Zvishandiso zvekupisa zveplate zvakasungirirwa zvinhu zvakakosha mumaindasitiri akasiyana-siyana, zvichipa mhinduro dzinoshanda dzekutarisira kupisa. Chinyorwa chino chinotarisa zvakadzama zvezvishandiso zvekupisa zveplate zvakasungirirwa, zvichiongorora magadzirirwo azvo, zvakanakira, mashandiro azvo, uye mashandisirwo akasiyana-siyana. Nekunzwisisa zvinhu izvi, nyanzvi dzinogona kuita sarudzo dzakangwara dzekugadzirisa masisitimu avo ekupisa zvinobudirira.

Chii chinonziWelded Plate Heat Exchanger?

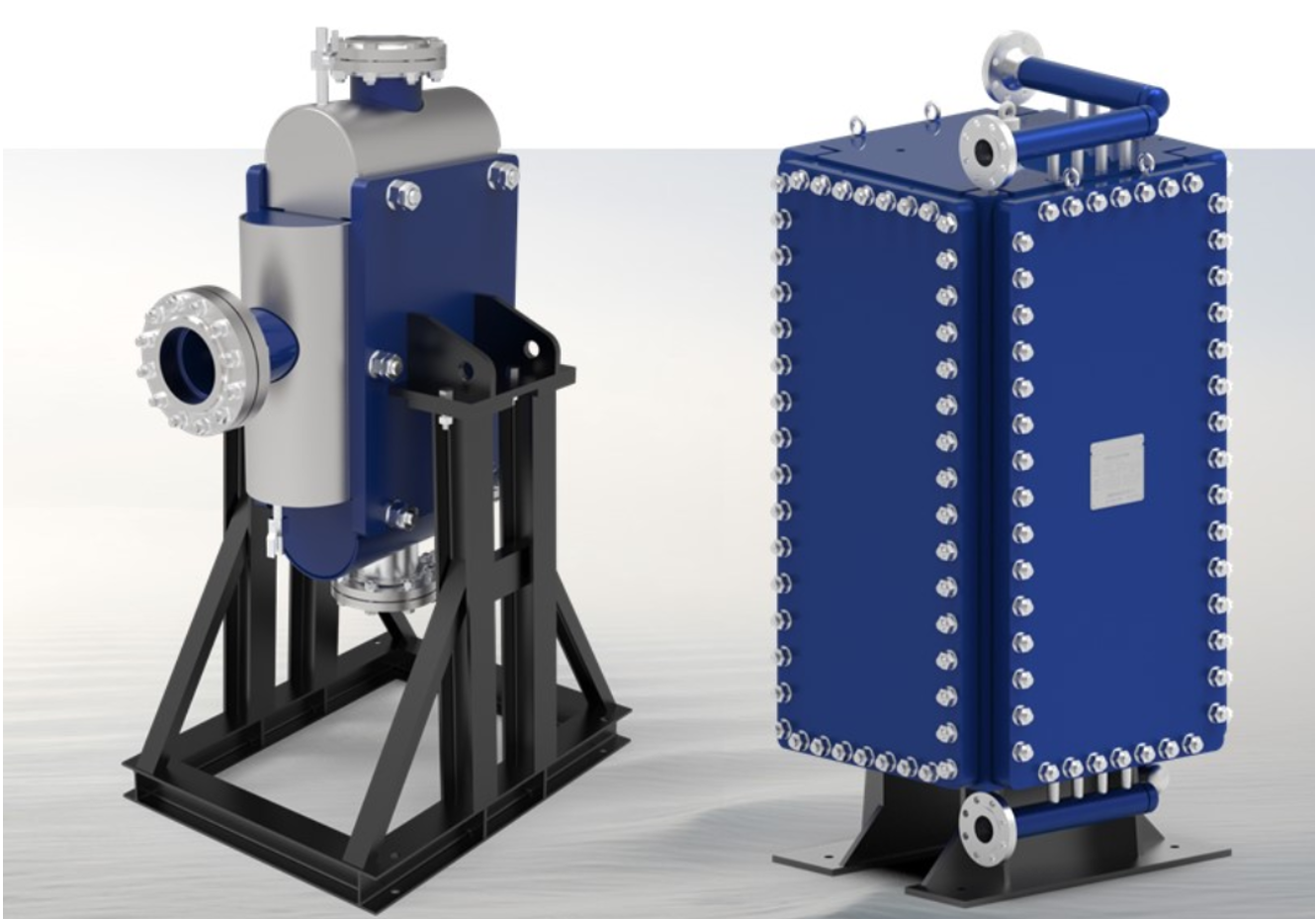

Chinochinjisa kupisa kwemaplate chakasungirirwa (WPHE) imhando yechichinjisa kupisa chinoshandisa maplate akawanda matete, akasungirirwa pamwe chete kuti zvive nyore kutamisa kupisa pakati pemvura mbiri. Kusiyana nezvichinjisa kupisa zvechinyakare zvegoko nechubhu, maWPHE anopa kushanda kwakanaka kwekupisa, dhizaini diki, uye hunyanzvi mukubata mhando dzakasiyana dzemvura.

Zvikamu Zvikuru zveWelded Plate Heat Exchanger

1.Mahwendefa eCorrugated: Maplate aya ane mapatani akaomarara anowedzera nzvimbo yekuchinjana kupisa, zvichikurudzira kutamiswa kwekupisa kunoshanda.

2.Kushongedza: Zvichienderana nekugadzirwa, maplate anosungirirwa kudzivirira kubuda kwemvura uye kuve nechokwadi chekuti anogara kwenguva refu.

3.Furemu uye Mafuremu Ekupedzisira: Chigadziko chacho chinoiswa mukati mefuremu yakasimba kana goko, nemavharo ekupedzisira achibatsira kupinda nekubuda kwemvura.

4.Chisimbiso Chekushandisa: Inoita shuwa kuti mvura mbiri idzi dzinoramba dzakaparadzana, zvichidzivirira kusvibiswa kwemvura.

Kugadzira nekuvaka Welded Plate Heat Exchangers

Kugadzirwa kweWPHE kwakakosha pakushanda kwavo uye kurarama kwenguva refu. Zvinhu zvikuru zvekufunga nezvazvo zvinosanganisira:

Kugadziriswa kwePlate

● Maitiro eKuora: Magadzirirwo ema plate corrugations anokanganisa kuyerera kwemvura uye kushanda zvakanaka kwekutapurirana kwekupisa. Mapatani akajairika anosanganisira Chevron, Wave, uye Herringbone.

● Ukobvu hweplate: Maplate akatetepa anopa mwero wepamusoro wekutamisa kupisa asi anoda kugadzirwa kwakanyatsonaka kuti arambe akasimba.

Kusarudzwa Kwezvinhu

● Simbi isina ngura: Inonyanya kufarirwa nekuda kwekusaora kwayo uye kugara kwenguva refu, kunyanya munzvimbo dzakaoma.

● Titanium: Inoshandiswa mumabasa anoda kudzivirira ngura zvakanyanya, senge muzvirongwa zvemvura yegungwa.

● Nickel Alloys: Yakasarudzwa kuti ishandiswe pakupisa kwakanyanya nekuda kwekushanda kwayo zvakanaka kwekupisa.

Maitiro Ekushongedza

● Kubatanidza Kushongedza: Inovimbisa kubatana kwakanaka pakati pemaplate, ichibvisa nzvimbo dzinogona kubuda mvura.

● Kudzivirira Kushongedza: Inoshandiswa kubatanidza maplate zvinobudirira, kunyanya mumamiriro ekugadzirwa akawanda.

Dhizaini yeThermal

● MaCoefficients Ekuchinjisa Kupisa: Yakagadziridzwa kuburikidza nekugadzirwa kweplate kuti iwedzere kuchinjana kwekupisa.

● Kurongeka Kwekuyerera: Yakagadzirirwa kuyerera kwemvura inoyerera kana kuyerera kwakafanana kuti iwedzere kushanda zvakanaka kwekutamisa kupisa.

Zvakanakira zveWelded Plate Heat Exchangers

Welded plate heat exchangers ine mabhenefiti akawanda anoita kuti ive sarudzo inofarirwa mumaindasitiri akasiyana siyana:

Kushanda Kwakanyanya Kwekupisa

Magadzirirwo eplate akaomarara uye nzvimbo yakawedzerwa yenzvimbo inoita kuti kupisa kupfuure nekukurumidza zvichienzaniswa nemidziyo yemazuva ano yekuchinjana kupisa.

Kakamanikana uye Kareruka

MaWPHE ane nzvimbo diki, zvichiita kuti akwanise kuiswa munzvimbo isina nzvimbo yakawanda.

Kuchinja-chinja

Yakakodzera mhando dzakasiyana dzemvura, kusanganisira zvinopisa zvakanyanya uye zvinopisa zvakanyanya, zvichiita kuti ishande zvakanaka munzvimbo dzakasiyana.

Kugadzirisa Kuri Nyore

Dhizaini yemodular inobvumira kuchenesa nekugadzirisa zviri nyore, zvichideredza nguva yekushanda uye kukanganiswa kwekushanda.

Kugara kwenguva refu uye Kuvimbika

Kuvakwa kwakabatanidzwa kunovimbisa kushanda kwakasimba uye kugara kwenguva refu, kunyangwe mumamiriro ezvinhu akaoma.

Maitiro Ekushanda KweWelded Plate Heat Exchangers

Kunzwisisa misimboti yekushanda kweWPHE kwakakosha pakuvandudza mashandiro avo:

Kuyerera Kwemvura

MaWPHE anoshanda nekutungamira mvura mbiri dzakasiyana kuburikidza nenzira dzakasiyana dzinogadzirwa nemaplate akaumbwa nesimbi. Macorrugation aya anokonzera kutenderera, zvichiwedzera kushanda zvakanaka kwekutapurirana kwekupisa nekukanganisa muganhu wechikamu.

Maitiro Ekutamisa Kupisa

Kupisa kunotamiswa kubva mumvura inopisa kuenda mumvura inotonhorera kuburikidza nezvinhu zviri muplate. Kushanda zvakanaka kunokonzerwa nezvinhu zvakaita senzvimbo yeplate, kumhanya kwemvura, uye tembiricha.

Kufunga Nezvekuderera Kwedzvinyiriro

Kunyange zvazvo maWPHE achigona kupisa zvakanyanya, anogona kudonha zvakanyanya nekuda kwekugadzirwa kweplate yakakora. Kugadzirwa kwakakodzera kwesystem uye kuongorora mafambiro emvura kwakakosha kuderedza izvi.

Mashandisirwo eWelded Plate Heat Exchangers

Zvishandiso zvekupisa zveplate zvakasungirirwa zvinoshandiswa mumaindasitiri akasiyana-siyana nekuda kwekushanda kwazvo uye kushanduka-shanduka:

Kugadziriswa kweMakemikoro

MaWPHE anoshandiswa kudzoreredza kupisa, kudzora tembiricha, uye kupisa kwemuviri, anobata makemikari anoparadza zvinobudirira.

Chikafu neChinwiwa

Inovimbisa kutonga kwakarurama kwekupisa panguva yekugadzirisa nekurongedza, ichichengetedza mhando yechigadzirwa uye kuchengetedzeka.

Kugadzira Simba

Ndinoshanda muzvirongwa zvekutonhodza uye kudzoreredza kupisa kwakarasika, zvichibatsira mukugadzirisa simba rose.

Oiri neGasiMaindasitiri

Inobata mvura inopisa zvakanyanya uye ine simba guru, zvichiita kuti ishande zvakanaka munzvimbo dzinoda simba rakawanda.

Kugadzirisa uye Kugadzirisa Matambudziko

Kugadzirisa nguva dzose kwakakosha kuti zvive nechokwadi chekuti ma welded plate heat exchangers anoshanda zvakanaka. Maitiro makuru ekugadzirisa anosanganisira:

Kuongorora Kwenguva Dzose

Tarisa kana paine zviratidzo zvekuora, kudonha kwemvura, uye kukuvara kweplate kuti ugadzirise matambudziko nekukurumidza.

Maitiro Ekuchenesa

Shandisa nzira dzekuchenesa nguva dzose kuti ubvise tsvina uye kukwenya, uchichengetedza kushanda zvakanaka kwekutapurirana kwekupisa.

Kuedzwa kweDzvinyiriro

Ita bvunzo dzekumanikidza kuti uone kana welds nezvisimbiso zviripo, kudzivirira kubuda kwemvura.

Kugadzirisa Matambudziko Akajairika

● Kuderedza Kushanda Kwekupisa: Kazhinji kunokonzerwa nekusvibiswa kana kukwenya; kucheneswa nguva dzose kunogona kuderedza izvi.

● Kuderera Kwakawedzerwa Kwekumanikidzwa: Zvinogona kukonzera migero yakavharwa kana mapurati akakuvara; kuongorora nekutsiva mapurati akakanganiswa kunogona kugadzirisa izvi.

● Kubuda kwemvura: Kazhinji kacho kunokonzerwa nekukwevera kana kuvharira kusina kunaka; kuziva nekugadzirisa kudonha kwemvura nekukurumidza kwakakosha kuchengetedza kusimba kwehurongwa.

Mafambiro Emangwana muTekinoroji yeWelded Plate Heat Exchanger

Kufambira mberi muzvinhu uye matekiniki ekugadzira kuri kutungamira kushanduka kweWPHEs:

Zvinhu Zvakavandudzwa

Kugadzirwa kwezviumbwa zvitsva zvesimbi uye zvinhu zvakasanganiswa zvinopa simba rekudzivirira ngura uye kushanda zvakanaka kwekupisa.

Masisitimu Ekutarisa Akangwara

Kubatanidzwa kweIoT, AI uye matekinoroji e sensor kunogonesa kutarisa panguva chaiyo uye kugadzirisa mafambiro ekufanotaura, zvichiwedzera kushanda zvakanaka.

Magadzirirwo Asingashandise Simba Zvikuru

Kuvandudzwa mukugadzirwa kwemaplate geometry uye mafambiro ekuyerera kwemvura kunovavarira kuwedzera kushanda zvakanaka kwekupisa ukuwo kuchideredza kushandiswa kwesimba.

Kugadzira Zvisingachinji

Kushandiswa kwemaitiro ekugadzira asingakuvadzi nharaunda kunoenderana nezvinangwa zvepasi rose zvekuchengetedza nharaunda, zvichideredza kukanganisa kwekugadzirwa kweWPHE.

Mhedziso

Zvishandiso zvekupisa zveplate zvakasungirirwaZvakakosha mukushandiswa kwemaindasitiri emazuva ano, zvichipa kushanda zvakanaka kwekupisa, dhizaini diki, uye kushanduka-shanduka. Kunzwisisa magadzirirwo azvo, zvakanakira, mashandiro ekushanda, uye zvinodiwa pakugadzirisa kunoita kuti maindasitiri akwanise kushandisa mukana wazvo wese, zvichiita kuti zvive pachena kuti mashandiro azvo akanaka uye akavimbika. Sezvo tekinoroji ichiramba ichifambira mberi, maWPHE achaita basa rakakosha mukugadzirisa kushandiswa kwekupisa kwenguva refu uye zvinobudirira.

Nguva yekutumira: Kukadzi-21-2025