Hot New Products Heat Exchanger Supplier - Wide Gap Welded Plate Heat Exchanger for Alumina refinery – Shphe

Hot New Products Heat Exchanger Supplier - Wide Gap Welded Plate Heat Exchanger for Alumina refinery – Shphe Detail:

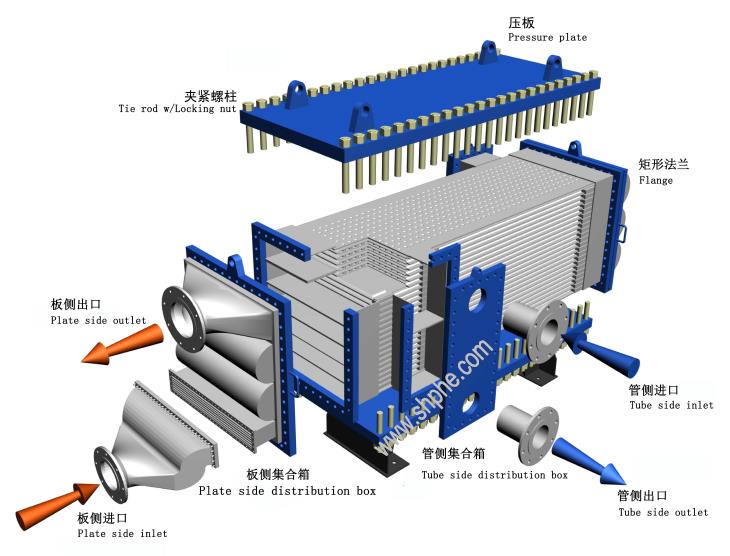

How it works?

The plate heat exchanger can be especially used for thermal treatment such as heat-up and cool-down of viscous medium or medium contains coarse particles and fiber suspensions in sugar, papermaking, metallurgy, ethanol and chemical industries.

Special design of the heat exchange plate ensures better heat transfer efficiency and pressure loss than other kinds of heat exchange equipment in the same condition. Smooth flow of the fluid in the wide gap channel is also ensured. It realizes the aim of no“ dead area” and no deposition or blockage of the coarse particles or suspensions.

The channel at one side is formed between flat plate and flat plate that welded together with stud. The channel at the other side is formed between flat plates with wide gap, and no contact point. Both channels are suitable for high viscous medium or medium containing coarse particles and fiber.

Application

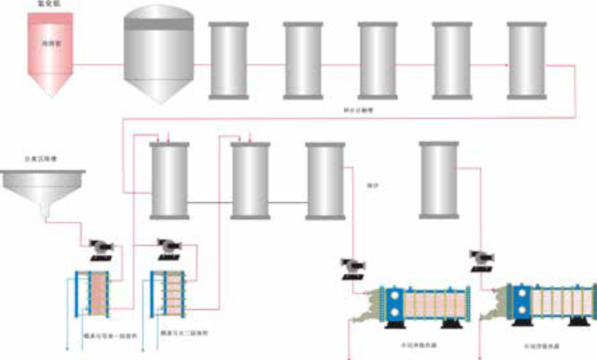

Alumina, mainly sand alumina, is raw material for alumina electrolysis. The production process of alumina can be classified as Bayer-sintering combination. The application of plate heat exchanger in alumina industry successfully reduces erosion and blockage, which in turn increased heat exchanger efficiency as well as production efficiency.

Plate heat exchangers are applied as PGL cooling, agglomeration cooling and interstage cooling.

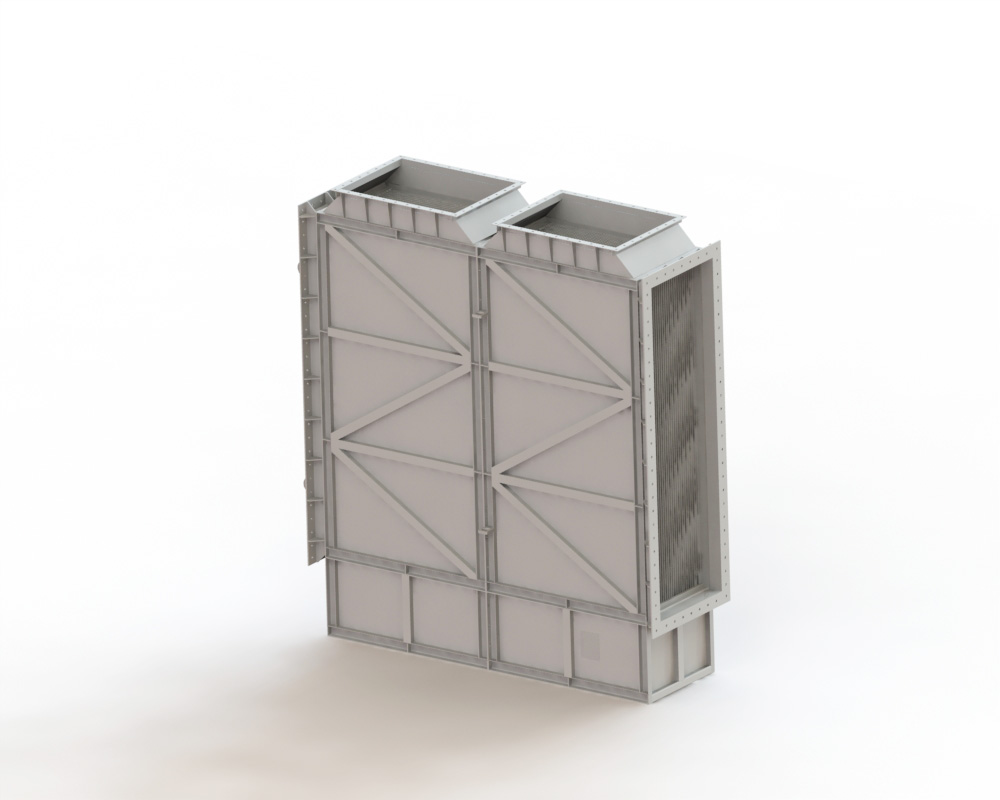

The heat exchanger is applied in the middle temperature drop workshop section in the decomposition and grading work order in the production process of alumina, which is installed on the top or bottom of decomposition tank and used for reducing the temperature of aluminum hydroxide slurry in the decomposition process.

Interstage cooler in Alumina refinery

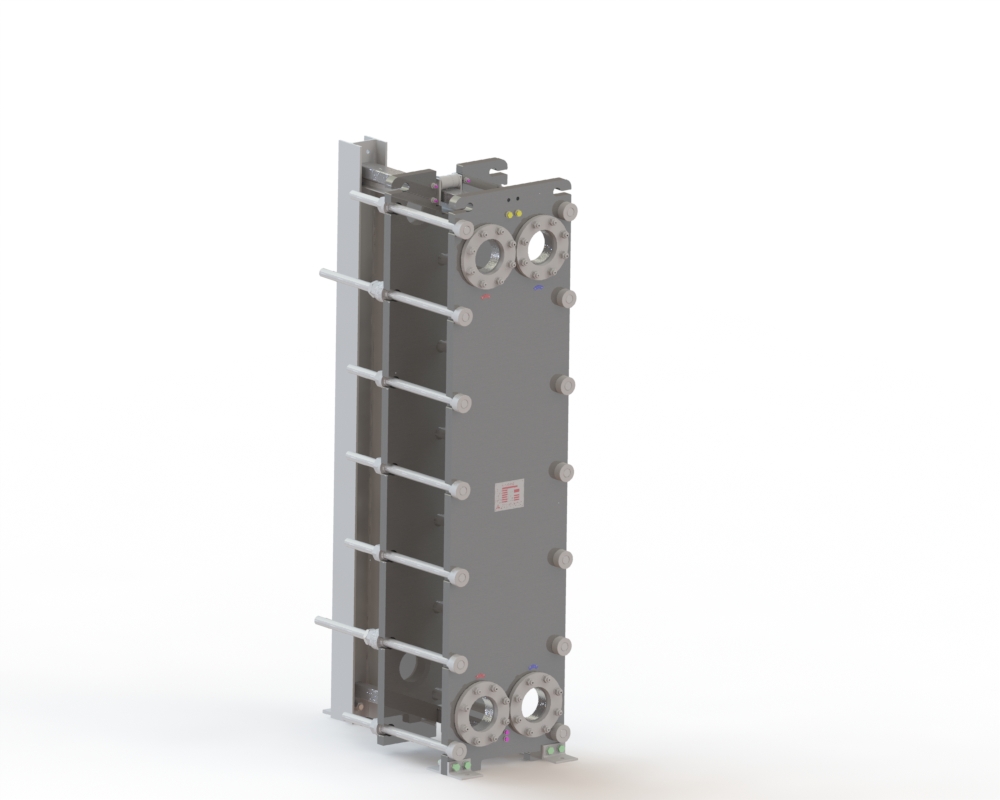

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Hot New Products Heat Exchanger Supplier - Wide Gap Welded Plate Heat Exchanger for Alumina refinery – Shphe , The product will supply to all over the world, such as: Finland , Germany , Bahrain , Our company has always insisted on the business principle of Quality, Honest, and Customer First by which we have won the trust of clients both from at home and abroad. If you are interested in our solutions, you should do not hesitate to contact us for further information.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.