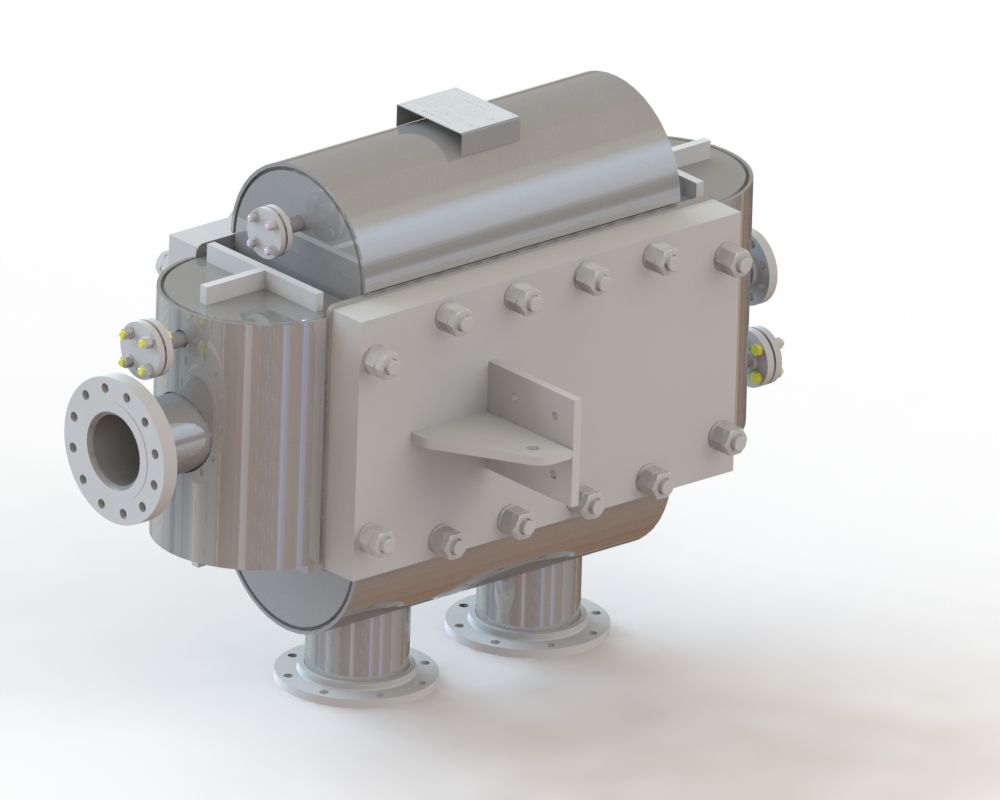

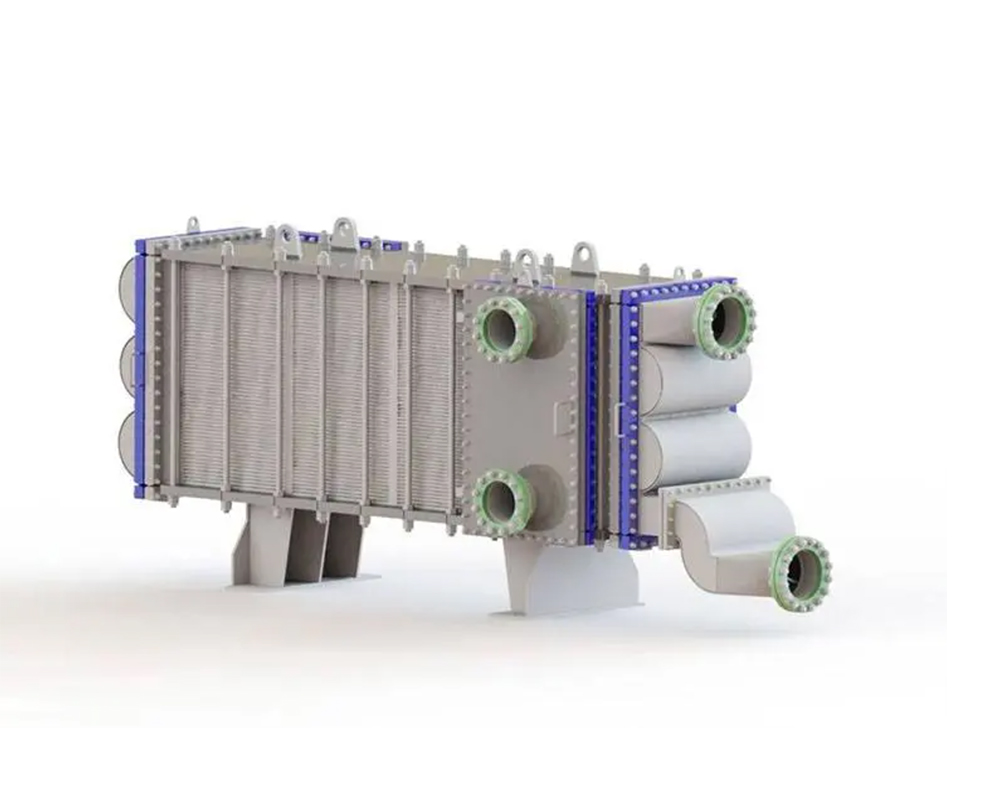

Renewable Design for Chilled Water Plate Heat Exchanger - Plate Heat Exchanger with studded nozzle – Shphe

Renewable Design for Chilled Water Plate Heat Exchanger - Plate Heat Exchanger with studded nozzle – Shphe Detail:

How Plate Heat Exchanger works?

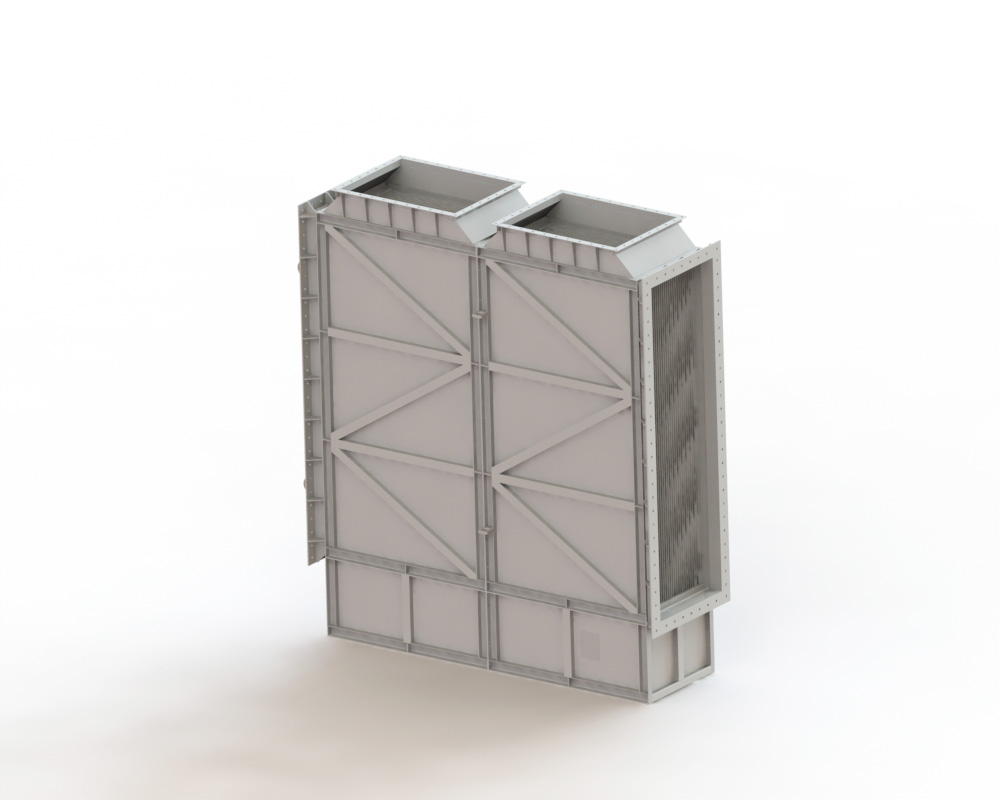

Plate Type Air Preheater

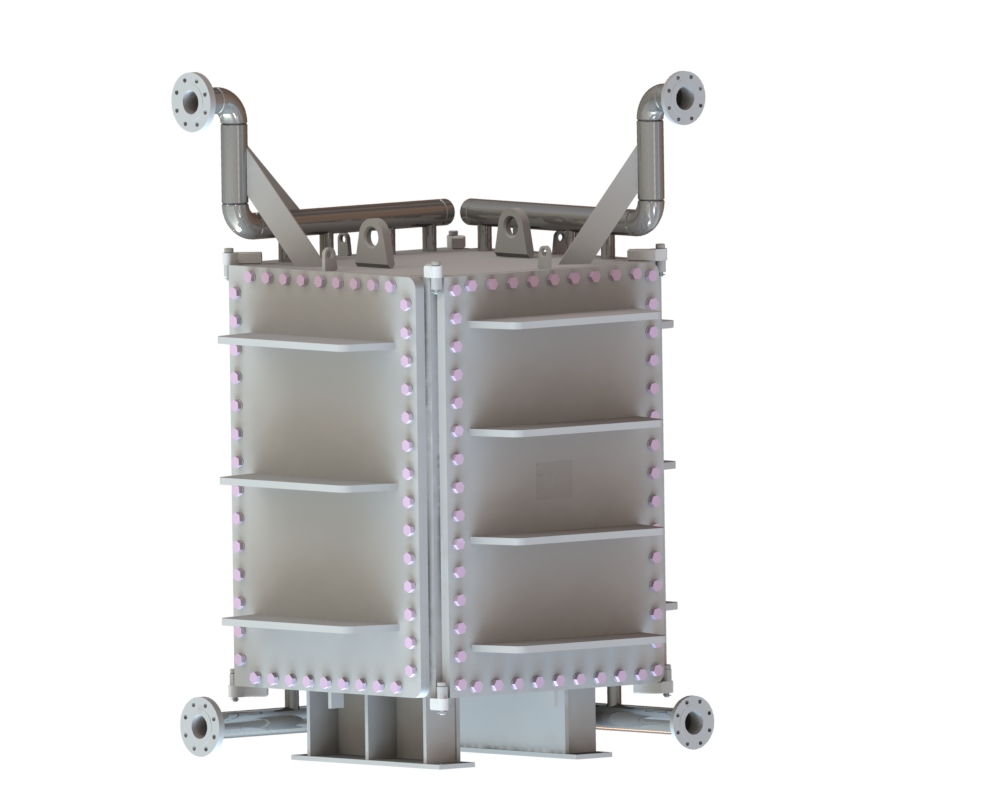

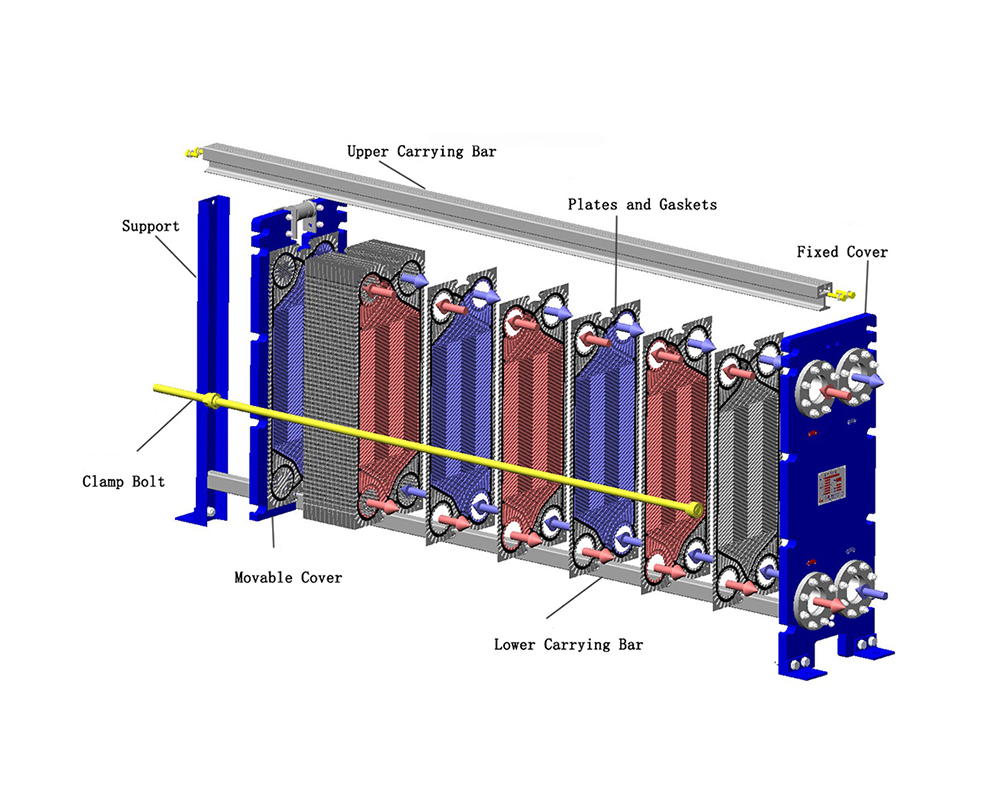

Plate Heat Exchanger is composed of many heat exchange plates which are sealed by gaskets and tightened together by tie rods with locking nuts between frame plate. The medium runs into the path from the inlet and is distributed into flow channels between heat exchange plates. The two fluids flow countercurrent in the channel, the hot fluid transfers heat to the plate, and the plate transfers heat to the cold fluid on the other side. Therefore the hot fluid is cooled down and the cold fluid is warmed up.

Why plate heat exchanger?

☆ High heat transfer coefficient

☆ Compact structure less foot print

☆ Convenient for maintenance and cleaning

☆ Low fouling factor

☆ Small end-approach temperature

☆ Light weight

☆ Small footprint

☆ Easy to change surface area

Parameters

| Plate thickness | 0.4~1.0mm |

| Max. design pressure | 3.6MPa |

| Max. design temp. | 210ºC |

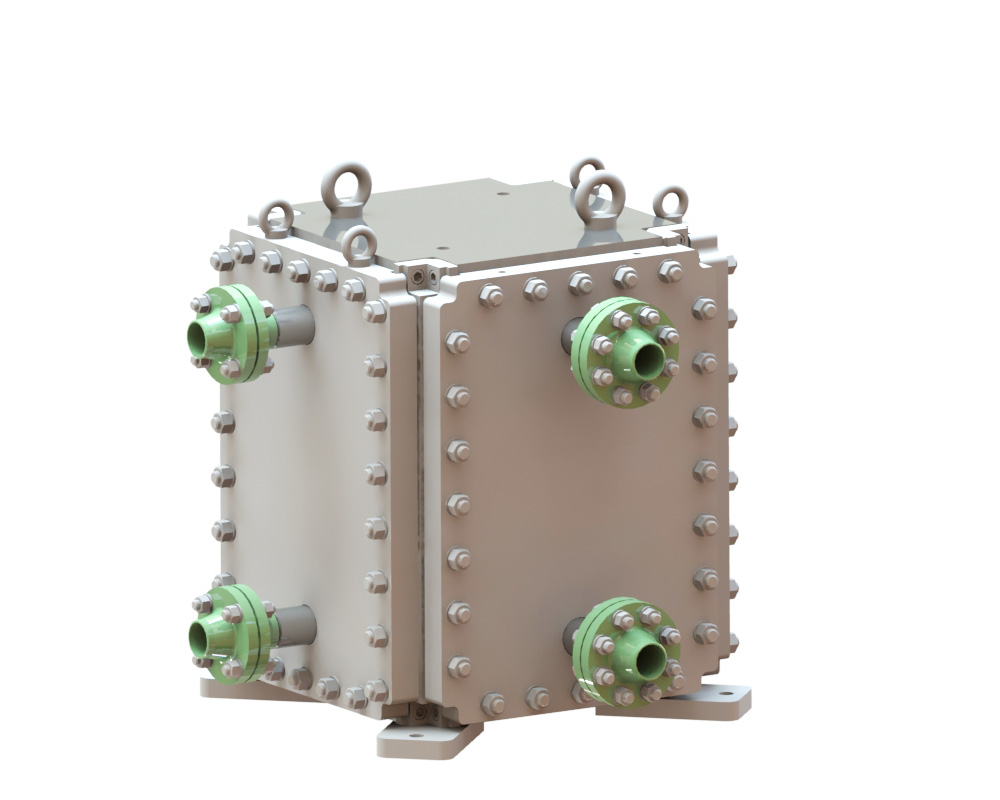

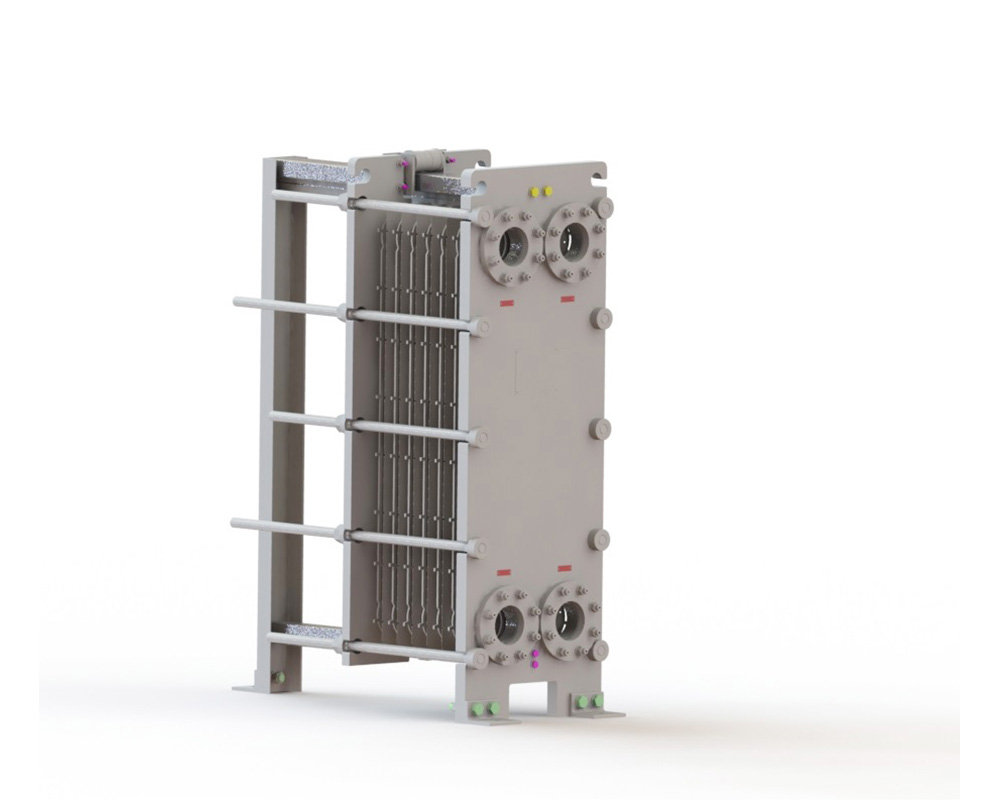

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

We emphasize progress and introduce new merchandise into the market each and every year for Renewable Design for Chilled Water Plate Heat Exchanger - Plate Heat Exchanger with studded nozzle – Shphe , The product will supply to all over the world, such as: Finland, Slovenia, Birmingham, We aspire to meet the demands of our customers globally. Our range of products and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.