuqonda uyilo lwazo, iingenelo, iindlela zokusebenza, kunye neemfuno zolondolozo kwenza amashishini akwazi ukusebenzisa amandla awo apheleleyo, ukuqinisekisa ukusebenza kakuhle kunye nokuthembeka. Njengoko iteknoloji iqhubeka ihambela phambili, ii-WPHE ziya kudlala indima ebaluleke ngakumbi kwizisombululo zolawulo lobushushu ezizinzileyo nezisebenzayo.

Ixesha leposi: Februwari-21-2025