Intshayelelo

Ubusazi na ukuba ukungawukhathaleli rhoqo umsebenzi wakhoisixhobo sokufudumeza ipleyiti ye-gasketinokubangela ukuba ukusebenza kwayo kokudlulisa ubushushu kwehle ukuya kuthi ga kwi-30%? Ukwehla okunjalo kuchaphazela kakhulu ukusetyenziswa kwamandla kunye neendleko zokusebenza. Njengoko amashishini eqhubeka elandela ukusebenza okuphezulu kunye nemisebenzi ezinzileyo, ukugcina ukusebenza kakuhle kwe-heat exchanger akusekho mfuneko—kubalulekile.

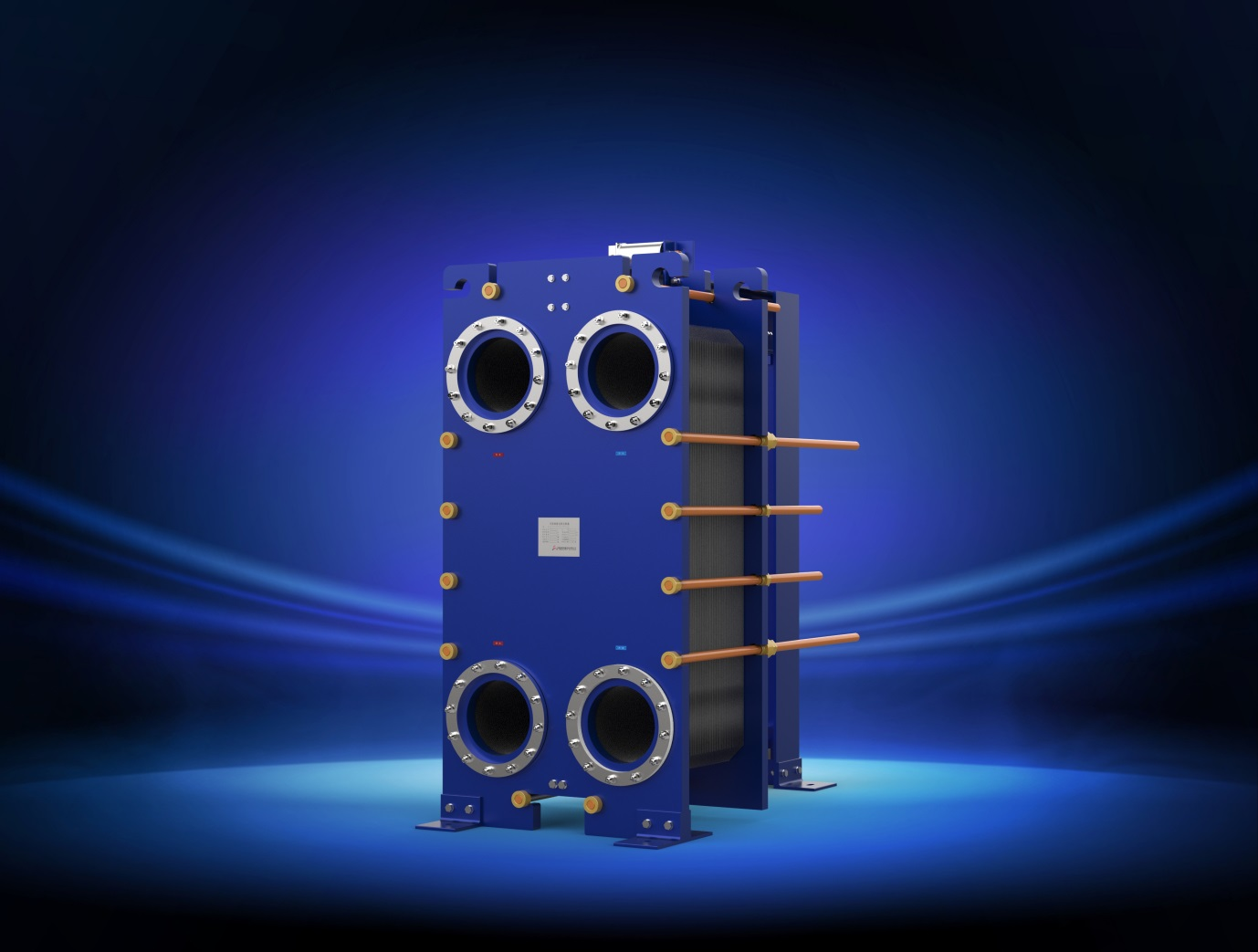

Izitshintshi zobushushu ze-gasket plate zisetyenziswa kakhulu kumacandelo afana nokulungiswa kokutya, iikhemikhali ezintle, ubunjineli bamayeza, kunye neenkqubo ze-HVAC. Nangona kunjalo, imijelo yokuhambahamba emxinwa phakathi kweepleyiti inokuba nokungcola, ukwakheka kwe-biofilm, kunye nokuqokelelana kwamasuntswana, okukhokelela ekuchaseni okuphezulu kobushushu, ukwehla koxinzelelo okungaqhelekanga, kunye nokusilela kwezixhobo.

Esi sikhokelo sibonelela ngenkqubo yokucoca ebanzi, ethatha inyathelo ngenyathelo equka ukulungiselela, ukuqhaqha, ukucoca, ukuphinda udibanise kunye nokuvavanya, kunye namaqhinga okukhusela ukugcinwa, ekunceda useke inkqubo yobuchwephesha yolawulo lokugcinwa.

1. Ukulungiselela: Izixhobo ezibalulekileyo kunye namanyathelo okhuseleko

Isikrufu seTorque: Siqinisekisa ukuba ibolti iyaqiniswa ngokulinganayo ngexesha lokuhlanganiswa kwakhona ukuthintela ukuvuza okanye ukuguquka kwepleyiti.

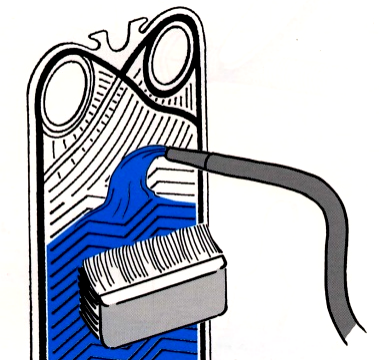

Iibhrashi ezithambileyo kunye neephedi ezingarhawuzeliyo: Zisetyenziselwa ukususa ngokwasemzimbeni iimfumba ngaphandle kokukrwela umphezulu wepleyiti.

Ijethi yamanzi enoxinzelelo oluphezulu: Inceda ekuhlambululeni iipleyiti kakuhle nasekususeni iikhemikhali eziseleyo.

Izixhobo zokuzikhusela: Nxiba iiglavu kunye neeglasi kulo lonke ixesha ukuze uphephe ukwenzakala ngamakhemikhali okanye okungcolisayo.

Umoya ongenisayo: Qinisekisa ukuba umoya ujikeleza kakuhle, ingakumbi xa usebenzisa izinto zokucoca ezine-asidi.

Ukwahlulwa kwamandla: Nqamula imithombo yombane kunye ne-hydraulic/pneumatic ngaphambi kokuba uqale umsebenzi.

Yenza uhlolo olubonakalayo phambi kokuba ucoce. Jonga ukuba akukho mhlwa, ukuguga kwe-gasket, okanye umonakalo kwifreyimu. Buyisela naziphi na iindawo ezineziphene phambi kokuba uqhubeke.

2. Ukuqhaqha i-Heat Exchanger

Khulula iibholithi kancinci kancinci ngokulandelelana okuthe tyaba ukuze uphephe ukugoba kwepleyiti.

Susa iipleyiti ngononophelo, ugcine ulungelelwano lwangaphambili ukuze kuthintelwe iimpazamo zendlela yokuhamba kwamanzi.

Bhala ilebheli uze ubhale phantsi iindawo zepleyiti kunye negasket ukuze ziphinde zihlanganiswe ngokuchanekileyo.

Beka iipleyiti kwindawo ethambileyo ukuze uphephe ukukrwela okanye ukungqubana.

Phatha ii-gaskets ngononophelo, uphephe ukuvezwa kumaqondo obushushu aphezulu okanye iikhemikhali ezirhabaxa.

3. Iipleyiti zokucoca kunye neeGasket

Sebenzisa ii-asidi ezibuthathaka ezixutyiweyo ezifana ne-citric acid okanye i-phosphoric acid ukunyibilikisa isikali kunye needipozithi ze-organic.

Ukuntywila kokuqala: imizuzu engama-30–90 kuxhomekeke ekubeni ungcoliseke kangakanani.

Ziphephe ii-asidi ezinamandla njenge-nitric okanye i-hydrochloric acid ukuze uthintele ukugqwala phakathi kweegranular.

Hlikihla ngesandla ngeebristles ezithambileyo okanye izixhobo zokucoca ezikhethekileyo.

Xa ungcolisa kakhulu, cinga ngokusebenzisa iibrashi ezijikelezayo okanye ukungcangcazela okuthambileyo, ulawule ubunzulu bokucoca.

Hlamba kakuhle ngamanzi acocekileyo okanye acocekileyo usebenzisa ijethi enoxinzelelo oluphezulu.

Hlola ipleyiti nganye ngononophelo ukuze ubone ukuba ayinamingxuma, imifantu, okanye ukuguguleka.

Jonga ukuqina kwe-gasket kunye nokunamathela; tshintsha ukuba kuyimfuneko.

4. Ukudibanisa kwakhona kunye novavanyo

Faka kwakhona iipleyiti ngokweendawo ezirekhodiweyo kunye necala lokuhamba kwamanzi.

Qinisekisa ukuba ii-gaskets zilingana kakuhle ngaphandle kokugoba, ukushukuma, okanye ukugqubana.

Qinisa iibholithi kancinci kancinci ngendlela efana nepatheni ye-crisscross usebenzisa isikrufu se-torque.

Landela imiqathango yomenzi we-torque ukuze uphephe ukuqina okanye ukuguquguquka.

Uvavanyo:

Yenza uvavanyo lokuqala lwamanzi oluphantsi koxinzelelo ukuze kuhlolwe ukuvuza kwamanzi.

Ukuba akukho kuvuza kufunyenweyo, yonyusa uxinzelelo kancinci kancinci ukuya kwinqanaba lokusebenza koyilo.

Bhala umhla wokucoca, iikhemikhali ezisetyenzisiweyo, uxinaniso, kunye nayo nayiphi na imiba echongiweyo.

Iifoto ezigciniweyo kunye nedatha yovavanyo yokulandelela ukugcinwa kwazo.

5. Iingcebiso zoLondolozo loKhuseleko

Yenza ngokwezifiso amaxesha okucoca ngokusekelwe kwiiyure zokusebenza, uhlobo lwemidiya, kunye neemeko zokusingqongileyo (ngesiqhelo rhoqo kwiinyanga ezi-6-12).

Nciphisa amaxesha phantsi kweemeko ezinzima njengokuphatha izinto eziqinileyo, amanzi anobunzima obuphezulu, okanye izixhobo ezixineneyo.

Faka izinzwa zobushushu, ukwehla koxinzelelo, kunye nesantya sokuhamba, ezidityaniswe neenkqubo.

Seta ii-alamu ezizenzekelayo ukuze ubone ukwehla kokusebenza kakuhle okanye ukwehla koxinzelelo okungaqhelekanga.

Qhuba uqeqesho lobugcisa rhoqo ngokudibanisa imisebenzi esebenzayo kunye nethiyori, uphucule amandla okuxilonga.

Isiphelo

Njengesixhobo esibalulekileyo sokudlulisa ubushushu, imeko yokusebenza kwe-plate heat exchanger ichaphazela ngokuthe ngqo uzinzo kunye nokusebenza kakuhle kwamandla kweenkqubo zonke. Iprothokholi yokucoca ecwangcisiweyo nesemgangathweni ayiphuculi kuphela ukusebenza kakuhle kotshintshiselwano lobushushu kodwa ikwandisa ubomi bezixhobo kwaye inciphisa amazinga okungasebenzi kakuhle.

Ukuseka inkqubo yokugcinwa kwezinto ngendlela ecwangcisiweyo—ukudibanisa ukujonga izivamvo, iinkonzo zobungcali, kunye noqeqesho lwangaphakathi—kuya kwandisa ixabiso lexesha elide lezinto zakho zokutshintsha ubushushu.

Ukuze ufumane iinkonzo zokucoca, inkxaso yokukhetha imveliso, okanye izisombululo zokugcina izinto zilungile, nceda unxibelelane nathius:

I-imeyile:

zhanglimei@shphe.com

qiuying@shphe.com

I-WhatsApp / Iselfowuni:+86 15201818405

I-WhatsApp / Iselfowuni: +86 13671925024

Ixesha leposi: Epreli-15-2025