Emkhakheni wokuguqulwa kwamandla okushisa kwezimboni,ama-plate heat exchangers ashiselwe ngokugcwele sezibe yimishini eyinhloko yamabhizinisi amaningi ukuze afinyelele ekudlulisweni kokushisa okuphumelelayo nokonga amandla, ngenxa yezinzuzo zawo zokusebenza ezivelele. Kodwa-ke, ukufakwa kwesayensi nokujwayelekile kuyimfuneko yawo ukuze asebenzise ukusebenza kwawo okuhle kakhulu. Umhlahlandlela olandelayo onemininingwane wesinyathelo ngesinyathelo uzokusiza ukulawula ngokunembile inqubo yokufaka, ukhulule ngokugcwele amandla okushintshanisa ukushisa kwamapuleti ashiselwe ngokugcwele, futhi ufake umfutho onamandla ekukhiqizweni nasekusebenzeni kwamabhizinisi.

Ukuqonda Okujulile Ngezinzuzo Eziyingqayizivele Zama-Full Welded Plate Heat Exchangers

Izinzuzo zesakhiwo kanye nokusebenza kwama-plate heat exchanger ahlanganiswe ngokugcwele kuyisihluthulelo sokusebenza kwawo okuvelele ezimweni zokusebenza eziyinkimbinkimbi. Isakhiwo sawo esihlanganisiwe ngokugcwele siyayeka ama-gasket enjoloba endabuko futhi sifinyelele ekuvalekeni ngobuchwepheshe obuqondile bokugoqa ama-plate. Lo mklamo unikeza imishini ukusebenza okuhle kakhulu kokusebenza okuzinzile kwesikhathi eside ngaphandle kokuvuza ezindaweni ezishisa kakhulu nezinomfutho ophezulu. Umklamo wesiteshi esibanzi uyinto evelele kakhulu, efaneleke kakhulu ekuphatheni imidiya eyinkimbinkimbi equkethe izinhlayiya eziqinile, ukungcola kwefayibha, kanye ne-viscosity ephezulu, okunciphisa kakhulu ingozi yokuvaleka nokukala, kanye nokunciphisa imvamisa yokugcinwa kwemishini.

Ngokuphathelene nokusebenza kahle kokudlulisa ukushisa, isakhiwo esihlanganisiwe esilungiselelwe kahle singakha ukugeleza okunamandla okuguquguqukayo ngesikhathi senqubo yokugeleza koketshezi, okuthuthukisa kakhulu umphumela wokushintshana kokushisa. Uma kuqhathaniswa nemishini yegobolondo ne-tube, ukusebenza kahle kokudlulisa ukushisa kukhushulwa ngaphezu kuka-20%, okusindisa inani elikhulu lezindleko zamandla ezinkampanini. Ngokuphathelene nokukhethwa kwezinto, ihlanganisa izinto ezahlukahlukene ezingagqwali kakhulu njengensimbi engagqwali, i-titanium alloy, i-nickel-based alloy, kanye ne-254SMO. Kungakhathaliseki ukuthi kusezimweni zokusebenza ezine-acidic kakhulu noma ezine-alkaline kakhulu, ingalinganiswa ngokunembile ukuqinisekisa ukusebenza okuzinzile kwesikhathi eside kwemishini.

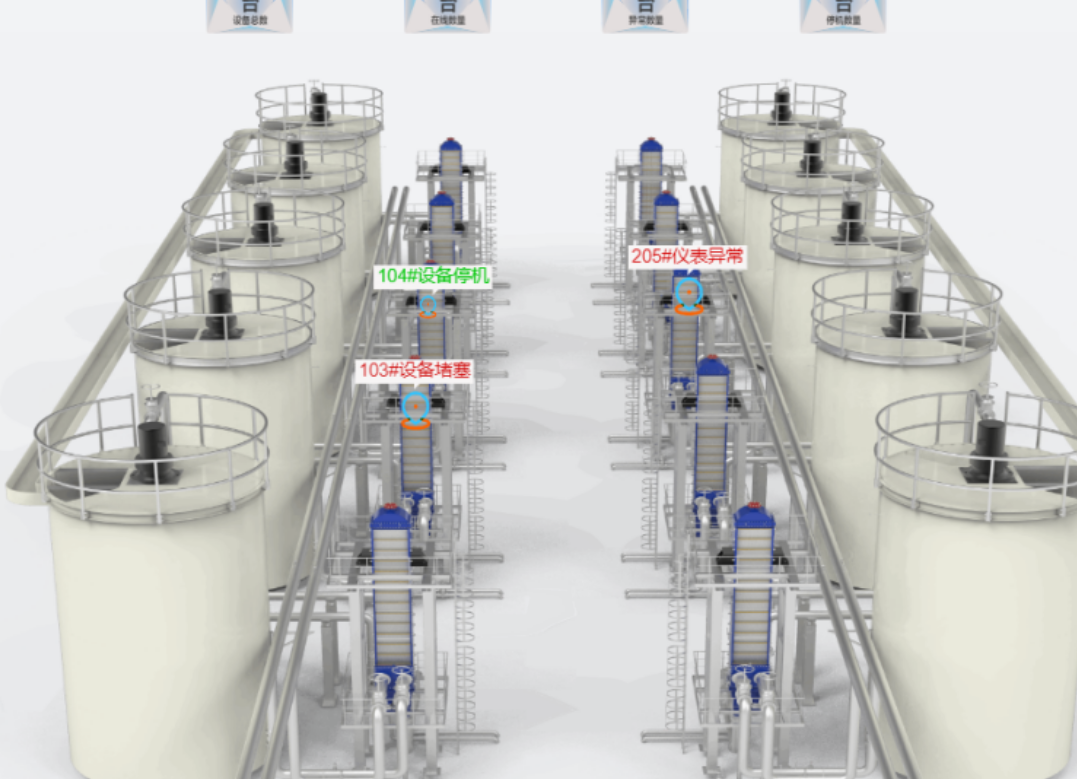

Ngaphezu kwalokho, uhlelo lokuqapha oluhlakaniphile lwe-“Smart Eye ™” oluhlonyiswe ngemishini lungabhekwa “njengobuchopho bedijithali” bemishini, obungakwazi ukuqapha amapharamitha abalulekile ngesikhathi sangempela njengokwehla kwezinga lokushisa kanye nokucindezela. Ngama-algorithms ahlakaniphile, lungafinyelela isixwayiso sokuqala ngokuzenzakalela kanye nokwenza ngcono ukusebenza kahle kwamandla, kugcinwe isimo sokusebenza kwemishini silawulwa futhi kuhambisane nokukhiqizwa okuphephile kanye nokusebenza kahle.

Incazelo yesinyathelo ngesinyathelo yokufakwa kwama-Fully Welded Plate Heat Exchangers

Ukulungiselela Kwangaphambi KokuqalaUkubeka Isisekelo Esiqinile Sokufakwa

- Ukuhlola Indawo Nokuhlela: Ngaphambi kokufaka, kufanele kwenziwe ucwaningo oluphelele lwendawo ukuqinisekisa ukuthi kunesikhala esanele sokufaka futhi sihlangabezana nezidingo zobukhulu bemishini. Indawo kufanele ibe nezimo ezinhle zokungenisa umoya, ibe kude nezindawo zegesi ezishisa kakhulu, ezinomswakama, nezingcolisayo, futhi igweme ukuphazamiseka okuvela emithonjeni yokudlidliza. Ngesikhathi esifanayo, hlela indawo yokusebenza kanye nokufinyelela kokulungisa okuzungeze imishini ukuze kube lula ukugcinwa nokulungiswa kamuva.

Ukuhlolwa Kwemishini kanye Nohlu Lwempahla: Ngemva kokufika kwemishini, hlola ngokucophelela uhlu lokupakisha ukuqinisekisa ukuthi zonke izingxenye zemishini ziphelele futhi akukho monakalo noma ukuguquka kokubukeka. Gxila ekuhloleni ikhwalithi yokushisela yamapuleti, bese uhlola ukuthi ama-weld afana futhi ayaqhubeka yini, nokuthi ngabe kukhona yini amaphutha njengemifantu nemifantu. Uma kukhona noma yikuphi ukukhubazeka, xhumana nomhlinzeki ngesikhathi esifanele ukuze ubhekane nakho ukuqinisekisa ukuthi ikhwalithi yemishini ihlangabezana nezindinganiso.

Ukulungiselela Amathuluzi NokuqukethweLungisa zonke izinhlobo zamathuluzi adingekayo ukuze kufakwe, njengeziphanyeko, imishini yokuphakamisa, kanye namazinga. Ngesikhathi esifanayo, ngokwezidingo zokufaka, lungisa izinto ezisizayo njenge-sealant nama-gasket ukuqinisekisa ukuthi ikhwalithi yezinto ezibonakalayo ihlangabezana nezidingo zokusebenza kwemishini.

Ukubeka Imishini Nokufakwa Kwesisekelo

Indawo Enembile: Nquma indawo eqondile yokufaka imishini endaweni yokufaka ngokwemidwebo yomklamo kanye nokugeleza kwenqubo. Sebenzisa amathuluzi anjengezinga ukuqinisekisa ukuthi iphutha lokulingana kwendiza yokufaka imishini lingaphakathi kobubanzi obubekiwe ukuze ugweme ukugeleza koketshezi okungalingani okubangelwa ukuthambekela kokufakwa, okuthinta umphumela wokushintshana kokushisa.

Ukwakhiwa Kwesisekelo: Isisekelo semishini kufanele sibe namandla anele kanye nokuqina ukuze sikwazi ukumelana nesisindo kanye nokudlidliza kwemishini ngesikhathi sokusebenza. Ubuso besisekelo kufanele bube bushelelezi futhi bube bushelelezi. Uma ufaka amabhawodi e-anchor noma ufaka isisekelo, lawula ngokuqinile indawo yawo kanye nokuphakama kwawo ukuqinisekisa ukuhambisana okunembile nezimbobo zokufaka imishini. Ngemva kokuba ukwakhiwa kwesisekelo sekuqediwe, yenza ukupholisa, futhi imishini ingafakwa kuphela ngemva kokuba amandla efinyelele izidingo.

Ukuphakamisa Nokubeka Imishini

Ukwakhiwa Kohlelo Lokuphakamisa: Ngokuya ngesisindo, ubukhulu bemishini, kanye nezimo zendawo yokufaka, yakha uhlelo lokuphakamisa olungokwesayensi nolunengqondo. Khetha imishini yokuphakamisa efanele kanye namathuluzi okuphakamisa ukuqinisekisa ukuphepha nokuthembeka kwenqubo yokuphakamisa. Ngesikhathi sokuphakamisa, gwema ukushayisana kanye nokukhishwa kwemishini, futhi uvikele ubuso kanye nezingxenye zokushisela zemishini.

Ukubeka Okubushelelezi: Ngesikhathi senqubo yokuphakamisa nokubeka imishini, lungisa kancane indawo yayo ukuze iwele ngokunembile kuma-bolts e-base anchor noma isisekelo. Sebenzisa ileveli ukuthola ukuhleleka kwemishini futhi. Uma kukhona ukuphambuka, yenza ukulungisa okuncane ngokulungisa ama-gasket nezinye izindlela ukuqinisekisa ukuthi imishini ifakwe ngokuvundlile nangokuqinile.

Ukwelashwa Kokuxhumeka Nokuvalwa Kwepayipi

Ukufakwa Kwepayipi: Faka amapayipi ngokwezidingo zomklamo ukuqinisekisa ukuthi imizila yamapayipi ifanelekile futhi ukwakheka kwawo kucocekile. Uma uxhuma amapayipi emishinini, gwema ukuhambisana okuphoqelekile ukuvimbela ukucindezeleka kwamapayipi ukuthi kungadluliselwa emishinini, okuthinta ukusebenza okuphephile kwemishini. Kumapayipi okushisa okuphezulu kanye nokucindezela okuphezulu, kufanele kubekwe amadivayisi okubuyisela adingekayo ukuze amunce ukufuduka okubangelwa ukwanda nokuncipha kokushisa kwamapayipi.

Ukwelashwa Kokuvala: Ukuvalwa kokuxhumana phakathi kwepayipi kanye nemishini kubaluleke kakhulu. Sebenzisa i-sealant noma ama-gasket asezingeni eliphezulu bese uwafaka ngokwenqubo yokuvala echaziwe. I-sealant kufanele isetshenziswe ngokulinganayo nangenani elifanele, futhi ama-gasket kufanele afakwe acwebezelisiwe futhi angenamibimbi. Qinisa amabhawodi okuxhuma ngokulinganayo ukuqinisekisa umphumela wokuvala futhi uvimbele ukuvuza okuphakathi.

Ukufakwa kukagesi kanye nezinsimbi

Ukuxhumeka Kukagesi: Ngokwemidwebo kagesi yemishini, xhuma izintambo zikagesi, izintambo zokulawula, kanye neminye imigqa kagesi. Qinisekisa ukuthi ukuxhumana kukagesi kuqinile nokuthi izintambo zikagesi zilungile, nokuthi ukufakwa kwezintambo zikagesi kuhambisana nemigomo efanele. Ngemva kokuthi ukufakwa sekuqediwe, lungisa iphutha ohlelweni lukagesi ukuze uhlole ukuthi ukusebenza kukagesi kwemishini kujwayelekile yini.

Ukufakwa Kwezinsimbi: Faka amathuluzi okuqapha afana nokushisa, ingcindezi, kanye nesivinini sokugeleza ukuqinisekisa ukuthi izindawo zokufaka amathuluzi zifanelekile futhi kulula ukuzibona nokuzinakekela. Ukuxhumeka kwamathuluzi kufanele kube okunembile futhi kungabi namaphutha, futhi ukudluliswa kwesiginali kufanele kuzinzile. Ngemva kokuthi ukufakwa sekuqediwe, lungisa bese ulungisa amathuluzi ukuqinisekisa ukuthi idatha yokulinganisa inembile futhi ithembekile.

Ukulungisa Amaphutha Nokwamukelwa Kwesistimu

Ukulungisa Amaphutha Komshini Owodwa: Ngemva kokuthi ukufakwa kwemishini sekuqediwe, yenza ukulungisa amaphutha ngomshini owodwa. Qala imishini bese uhlola ukuthi imishini isebenza kahle yini nokuthi ngabe kukhona imisindo noma ukudlidliza okungajwayelekile. Qapha amapharamitha okusebenza kwemishini, njengokushisa, ingcindezi, kanye nesivinini sokugeleza, ukuqinisekisa ukuthi wonke amapharamitha ahlangabezana nezidingo zomklamo. Uma kukhona ukukhubazeka, misa umshini ngesikhathi ukuze uxazulule amaphutha kuze kube yilapho imishini isebenza ngendlela evamile.

Ukulungisa Amaphutha Ngokuhlangana: Ngokusekelwe ekulungiseni amaphutha komshini owodwa okufanelekile, yenza ukulungisa amaphutha okuhlangana kohlelo. Lingisa izimo zokusebenza zokukhiqiza zangempela bese usebenzisa lonke uhlelo ukuhlola izimo zokusebenza ezisebenzisanayo phakathi kwemishini neminye imishini yohlelo. Qaphela ukuzinza kokusebenza kohlelo bese uthola ukuthi ukusebenza kahle kokushintshana kokushisa kufinyelela yini kunkomba yokuklama. Lungisa izinkinga ezitholakale ngesikhathi senqubo yokulungisa amaphutha ngesikhathi esifanele ukuqinisekisa ukusebenza okuthembekile kohlelo.

Ukwamukelwa Nokulethwa: Ngemva kokuthi ukulungisa amaphutha sekuqediwe, hlela abasebenzi abafanele ukwamukela imishini. Yenza ukuhlolwa okuphelele nokuhlolwa kwekhwalithi yokufaka imishini, ukusebenza kahle kwayo, ukuvikelwa kokuphepha, nezinye izici ngokuya ngezindinganiso zokwamukela. Ngemva kokuthi ukwamukelwa sekufanelekile, sayina amadokhumenti okwamukela, bese imishini ilethwa ngokusemthethweni ukuze isetshenziswe.

Izindawo Zokusebenza Nokulungisa Ngemva Kokufakwa

Lawula Ngokuqinile Izimo Zokusebenza

Ukuphathwa Kwezinga Lokushisa: Ngesikhathi sokusebenza, akuvunyelwe ngokuphelele ukuthi izinga lokushisa lemishini lidlule umkhawulo ophezulu womklamo ukuze kugwenywe ukuqhekeka kokukhathala kokushisa kwama-weld okubangelwa izinga lokushisa elidlulele. Qapha ushintsho lokushisa lwemishini ngesikhathi sangempela, setha umkhawulo we-alamu yokushisa ofanele, bese uthatha izinyathelo zokupholisa ngesikhathi lapho izinga lokushisa lingavamile.

Ukulawula Ukucindezela: Qinisekisa ukuthi ingcindezi yokusebenza kwemishini ingaphakathi kwebanga elibekiwe ukuvimbela ukwehluleka kwama-weld ngenxa yengcindezi enkulu. Faka idivayisi yokuqapha ingcindezi ukuze uqaphe ingcindezi ngesikhathi sangempela. Uma ingcindezi ishintshashintsha ngendlela engajwayelekile, phenya ngokushesha imbangela bese wenza izinguquko.

Ukulawula Umehluko Wezinga Lokushisa: Nciphisa umehluko wokushisa phakathi kwemidiya eshisayo nebandayo ukuze ugweme ukukhathala kwama-plate welds okubangelwa ukucindezeleka okukhulu kokushisa. Ngesikhathi senqubo yokuqalisa nokuvala imishini, lawula ngokufanele izinga lokugeleza kanye nezinga lokushintsha kwezinga lokushisa lemidiya eshisayo nebandayo ukuze ufinyelele ushintsho olubushelelezi.

Qinisa Ukuphathwa Kwemithombo Yezindaba Emanzi

Ukulawulwa Kwezinto Ezonakalisayo: Kuma-media agqwalisayo, hlola njalo inani lawo le-pH ukuqinisekisa ukuthi izici zama-media zihambisana nezinto zokushisela zemishini. Isibonelo, ezimweni zokusebenza ezine-chlorine ephezulu, khetha imishini eyenziwe ngezinto ze-C – 276. Ngokuya ngokugqwala kwama-media, dala izindlela ezifanele zokulwa nokugqwala ukuze wandise impilo yemishini.

Ukwelashwa Kokungcola Kwezinhlayiya: Uma uphatha imidiya enokuqukethwe okuphezulu kokungcola, kufanele kufakwe isihlungi, futhi ukunemba kokuhlunga kufanele kuhlangabezane nezidingo zokusebenza kwemishini. Ngesikhathi esifanayo, ngokwezici zemidiya, khetha imishini enesiteshi esibanzi ukuze unciphise ingozi yokuvaleka. Hlanza isihlungi njalo ukuze uvimbele ukusebenza okuvamile kwemishini ukuthi kungathinteki ngenxa yokuvaleka kwesihlungi.

Imininingwane Yokuhlanza: Akuvunyelwe ngokuphelele ukusebenzisa izinto zokuhlanza eziqukethe i-chloric acid ukuhlanza imishini. Ukuhlanza okungalungile kuzoholela ekuqhekekeni nasekubhobozeni kwezinsimbi. Yakha uhlelo lokuhlanza lwesayensi, bese ukhetha izindlela ezifanele zokuhlanza, ukuhlanza nge-alkali, noma ukuhlanza ngokomzimba ngokwezici zemidiya kanye nezimo zokusebenza kwemishini. Umjikelezo wokuhlanza unconywa ukuthi ube kanye ngonyaka noma njalo ezinyangeni eziyi-6 - 12 zokusebenza. Ngemva kokuhlanza, thola ngokushesha ukucindezela, izinga lokugeleza, kanye nokusebenza kahle kokushintshana kokushisa kwemishini ukuqinisekisa ukuthi ukusebenza kwemishini kubuyela esimweni esijwayelekile.

Hlanganisa Ukusebenza Nokunakekelwa Okuhlakaniphile Nokunakekelwa Kwansuku Zonke

Nika amandla uhlelo lokuqapha oluhlakaniphile: Nikeza indima ye-“Smart Eye” ukudlala ngokugcwele™"Uhlelo lokuqapha oluhlakaniphile ukuze kufezwe ukuqapha kwangempela kwesimo sezulu kanye nokuxwayisa kusenesikhathi ngamapharamitha afana nokushisa, ukwehla kwengcindezi, kanye nokusebenza kahle kwemishini. Ngokuhlaziya idatha yesistimu, thola ngokushesha amaphutha angaba khona kanye nezinkinga zokuwohloka kokusebenza kwemishini, thola ngokushesha izindawo zamaphutha, futhi unikeze isiqondiso esikude sokulungisa ukuze kuthuthukiswe ukusebenza kahle komshini.

Ukuhlolwa Kwansuku Zonke Nokulungiswa: Misa uhlelo lokuhlola nsuku zonke lwemishini, futhi uhlole njalo isimo sokusebenza kwemishini, okuhlanganisa ukubukeka kwemishini, izingxenye zokuxhuma, kanye nokufundwa kwemishini. Hlola ukuthi ngabe kukhona yini izimo ezingavamile njengokuvuza, umsindo ongavamile, nokudlidliza emishinini, bese ubhekana nezinkinga ezitholakala ngesikhathi. Hlanza njalo futhi ulondoloze imishini ukuze ugcine ubuso bemishini buhlanzekile futhi uvimbele ukuqongelela kothuli nokungcola kungathinti ukushabalaliswa kokushisa kanye nokusebenza kwemishini.

Izinyathelo Zobuchwepheshe Zokuvimbela Ukwehluleka Kokushisela

Ukulawulwa Kokuguquguquka Kwezinga Lokushisa: Gwema ukushintshashintsha okukhulu kwezinga lokushisa kwemishini ukuze unciphise ukukhathala kokushisa kwendawo yokushisela. Lungiselela inqubo yokukhiqiza, hlela ngokufanele isikhathi sokuqala nokuvala kwemishini, futhi unciphise umthelela wokushintsha kwezinga lokushisa kumashisela.

Ukuqinisekisa Ikhwalithi Yokushisela:Khetha inqubo yokushisela efanelekile bese uyakha ngokuqinile ngokuhambisana nezincazelo zenqubo yokushisela. Yenza ukuhlolwa okungonakalisi (njengokutholwa kwamaphutha e-X-ray) ezingxenyeni zokushisela ukuqinisekisa ukuthi ikhwalithi yokushisela iyahlangabezana nezidingo. Endabeni yoketshezi olubhidlizayo, khetha izintambo zokushisela ezihambisanayo nezinto zokwakha ukuvimbela ukuvela kwemifantu yokugqwala kokucindezeleka.

Ukukhululeka Ekucindezelekeni: Ngesikhathi sokufakwa kwemishini kanye nokuxhumeka kwamapayipi, thatha izinyathelo zokukhulula ukucindezeleka kwemishini kanye namapayipi ukuze ugweme ukulimala kwama-welds okubangelwa ukugcwala kokucindezeleka. Isibonelo, beka ngokufanele izisekelo zamapayipi, ama-compensator, njll. ukuze umunce ukucindezeleka okubangelwa ukwanda nokuncipha kokushisa kwamapayipi.

Yakha Amasu Okwandisa Impilo Yemishini

Ukuphathwa Kwezingxenye Eziyisipele: Dala isu lezingxenye ezisele ezingasasebenzi, bese uhlela ama-plate bundle noma amamojula asele ngokwesimo sokusebenza kwemishini kanye nomjikelezo wokushintsha izingxenye ezisengozini. Qinisekisa ukuthi uma imishini yehluleka, izingxenye ezisele zingashintshwa ngesikhathi esifanele, kuncishiswe isikhathi sokulinda sokungasebenzi futhi kuqinisekiswe ukuqhubeka kokukhiqiza.

Ukuhlela Ukulungisa: Hlela ngokwesayensi umjikelezo wokugcinwa kwemishini. Kunconywa ukwenza ukuhlolwa okuvamile okuphelele kanye ngonyaka, futhi ezinhlelweni ezisebenza kanzima, kufanele kwenziwe ukuhlolwa njalo ezinyangeni eziyisithupha. Yakha uhlelo lokugcinwa olunemininingwane, wenze ukuhlolwa okuphelele, ukulungiswa, kanye nokulungiswa kwemishini, bese uthola ngokushesha futhi ubhekane nezinkinga ezingaba khona ukuze wandise impilo yemishini.

Ukuphathwa Kwemininingwane Yokusebenza:Qinisa ukuqeqeshwa kwabasebenzi ukuze bakwazi ukuqonda izindlela zokulungisa ingcindezi kanye nokushisa kwemishini kanye nekhono lokwahlulela idatha engajwayelekile. Yakha izinqubo eziqinile zokusebenza kwemishini, yenza kube sezingeni elifanayo ukuziphatha kwabasebenzi, futhi ugweme umonakalo wemishini obangelwa ukusebenza okungafanele.

Ukuthuthukiswa Kwemvelo:Qinisa ukuphathwa kwendawo yokufaka imishini, thatha izinyathelo zokunciphisa umthelela wemithombo yokudlidliza emishinini, futhi uqinisekise ukuthi imishini ifakwe kahle. Yenza umsebenzi omuhle ezindleleni zokuvikela umswakama kanye nokulwa nokugqwala, uvikele imishini ezicini zemvelo, futhi udale isimo esihle sokusebenza kwemishini.

Isiphetho

Njengemishini eyinhloko yokudlulisa ukushisa okuphumelelayo emkhakheni wezimboni, ikhwalithi yokufaka kanye nokusebenza kanye nokugcinwa kwama-plate heat exchanger ahlanganiswe ngokuphelele kuhlobene ngqo nokusebenza kahle kwemishini kanye nokusebenza kahle kokukhiqiza kwamabhizinisi. Ngokulandela umhlahlandlela wokufaka wesayensi noqinile ongenhla kanye namaphuzu okusebenza nokulungisa ngokucophelela, ukusebenza okuzinzile nokuphumelelayo kwama-plate heat exchanger ahlanganiswe ngokuphelele ezimweni zokusebenza ezinzima njengokushisa okuphezulu, umfutho ophezulu, ukugqwala okulula, kanye nokuvaleka okulula kungaqinisekiswa, kusize amabhizinisi ukufeza umgomo "wokusebenza okuphephile + ukunciphisa izindleko kanye nokuthuthukisa ukusebenza kahle".

I-Shanghai Heat Transfer Equipment Co., Ltd., njengomhlinzeki ohamba phambili wezixazululo zokushintshanisa ukushisa embonini, enolwazi olucebile kanye nethimba lobuchwepheshe elingochwepheshe, ingakunikeza izixazululo ezenziwe ngokwezifiso zama-plate heat exchanger ashiselwe ngokugcwele kanye nokusekelwa kobuchwepheshe ochwepheshe okuphelele. Kungakhathaliseki ukuthi ukukhetha imishini, isiqondiso sokufaka, ukusebenza nokugcinwa, noma ukuphathwa kwamaphutha, sizokukhonza ngenhliziyo yonke. Uma udinga ulwazi olwengeziwe noma usizo, sicela ukhululeke ukuxhumana nathi.:

I-imeyili:

zhanglimei@shphe.com

qiuying@shphe.com

I-WhatsApp / Ucingo:+86 15201818405

I-WhatsApp / Ucingo: +86 13671925024

Isikhathi sokuthunyelwe: Mashi-25-2025