2019 wholesale price Heat Transfer Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in ethanol industry – Shphe

2019 wholesale price Heat Transfer Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in ethanol industry – Shphe Detail:

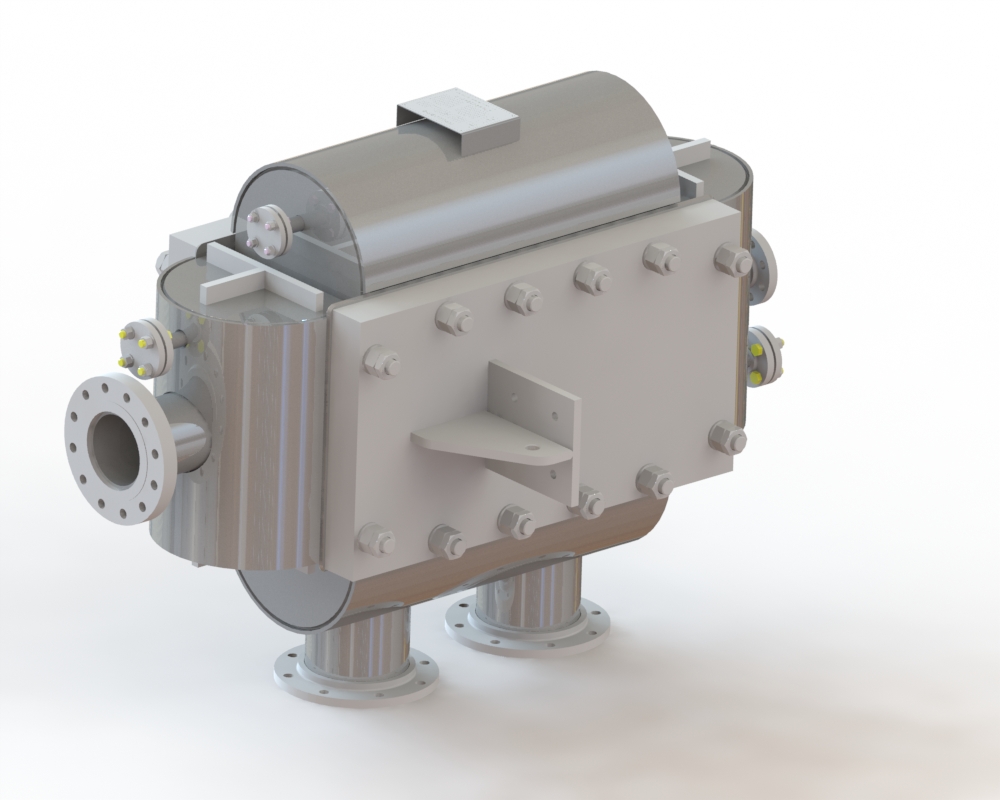

How it works

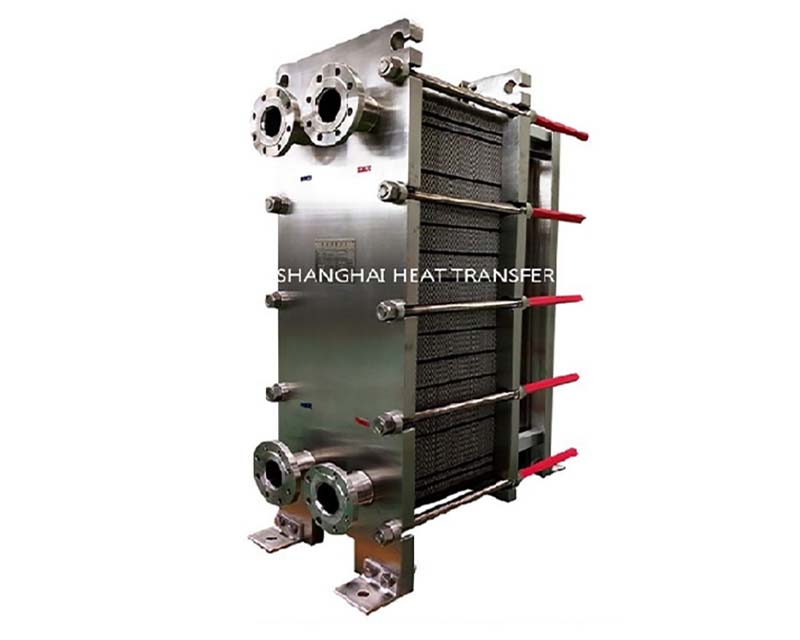

☆ Two plate patterns available for wide-gap welded plate heat exchanger, ie.

☆ dimple pattern and studded flat pattern.

☆ Flow channel is formed between plates which are welded together.

☆ Thanks for the unique design of wide gap heat exchanger, it keeps the advantage of high heat transfer efficiency and low pressure drop over other type of exchangers at the same process.

☆ Moreover, Special design of the heat exchange plate ensures smooth flow of the fluid in the wide gap path.

☆ No “dead area”, no deposition or blockage of the solid particles or suspensions, it keeps the fluid go through the exchanger smoothly without clogging.

Application

☆ The wide gap welded plate heat exchangers are used for the slurry heating or cooling which contain solids or fibers, eg.

☆ sugar plant, pulp & paper, metallurgy, ethanol, oil & gas, chemical industries.

Such as:

● Slurry cooler,Quench water cooler,Oil cooler

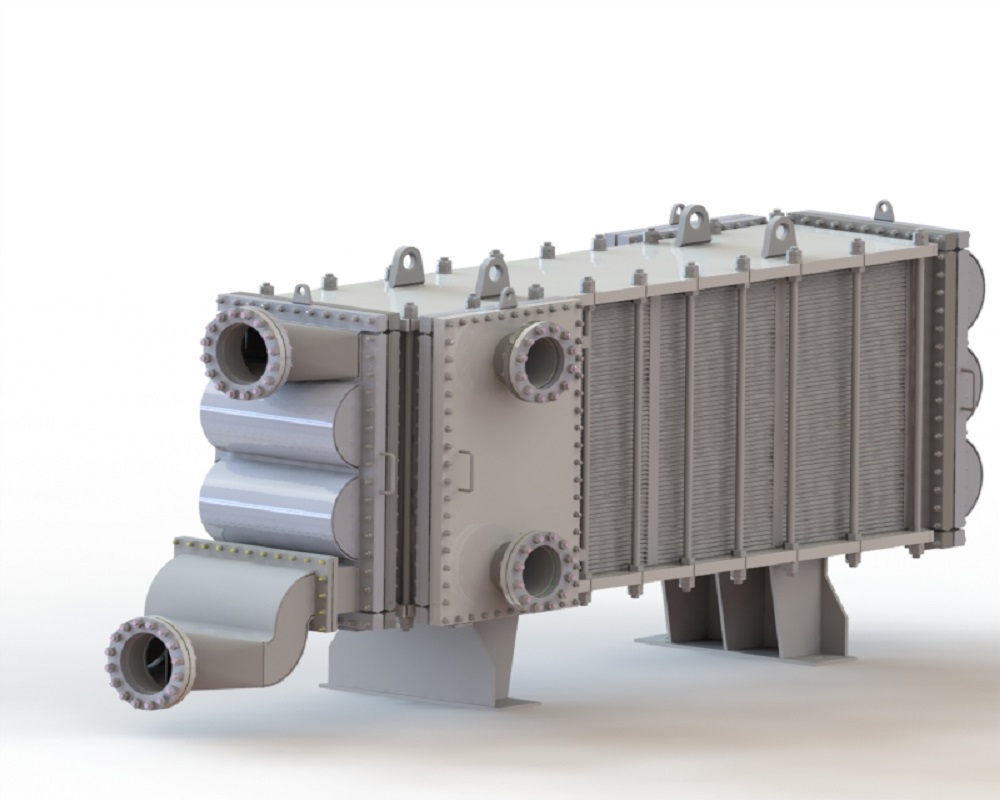

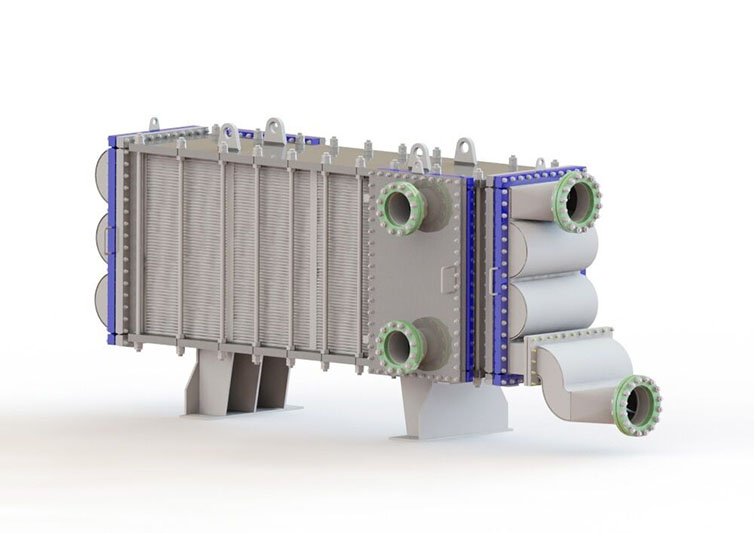

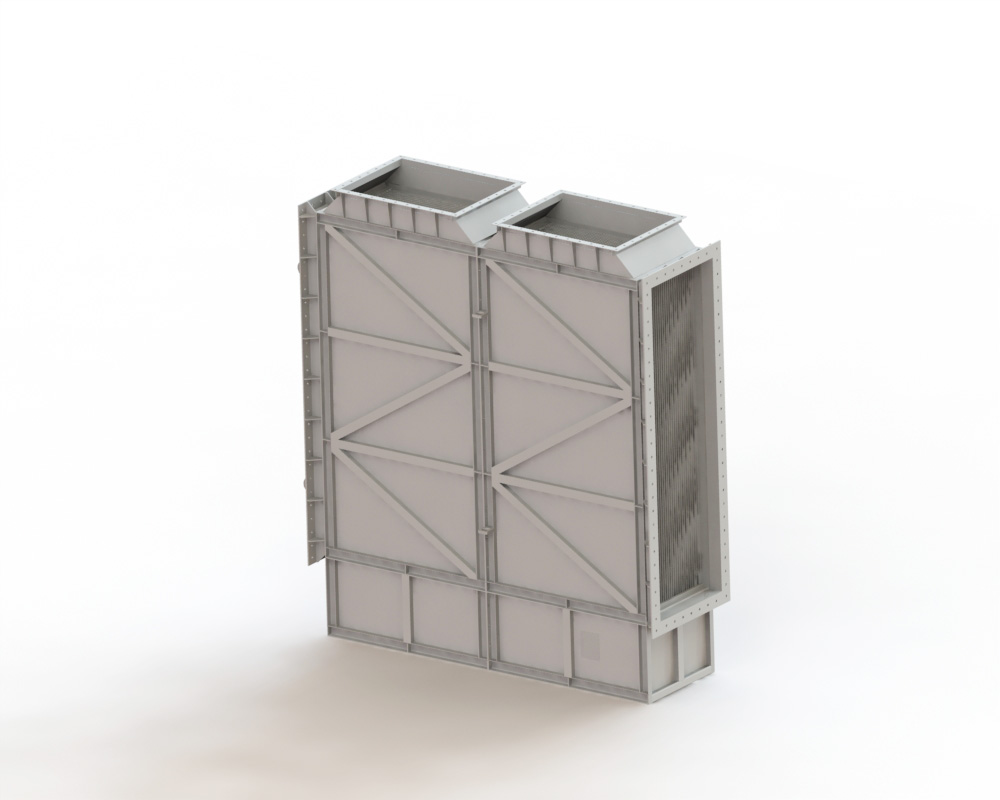

Structure of plate pack

☆ The channel at one side is formed by spot-welded contact points that between dimple-corrugated plates. Cleaner medium runs in this channel. The channel at the other side is wide gap channel formed between dimple-corrugated plates with no contact points, and high viscous medium or medium containing coarse particles runs in this channel.

☆ The channel at one side is formed by spot-welded contact points that are connected between dimple-corrugated plate and flat plate. Cleaner medium runs in this channel. The channel at the other side is formed between dimple-corrugated plate and flat plate with wide gap and no contact point. The medium containing coarse particles or high viscous medium runs in this channel.

☆ The channel at one side is formed between flat plate and flat plate that welded together with studs. The channel at the other side is formed between flat plates with wide gap, no contact point. Both channels are suitable for high viscous medium or medium containing coarse particles and fiber.

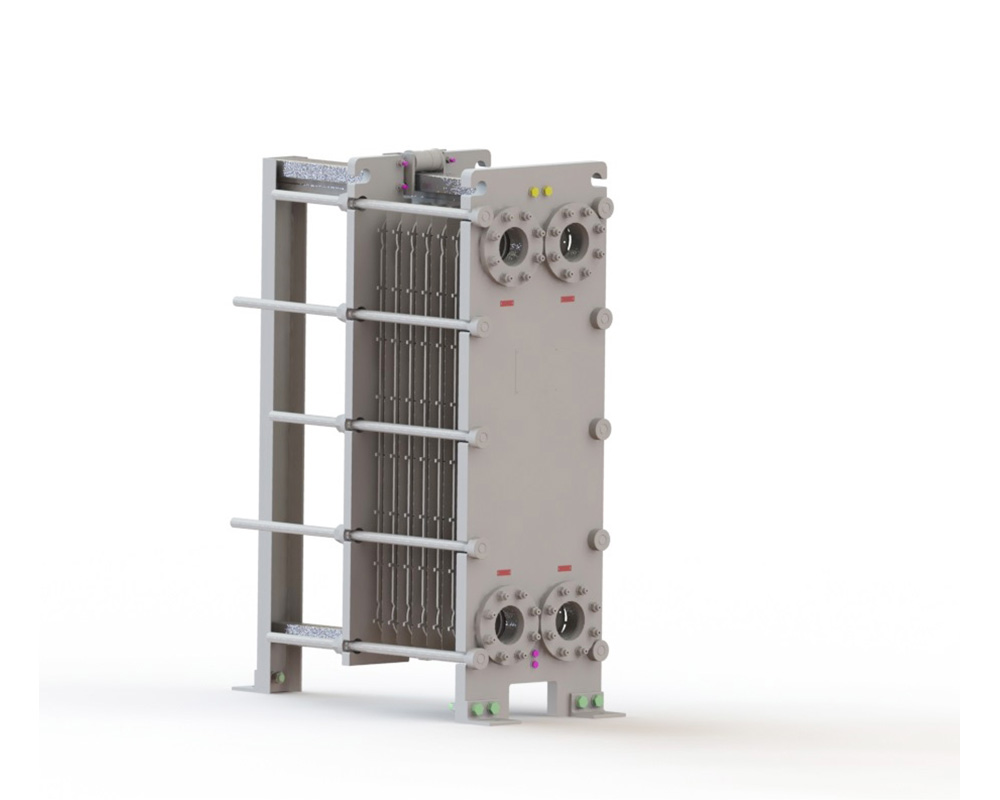

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science plus the theory of quality the basic, have faith in the main and management the advanced for 2019 wholesale price Heat Transfer Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in ethanol industry – Shphe , The product will supply to all over the world, such as: Nigeria , Ghana , Lithuania , Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.