Kwicandelo lokuguqulwa kwamandla obushushu kwimizi-mveliso,izitshintshi zobushushu zepleyiti ezitshisiweyo ngokupheleleyo ziye zaba zizixhobo eziphambili kumashishini amaninzi ukuze afezekise ukudluliselwa kobushushu ngokufanelekileyo kunye nokugcinwa kwamandla, ngenxa yeenzuzo zawo zokusebenza ezibalaseleyo. Nangona kunjalo, ukufakelwa kwesayensi kunye nomgangatho kuyimfuneko kubo ukuze basebenze kakuhle. Esi sikhokelo silandelayo senyathelo ngenyathelo siya kukunceda ulawule ngokuchanekileyo inkqubo yokufaka, ukhulule ngokupheleleyo amandla ee-plate heat exchangers ezitshixiweyo ngokupheleleyo, kwaye ufake amandla amakhulu kwimveliso kunye nokusebenza kwamashishini.

Ukuqonda Okunzulu Ngeengenelo Ezikhethekileyo Zee-Full Welded Plate Heat Exchangers

Iingenelo zesakhiwo kunye nokusebenza kwezitshintshi zobushushu zepleyiti ezidityaniswe ngokupheleleyo zibalulekile ekusebenzeni kwazo okugqwesileyo kwiimeko zokusebenza ezinzima. Ulwakhiwo lwazo oludityaniswe ngokupheleleyo luyazishiya ii-gasket zerabha zemveli kwaye lufezekisa ukutywinwa ngetekhnoloji echanekileyo yokudityaniswela iipleyiti. Olu yilo lunika izixhobo ukusebenza okuhle kakhulu kokusebenza okuzinzileyo ixesha elide ngaphandle kokuvuza kwiindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu. Uyilo lwe-wide-channel luphawu oluphambili, olufaneleke ngakumbi ekuphatheni imidiya enzima equlethe amasuntswana aqinileyo, ukungcola kwefayibha, kunye ne-viscosity ephezulu, okunciphisa kakhulu umngcipheko wokuvaleka kunye nokukhula, kunye nokunciphisa amaxesha okugcinwa kwezixhobo.

Ngokuphathelele ukusebenza kakuhle kokudlulisa ubushushu, isakhiwo esilungisiweyo se-corrugated sinokwenza ukuhamba okunamandla okuguquguqukayo ngexesha lenkqubo yokuhamba kolwelo, nto leyo ephucula kakhulu isiphumo sokutshintshiselana kobushushu. Xa kuthelekiswa nezixhobo ze-shell-and-tube, ukusebenza kakuhle kokudlulisa ubushushu kunyuswa ngaphezulu kwama-20%, okonga iindleko ezinkulu zamandla kumashishini. Ngokuphathelele ukhetho lwezinto, igubungela iintlobo ngeentlobo zezinto ezimelana nokugqwala kakhulu ezifana nentsimbi engatyiwayo, i-titanium alloy, i-nickel-based alloy, kunye ne-254SMO. Nokuba zikwimeko yokusebenza ene-asidi enamandla okanye ene-alkaline enamandla, inokufaniswa ngokuchanekileyo ukuqinisekisa ukusebenza okuzinzileyo kwexesha elide kwezixhobo.

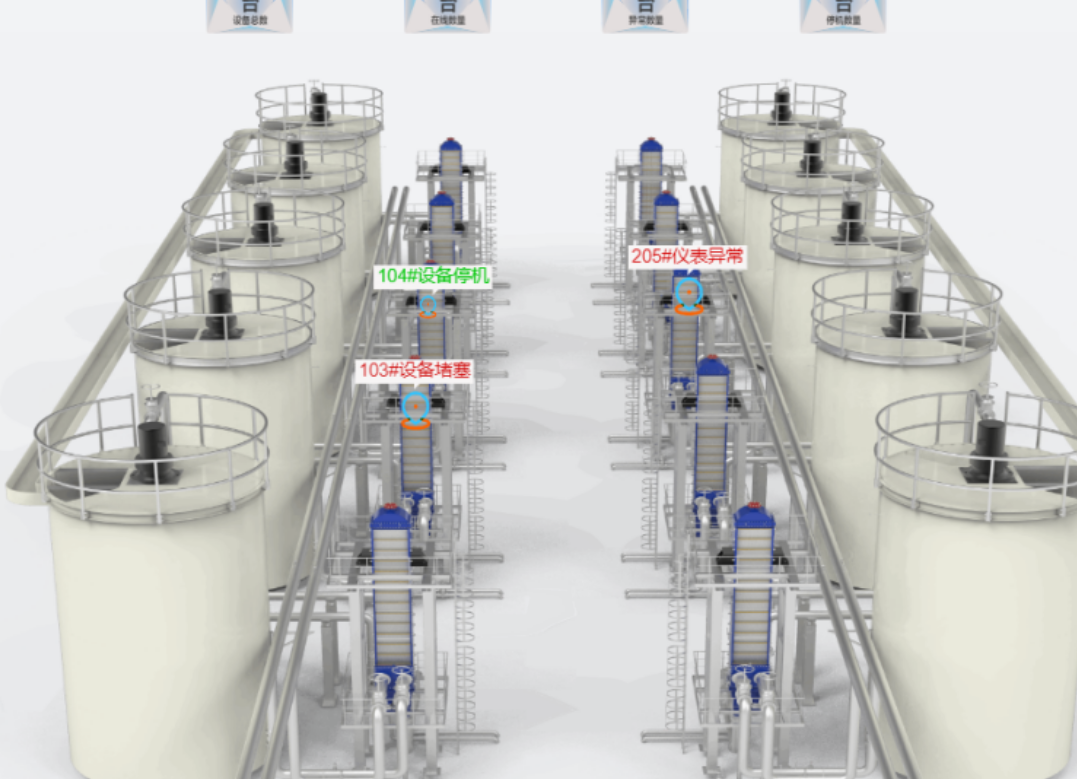

Ukongeza, inkqubo yokujonga ekrelekrele ye-"Smart Eye ™" exhotyiswe ngezixhobo ingathathwa njenge "ingqondo yedijithali" yezixhobo, enokujonga iiparameter eziphambili ngexesha langempela ezifana nobushushu kunye nokuhla koxinzelelo. Ngokusebenzisa ii-algorithms ezikrelekrele, inokufezekisa isilumkiso sangethuba esizenzekelayo kunye nokulungiswa kokusetyenziswa kwamandla, igcine imeko yokusebenza kwezixhobo ilawulwa kwaye ihambise imveliso ekhuselekileyo kunye nokusebenza ngokufanelekileyo.

Inkcazo yenyathelo ngenyathelo yoFakelo lweeFully Welded Plate Heat Exchangers

Ukulungiselela kwangaphambili: Ukubeka Isiseko Esiqinileyo Sokufakelwa

- Uphando lweNdawo kunye nokuCwangcisa: Ngaphambi kokufakwa, kufuneka kwenziwe uphando olupheleleyo lwendawo ukuqinisekisa ukuba kukho indawo eyaneleyo yokufaka kwaye iyahlangabezana neemfuno zobukhulu bezixhobo. Indawo kufuneka ibe neemeko ezilungileyo zokungenisa umoya, ibe kude neendawo zegesi ezinobushushu obuphezulu, ezifumileyo nezirhabaxa, kwaye iphephe ukuphazamiseka okuvela kwimithombo yokungcangcazela. Kwangaxeshanye, cwangcisa indawo yokusebenza kunye nokufikelela kulondolozo olujikeleze izixhobo ukuze kube lula ukugcinwa nokulungiswa kamva.

Ukuhlolwa kwezixhobo kunye noluhlu lwezinto ezisetyenzisiweyo: Emva kokuba izixhobo zifikile, jonga ngononophelo uluhlu lokupakisha ukuqinisekisa ukuba zonke izixhobo zigqityiwe kwaye akukho monakalo okanye ukuguguleka kwimbonakalo. Gxila ekujongeni umgangatho wokuwelda kweepleyiti, kwaye ujonge ukuba iiwelds ziyafana kwaye ziyaqhubeka na, kwaye nokuba kukho iziphene ezifana neembobo kunye nemifantu. Ukuba kukho naziphi na izinto ezingaqhelekanga, nxibelelana nomthengisi ngexesha elifanelekileyo ukuze ujongane nazo ukuqinisekisa ukuba umgangatho wezixhobo uyahlangabezana nemigangatho.

Ukulungiselela Izixhobo kunye nezintoLungisa zonke iintlobo zezixhobo ezifunekayo xa kufakelwa, ezinje ngee-wrenches, izixhobo zokuphakamisa, kunye namanqanaba. Kwangaxeshanye, ngokweemfuno zokufakela, lungiselela izixhobo ezincedisayo ezifana ne-sealant kunye nee-gaskets ukuqinisekisa ukuba umgangatho wezinto uyahlangabezana neemfuno zokusebenza kwezixhobo.

Ukubekwa kwezixhobo kunye nokufakelwa kwesiseko

Indawo Echanekileyo: Chonga indawo echanekileyo yokufaka izixhobo kwindawo yokufakela ngokwemizobo yoyilo kunye nokuhamba kwenkqubo. Sebenzisa izixhobo ezifana nenqanaba ukuqinisekisa ukuba impazamo yokulingana kweplani yokufakela izixhobo ingaphakathi koluhlu oluchaziweyo ukuze uphephe ukuhamba kolwelo okungalinganiyo okubangelwa kukuthambekela kokufakela, okuchaphazela isiphumo sokutshintshiselana kobushushu.

Ukwakhiwa kweSiseko: Isiseko sezixhobo kufuneka sibe namandla aneleyo kunye nozinzo ukuze sikwazi ukumelana nobunzima kunye nokungcangcazela kwezixhobo ngexesha lokusebenza. Umphezulu wesiseko kufuneka ube tyaba kwaye uthambe. Xa ufaka iibholiti ze-anchor okanye ufaka isiseko, lawula ngokungqongqo indawo yazo kunye nokuphakama ukuqinisekisa ukuhambelana ngokuchanekileyo nemingxunya yokufakela izixhobo. Emva kokuba ulwakhiwo lwesiseko lugqityiwe, yenza ukucocwa, kwaye izixhobo zinokufakwa kuphela emva kokuba amandla efikelele kwiimfuno.

UkuPhakamisa kunye nokuBeka Izixhobo

Ukwenziwa kweSicwangciso sokuKhupha: Ngokwesisindo, ubungakanani bezixhobo, kunye neemeko zendawo yokufakela, yenza isicwangciso sokuphakamisa esingokwesayensi nesifanelekileyo. Khetha izixhobo zokuphakamisa ezifanelekileyo kunye nezixhobo zokuphakamisa ukuqinisekisa ukhuseleko kunye nokuthembeka kwenkqubo yokuphakamisa. Ngexesha lokuphakamisa, kuphephe ukungqubana kunye nokukhupha izixhobo, kwaye ukhusele umphezulu kunye neendawo zokuwelda zezixhobo.

Indawo Egudileyo: Ngexesha lenkqubo yokuphakamisa nokubeka izixhobo, lungisa kancinci indawo yezixhobo ukuze ziwele ngokuchanekileyo kwiibholiti zesiseko okanye kwisiseko. Sebenzisa inqanaba ukuze ubone ukulingana kwezixhobo kwakhona. Ukuba kukho ukuphambuka, yenza uhlengahlengiso oluncinci ngokulungelelanisa ii-gaskets kunye nezinye iindlela ukuqinisekisa ukuba izixhobo zifakwe ngokuthe tye nangokuqinileyo.

Uqhagamshelo lweMibhobho kunye noNyango lokutywina

Ukufakwa kweMibhobho: Faka imibhobho ngokweemfuno zoyilo ukuqinisekisa ukuba iindlela zombhobho zifanelekile kwaye uyilo lucocekile. Xa uqhagamshela imibhobho kwizixhobo, kuphephe ukulungelelaniswa okunyanzelekileyo ukuthintela uxinzelelo lombhobho ekudluliselweni kwizixhobo, nto leyo echaphazela ukusebenza ngokukhuselekileyo kwezixhobo. Kwimibhobho enobushushu obuphezulu kunye noxinzelelo oluphezulu, kufuneka kumiselwe izixhobo zokuhlawula ezifunekayo ukuze zifunxe ukufuduka okubangelwa kukwanda kobushushu kunye nokucutheka kwemibhobho.

Unyango lokutywina: Ukuvalwa konxibelelwano phakathi kombhobho kunye nezixhobo kubaluleke kakhulu. Sebenzisa i-sealant okanye ii-gaskets ezikumgangatho ophezulu kwaye uzifake ngokwenkqubo yokutywina echaziweyo. I-sealant kufuneka isetyenziswe ngokulinganayo nangomlinganiselo ofanelekileyo, kwaye ii-gaskets mazifakwe ngokuthe tyaba kwaye zingenamibimbi. Qinisa iibholiti zokudibanisa ngokulinganayo ukuqinisekisa isiphumo sokutywina kunye nokuthintela ukuvuza okuphakathi.

Ukufakelwa koMbane kunye nezixhobo

Uqhagamshelo loMbane: Ngokwemizobo yombane yezixhobo, qhagamshela iintambo zombane, iintambo zolawulo, kunye nezinye iintambo zombane. Qinisekisa ukuba uqhagamshelo lombane luqinile kwaye iingcingo zichanekile, kwaye ukufakwa kweentambo zombane kuhambelana nemigaqo efanelekileyo. Emva kokuba ufakelo lugqityiwe, lungisa inkqubo yombane ukuze ujonge ukuba ukusebenza kombane kwezixhobo kuqhelekile na.

Ukufakwa kwezixhobo: Faka izixhobo zokubeka esweni ezifana nobushushu, uxinzelelo, kunye nesantya sokuhamba kwamanzi ukuqinisekisa ukuba iindawo zokufakela izixhobo zifanelekile kwaye kulula ukuzijonga nokuzigcina. Uqhagamshelo lwezixhobo kufuneka luchaneke kwaye lungabi nazimpazamo, kwaye udluliselo lwesignali kufuneka luzinze. Emva kokuba ufakelo lugqityiwe, lungisa kwaye ulungise izixhobo ukuqinisekisa ukuba idatha yokulinganisa ichanekile kwaye ithembekile.

Ukulungiswa kweNkqubo kunye noKwamkelwa

Ukulungisa iimpazamo ngomatshini omnye: Emva kokuba ufakelo lwezixhobo lugqityiwe, yenza ukulungisa iimpazamo ngomatshini omnye. Qala izixhobo uze ujonge ukuba izixhobo zisebenza kakuhle na kwaye nokuba kukho ingxolo okanye ukungcangcazela okungaqhelekanga. Jonga iiparameter zokusebenza kwezixhobo, ezinje ngobushushu, uxinzelelo, kunye nesantya sokuhamba, ukuqinisekisa ukuba zonke iiparameter ziyahlangabezana neemfuno zoyilo. Ukuba kukho naziphi na iingxaki, yima umatshini ngexesha ukuze ulungise iimpazamo de izixhobo zisebenze ngokwesiqhelo.

Ukulungisa iimpazamo ngokudibeneyo: Ngokusekelwe ekulungiseni iimpazamo ngomatshini omnye, yenza ulungiso-zimpazamo oludibeneyo lwenkqubo. Lingisa iimeko zokusebenza zemveliso yokwenyani kwaye usebenzise yonke inkqubo ukujonga iimeko zokusebenza ezisebenzisanayo phakathi kwezixhobo kunye nezinye izixhobo zenkqubo. Jonga uzinzo lokusebenza kwenkqubo kwaye ubone ukuba ukusebenza kakuhle kotshintshiselwano lobushushu kufikelela kwisalathiso soyilo. Lungisa iingxaki ezifunyenwe ngexesha lenkqubo yokulungisa iimpazamo ngexesha elifanelekileyo ukuqinisekisa ukusebenza okuthembekileyo kwenkqubo.

Ukwamkelwa kunye nokuHanjiswa: Emva kokuba ulungiso lweengxaki lugqityiwe, lungiselela abasebenzi abafanelekileyo ukuba bamkele izixhobo. Yenza uhlolo olupheleleyo kunye novavanyo lomgangatho wokufakwa kwezixhobo, ukusebenza kwazo, ukhuseleko, kunye nezinye izinto ngokwemigangatho yokwamkelwa. Emva kokuba ukwamkelwa kuqinisekisiwe, sayina amaxwebhu okwamkelwa, kwaye izixhobo zisiwe ngokusemthethweni ukuze zisetyenziswe.

Iindawo Zokusebenza Nokugcina Emva Kokufakelwa

Lawula Ngokungqongqo Iimeko Zokusebenza

Ulawulo lobushushu: Ngexesha lokusebenza, akuvumelekanga ngokungqongqo ukuba ubushushu bezixhobo budlule umda ophezulu woyilo ukuze kuthintelwe ukuqhekeka kobushushu obubangelwa kubushushu obugqithisileyo. Jonga utshintsho lobushushu bezixhobo ngexesha langempela, seta umda we-alamu yobushushu obufanelekileyo, kwaye uthathe amanyathelo okupholisa ngexesha apho ubushushu bungaqhelekanga.

Ulawulo loxinzelelo: Qinisekisa ukuba uxinzelelo olusebenzayo lwezixhobo lukwinqanaba elichaziweyo ukuthintela ukungasebenzi kakuhle kwee-welds ngenxa yoxinzelelo olugqithisileyo. Faka isixhobo sokujonga uxinzelelo ukuze ujonge uxinzelelo ngexesha langempela. Xa uxinzelelo lutshintsha ngokungaqhelekanga, khawuleza uphande unobangela uze wenze uhlengahlengiso.

Ulawulo lokwahluka kobushushu: Nciphisa impembelelo yomahluko kubushushu phakathi kwemidiya eshushu nebandayo ukuze kuthintelwe ukudinwa kwe-plate welds okubangelwa kuxinzelelo olukhulu lobushushu. Ngexesha lenkqubo yokuqalisa nokuvala izixhobo, lawula ngokufanelekileyo isantya sokuhamba kunye nesantya sokutshintsha kobushushu bemidiya eshushu nebandayo ukuze kufezekiswe utshintsho olugudileyo.

Qinisa uLawulo lweFluid Media

Ulawulo lweMidiya Eyonakalisayo: Kwimidiya erhabaxa, jonga rhoqo ixabiso layo le-pH ukuqinisekisa ukuba iimpawu zemidiya zihambelana nezinto zokuwelda zesixhobo. Umzekelo, kwiimeko zokusebenza ezine-chlorine eninzi, khetha izixhobo ezenziwe ngezinto ze-C – 276. Ngokwendlela ezirhabaxa ngayo izixhobo, yenza amanyathelo afanelekileyo okulwa nokurhabaxa ukuze wandise ubomi besixhobo.

Unyango lwe-Particle Purities: Xa uphatha imidiya enomxholo ophezulu wokungcola, kufuneka kufakwe isihluzo, kwaye ukuchaneka kokuhluza kufuneka kuhlangabezane neemfuno zokusebenza kwesixhobo. Kwangaxeshanye, ngokweempawu zemidiya, khetha izixhobo ezinetshaneli ebanzi ukunciphisa umngcipheko wokuvaleka. Coca isihluzo rhoqo ukuthintela ukusebenza okuqhelekileyo kwesixhobo ekuchaphazelekeni ngenxa yokuvaleka kwesihluzo.

Iinkcukacha zokucoca: Akuvumelekanga ngokupheleleyo ukusebenzisa izinto zokucoca ezine-chloric acid ukucoca izixhobo. Ukucoca okungafanelekanga kuya kukhokelela ekuqhekekeni nasekuqhekekeni kwee-welds. Yenza isicwangciso sokucoca sesayensi, kwaye ukhethe iindlela ezifanelekileyo zokucoca, ukuhlamba nge-alkali, okanye iindlela zokucoca ngokwasemzimbeni ngokweempawu zemidiya kunye neemeko zokusebenza kwezixhobo. Umjikelo wokucoca uyacetyiswa ukuba ube kanye ngonyaka okanye rhoqo kwiinyanga ezi-6 ukuya kwezi-12 zokusebenza. Emva kokucoca, fumana ngokukhawuleza uxinzelelo, isantya sokuhamba, kunye nokusebenza kakuhle kokutshintshana kobushushu kwezixhobo ukuqinisekisa ukuba ukusebenza kwezixhobo kubuyela kwisiqhelo.

Hlanganisa ukuSebenza okuNgcono kunye noLondolozo lweMihla ngemihla

Nika amandla iNkqubo yokuJonga eNgqondileyo: Nika indima ye-“Smart Eye” idlalwe ngokupheleleyo™"Inkqubo yokubeka esweni ekrelekrele ukufezekisa ukujonga ngexesha langempela kunye nesilumkiso sangethuba seeparameters ezifana nobushushu, ukuhla koxinzelelo, kunye nokusebenza kakuhle kwezixhobo. Ngokusebenzisa uhlalutyo lwedatha yenkqubo, fumana ngokukhawuleza iimpazamo ezinokubakho kunye neengxaki zokwehla kokusebenza kwezixhobo, fumana ngokukhawuleza iindawo zokusilela, kwaye unike isikhokelo esikude sokugcinwa ukuze kuphuculwe ukusebenza kakuhle kwezixhobo.

Uhlolo lwemihla ngemihla kunye nokugcinwa: Misela inkqubo yokuhlola yemihla ngemihla yezixhobo, kwaye ujonge rhoqo imeko yokusebenza kwezixhobo, kubandakanya ukubonakala kwezixhobo, iindawo zonxibelelwano, kunye nokufundwa kwezixhobo. Jonga ukuba kukho naziphi na iimeko ezingaqhelekanga ezifana nokuvuza, ingxolo engaqhelekanga, kunye nokungcangcazela kwezixhobo, kwaye ujongane neengxaki ezifunyenweyo ngexesha elifanelekileyo. Coca kwaye ugcine izixhobo rhoqo ukuze ugcine umphezulu wezixhobo ucocekile kwaye uthintele ukuqokelelwa kothuli kunye nokungcola ekuchaphazeleni ukusasazwa kobushushu kunye nokusebenza kwezixhobo.

Amanyathelo Obuchwephesha Okuthintela Ukungaphumeleli Kwe-Weld

Ulawulo lokuguquguquka kobushushu: Kuphephe ukuguquguquka okukhulu kobushushu bezixhobo ukuze kuncitshiswe ukudinwa kobushushu kwindawo yokuwelda. Lungiselela inkqubo yemveliso, cwangcisa ngokufanelekileyo ixesha lokuqalisa nelokuvala kwezixhobo, kwaye unciphise impembelelo yotshintsho lobushushu kwi-welds.

Ukuqinisekisa Umgangatho Wokuwelda:Khetha inkqubo yokuwelda efanelekileyo kwaye uyakhe ngokungqongqo ngokuhambelana nemigaqo yenkqubo yokuwelda. Yenza uvavanyo olungonakalisiyo (njengokufunyanwa kweziphene ze-X-ray) kwiindawo zokuwelda ukuqinisekisa ukuba umgangatho wokuwelda uyahlangabezana neemfuno. Kwimeko yolwelo olubolayo, khetha iingcingo zokuwelda ezifanayo kunye nezinto zokuthintela ukuveliswa kwemifantu yokubola koxinzelelo.

Ukukhululeka kuxinzelelo: Ngexesha lokufakelwa kwezixhobo kunye noqhagamshelo lwemibhobho, thabatha amanyathelo okukhulula uxinzelelo lwezixhobo kunye nemibhobho ukuze uphephe umonakalo kwi-welds ebangelwa kukuxinana koxinzelelo. Umzekelo, misela ngokufanelekileyo izixhasi zemibhobho, izinto ezixhasayo, njl.njl. ukuze ufunxe uxinzelelo olubangelwa kukwanda kobushushu kunye nokuxinana kwemibhobho.

Yenza amaqhinga okwandisa ubomi bezixhobo

Ulawulo lweeNdawo eziSebenzayo: Yila icebo leendawo ezingasetyenziswanga, kwaye ulungiselele ii-plate bundles okanye iimodyuli ngokwemeko yokusebenza kwezixhobo kunye nomjikelo wokutshintshwa kweendawo ezibuthathaka. Qinisekisa ukuba xa izixhobo zingasebenzi, iindawo ezingasetyenziswanga zinokutshintshwa ngexesha elifanelekileyo, ukunciphisa ixesha lokulinda lokungasebenzi kunye nokuqinisekisa ukuqhubeka kwemveliso.

Ucwangciso Lokugcinwa: Cwangcisa ngokwesayensi umjikelo wokugcinwa kwezixhobo. Kucetyiswa ukuba kwenziwe uhlolo olupheleleyo rhoqo kanye ngonyaka, kwaye kwiinkqubo ezinzima, kufuneka kwenziwe uhlolo rhoqo kwiinyanga ezintandathu. Yenza isicwangciso solondolozo esineenkcukacha, wenze uhlolo olupheleleyo, ulondolozo, kunye nokulungiswa kwezixhobo, kwaye ufumanise ngokukhawuleza kwaye ujongane neengxaki ezinokubakho ukuze wandise ubomi benkonzo yezixhobo.

Ulawulo lweeNkcukacha zoMsebenzi:Qinisa uqeqesho lwabaqhubi ukuze bakwazi ukuqhelanisa iindlela zokulungisa uxinzelelo kunye nobushushu bezixhobo kunye nokukwazi ukugweba idatha engaqhelekanga. Yenza iinkqubo ezingqongqo zokusebenza kwezixhobo, ulungelelanise indlela abaziphethe ngayo abaqhubi, kwaye uphephe umonakalo wezixhobo obangelwa kukungasebenzi kakuhle.

Ukuphucula Okusingqongileyo:Qinisa ulawulo lwendawo yokufakela izixhobo, thatha amanyathelo okunciphisa impembelelo yemithombo yokungcangcazela kwizixhobo, kwaye uqinisekise ukuba izixhobo zifakwe kakuhle. Yenza umsebenzi olungileyo kumanyathelo okumelana nokufuma kunye nokungagqwali, khusela izixhobo kwiimeko zokusingqongileyo, kwaye udale imeko efanelekileyo yokusebenza kwezixhobo.

Isiphelo

Njengezixhobo eziphambili zokudlulisa ubushushu ngokufanelekileyo kwicandelo lemizi-mveliso, umgangatho wokufakelwa kunye nokusebenza kunye nokugcinwa kwee-plate heat exchangers ezidityaniswe ngokupheleleyo zinxulumene ngokuthe ngqo nokusebenza kwezixhobo kunye nokusebenza kakuhle kwemveliso yamashishini. Ngokulandela isikhokelo sokufakela esingentla ngokwesayensi nesingqongqo kunye neendawo zokusebenza nokugcinwa ngononophelo, ukusebenza okuzinzileyo nokufanelekileyo kwee-plate heat exchangers ezidityaniswe ngokupheleleyo kwiimeko ezinzima zokusebenza ezifana nobushushu obuphezulu, uxinzelelo oluphezulu, ukugqwala okulula, kunye nokuvaleka okulula kunokuqinisekiswa, kunceda amashishini ukuba afezekise injongo "yokusebenza ngokukhuselekileyo + ukunciphisa iindleko kunye nokuphucula ukusebenza kakuhle".

I-Shanghai Heat Transfer Equipment Co., Ltd., njengomboneleli ophambili wezisombululo zokutshintsha ubushushu kushishino, enamava amaninzi kunye neqela lobuchwephesha elinobuchule, inokukunika izisombululo ezenzelwe wena zezixhobo zokutshintsha ubushushu zepleyiti ezitshixiweyo ngokupheleleyo kunye nenkxaso yobugcisa ebanzi. Nokuba kukukhetha izixhobo, isikhokelo sokufakela, ukusebenza kunye nokugcinwa, okanye ukuphathwa kweempazamo, siya kukukhonza ngentliziyo yonke. Ukuba ufuna ulwazi oluthe kratya okanye uncedo, nceda uzive ukhululekile ukunxibelelana nathi.:

I-imeyile:

zhanglimei@shphe.com

qiuying@shphe.com

I-WhatsApp / Iselfowuni:+86 15201818405

I-WhatsApp / Iselfowuni: +86 13671925024

Ixesha leposi: Matshi-25-2025