Tšimong ea phetoho ea matla a mocheso oa indasteri,li-exchange tsa mocheso oa poleiti tse svetselitsoeng ka botlalo e se e le disebediswa tsa bohlokwa bakeng sa dikgwebo tse ngata ho fihlella phetiso e sebetsang hantle ya mocheso le paballo ya matla, ka lebaka la melemo ya tsona e ikgethang ya tshebetso. Leha ho le jwalo, ho kenya ka mahlale le ka maemo ke ntho ya bohlokwa hore di etse tshebetso ya tsona e ntle ka ho fetisisa. Tataiso e latelang e qaqileng ya mohato ka mohato e tla o thusa ho laola tshebetso ya ho kenya ka nepo, ho lokolla ka botlalo bokgoni ba di-plate tse welted ka botlalo, le ho kenya tshusumetso e matla tlhahisong le tshebetsong ya dikgwebo.

Kutloisiso e Tebileng ea Melemo e Ikhethang ea Li-Converter tsa Mocheso oa Lipoleiti tse Welded ka Botlalo

Melemo ea sebopeho le ts'ebetso ea li-plate exchanger tse kopantsoeng ka botlalo ke senotlolo sa ts'ebetso ea tsona e ikhethang maemong a rarahaneng a ts'ebetso. Sebopeho sa tsona se kopantsoeng ka botlalo se tlohela li-gasket tsa rabara tsa setso 'me se fihlella ho koala ka theknoloji e nepahetseng ea ho kopanya li-plate. Moralo ona o fa lisebelisoa ts'ebetso e ntle ea ts'ebetso e tsitsitseng ea nako e telele ntle le ho lutla libakeng tse nang le mocheso o phahameng le khatello e phahameng. Moralo oa kanale e pharaletseng ke ntlha e kholo, haholo-holo e loketseng ho sebetsana le mecha e rarahaneng e nang le likaroloana tse tiileng, litšila tsa faeba, le viscosity e phahameng, e fokotsang haholo kotsi ea ho thijoa le ho hola, le ho fokotsa khafetsa ea tlhokomelo ea lisebelisoa.

Mabapi le bokgoni ba phetisetso ya mocheso, sebopeho se ntlafaditsweng sa mahlaka se ka bopa phallo e matla e ferekanyang nakong ya tshebetso ya phallo ya mokelikeli, e leng se ntlafatsang haholo phello ya phapanyetsano ya mocheso. Ha ho bapiswa le disebediswa tsa khetla le tube, bokgoni ba phetisetso ya mocheso bo eketswa ka ho feta 20%, e leng se bolokang tjhelete e ngata ya eneji bakeng sa dikgwebo. Mabapi le kgetho ya thepa, e akaretsa mefuta e fapaneng ya disebediswa tse hanelang mahlaka haholo tse kang tshepe e sa ruseng, motswako wa titanium, motswako o thehilweng ho nickel, le 254SMO. Ebang ke maemong a tshebetso a nang le asiti e matla kapa a alkaline e matla, e ka bapiswa ka nepo ho netefatsa tshebetso e tsitsitseng ya nako e telele ya disebediswa.

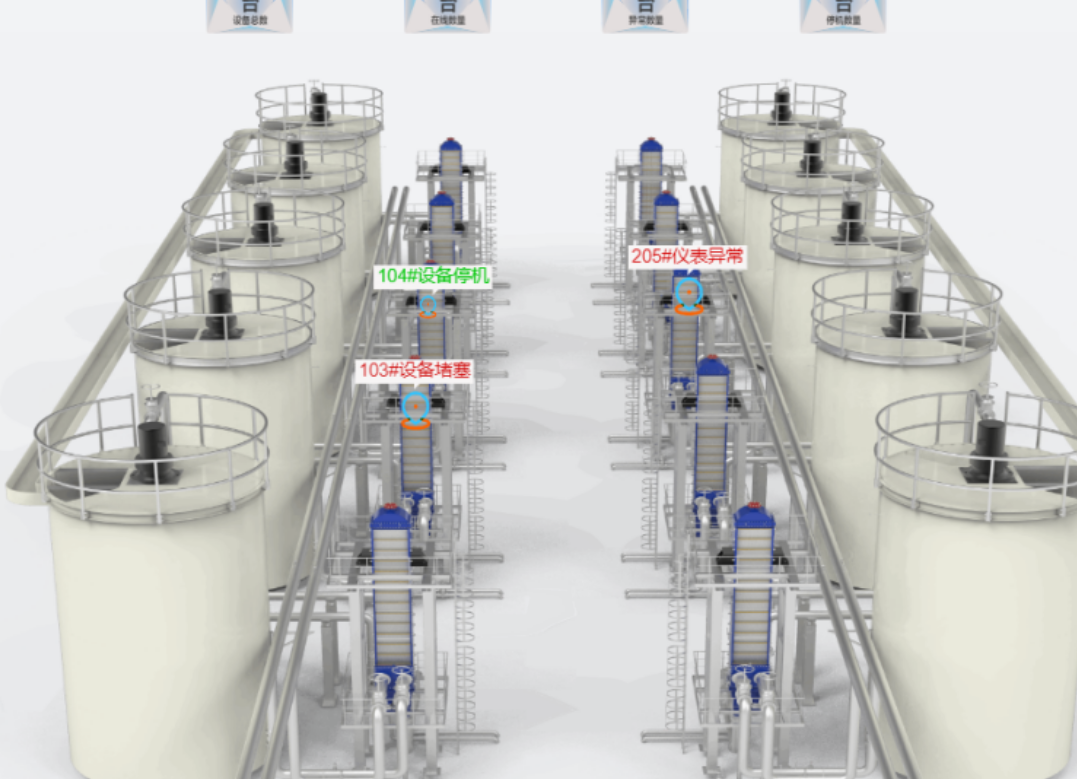

Ho phaella moo, sistimi e bohlale ea ho beha leihlo ea "Smart Eye ™" e nang le lisebelisoa e ka nkoa e le "boko ba dijithale" ba lisebelisoa, bo ka behang leihlo liparamente tsa bohlokoa ka nako ea sebele tse kang ho theoha ha mocheso le khatello. Ka li-algorithms tse bohlale, e ka fihlella temoso ea pele ea othomathiki le ntlafatso ea ts'ebetso ea matla, ea boloka boemo ba ts'ebetso ea lisebelisoa bo laoloa le ho tsamaisa tlhahiso e sireletsehileng le ts'ebetso e sebetsang hantle.

Tlhaloso ea Mohato ka Mohato ea ho Kenya Li-Exchange tsa Mocheso oa Lipoleiti tse Welded ka Botlalo

Tokisetso ea Pele: Ho Rala Motheo o Tiileng bakeng sa ho Kenya

- Phuputso le Moralo oa Sebaka: Pele ho kenngoa, ho lokela ho etsoa tlhahlobo e felletseng ea sebaka ho netefatsa hore ho na le sebaka se lekaneng sa ho kenya le hore se fihlela litlhoko tsa litekanyo tsa lisebelisoa. Sebaka seo se lokela ho ba le maemo a matle a moea, se be hole le libaka tsa khase tse nang le mocheso o phahameng, mongobo le tse senyang, 'me se qobe tšitiso e tsoang mehloling ea ho thothomela. Ka nako e ts'oanang, rera sebaka sa ts'ebetso le phihlello ea tlhokomelo ho potoloha lisebelisoa ho nolofatsa tlhokomelo le tokiso hamorao.

Tlhahlobo ea Lisebelisoa le Thepa: Kamora hore lisebelisoa li fihle, hlahloba ka hloko lethathamo la liphutheloana ho netefatsa hore likarolo tsohle tsa lisebelisoa li phethehile 'me ha ho na tšenyo kapa ho fetoha ha ponahalo. Tsepamisa maikutlo ho hlahlobeng boleng ba ho tjheseletsa ba lipoleiti, 'me u hlahlobe hore na li-weld lia tšoana ebile lia tsoela pele, le hore na ho na le liphoso tse kang masoba le mapetso. Haeba ho na le lintho tse sa tloaelehang, buisana le mofani oa thepa ka nako e loketseng ho sebetsana le tsona ho netefatsa hore boleng ba lisebelisoa bo fihlela maemo.

Tokisetso ea Sesebelisoa le Lintho Tse BoleloangLokisetsa mefuta eohle ea lisebelisoa tse hlokahalang bakeng sa ho kenya, joalo ka li-wrenches, lisebelisoa tsa ho phahamisa, le maemo. Ka nako e ts'oanang, ho latela litlhoko tsa ho kenya, lokisa lisebelisoa tse thusang joalo ka sealant le li-gasket ho netefatsa hore boleng ba thepa bo fihlela litlhoko tsa ts'ebetso ea lisebelisoa.

Ho Beha Lisebelisoa le ho Kenya Motheo

Sebaka se Nepahetseng: Fumana sebaka se nepahetseng sa ho kenya lisebelisoa sebakeng sa ho kenya ho latela litšoantšo tsa moralo le phallo ea ts'ebetso. Sebelisa lisebelisoa tse kang boemo ho netefatsa hore phoso ea boemo ba ho kenya lisebelisoa e ka har'a moeli o boletsoeng ho qoba phallo e sa lekanang ea mokelikeli e bakoang ke tšekamelo ea ho kenya, e amang phello ea phapanyetsano ea mocheso.

Kaho ea Motheo: Motheo oa lisebelisoa o lokela ho ba le matla le botsitso bo lekaneng ho mamella boima le ho thothomela ha lisebelisoa nakong ea ts'ebetso. Bokaholimo ba motheo bo lokela ho ba bataletse ebile bo boreleli. Ha u kenya liboutu tsa ankora kapa u kenya setsi, laola ka tieo boemo ba tsona le bophahamo ho netefatsa hore li lumellana hantle le masoba a ho kenya lisebelisoa. Kamora hore kaho ea motheo e phetheloe, etsa ho lokisa, 'me lisebelisoa li ka kenngoa feela ka mor'a hore matla a fihlelle litlhoko.

Ho Phahamisa le ho Beha Lisebelisoa Sebakeng se le Seng

Moralo oa ho Phahamisa: Ho ya ka boima, boholo ba disebediswa, le maemo a sebaka sa ho kenya, theha moralo wa saense le o utlwahalang wa ho phahamisa. Kgetha disebediswa tse loketseng tsa ho phahamisa le disebediswa tsa ho phahamisa ho netefatsa polokeho le botshepehi ba tshebetso ya ho phahamisa. Nakong ya ho phahamisa, qoba ho thulana le ho ntsha disebediswa, mme o sireletse bokahodimo le dikarolo tsa ho tjheseletsa tsa disebediswa.

Sebaka se Boreleli: Nakong ea ts'ebetso ea ho phahamisa le ho beha lisebelisoa, butle-butle fetola boemo ba lisebelisoa ho etsa hore li oele ka nepo holim'a liboutu tsa ankora ea motheo kapa motheo. Sebelisa boemo ho lemoha botsitso ba lisebelisoa hape. Haeba ho na le ho kheloha, etsa liphetoho tse nyane ka ho fetola li-gasket le mekhoa e meng ho netefatsa hore lisebelisoa li kentsoe ka ho rapama le ka tieo.

Kalafo ea Khokelo le ho Tiisa Liphaephe

Ho kenya liphaephe: Kenya liphaephe ho latela litlhoko tsa moralo ho netefatsa hore litsela tsa liphaephe lia utloahala le hore moralo o makhethe. Ha u hokahanya liphaephe le lisebelisoa, qoba ho li hokahanya ka thata ho thibela khatello ea liphaephe ho fetisetsoa lisebelisoa, e leng se amang ts'ebetso e sireletsehileng ea lisebelisoa. Bakeng sa liphaephe tsa mocheso o phahameng le khatello e phahameng, lisebelisoa tse hlokahalang tsa puseletso li lokela ho hlongoa ho monya ho falla ho bakoang ke katoloso ea mocheso le ho honyela ha liphaephe.

Kalafo ea ho Tiisa: Ho kwala kgokelo pakeng tsa phaephe le disebediswa ho bohlokwa haholo. Sebedisa sekwadi kapa di-gasket tsa boleng bo hodimo mme o di kenye ho ya ka tshebetso e boletsweng ya ho kwala. Sekwadi se lokela ho sebediswa ka ho lekana le ka tekanyo e loketseng, mme di-gasket di lokela ho kenngwa di bataletse mme di se na makukuno. Tiisa diboutu tse hokelang ka ho lekana ho netefatsa phello ya ho kwala le ho thibela ho dutla ha metsi ka tekanyo e mahareng.

Ho Kenya Motlakase le Lisebelisoa

Khokahano ea Motlakase: Ho ya ka ditshwantsho tsa motlakase tsa disebediswa, hokela dithapo tsa motlakase, dithapo tsa taolo, le dithapo tse ding tsa motlakase. Netefatsa hore dikgokelo tsa motlakase di tiile mme dithapo di nepahetse, mme ho bewa ha dithapo tsa motlakase ho latela ditlhaloso tse amehang. Kamora hore ho kenngwa ho phethelwe, lokisa tsamaiso ya motlakase ho hlahloba hore na tshebetso ya motlakase ya disebediswa e tlwaelehile.

Ho kenya lisebelisoa: Kenya disebediswa tsa ho beha leihlo tse kang mocheso, kgatello le sekgahla sa phallo ho netefatsa hore maemo a ho kenya disebediswa a utlwahala mme a bonolo ho a bona le ho a hlokomela. Dikgokelo tsa disebediswa di lokela ho nepahala le ho se be le diphoso, mme phetiso ya letshwao e lokela ho ba e tsitsitseng. Kamora hore ho kenngwa ho phethelwe, lekanyetsa le ho lokisa disebediswa ho netefatsa hore data ya tekanyo e nepahetse ebile e ka tshepahala.

Ho lokisa le ho Amohela Sistimi

Ho lokisa liphoso ka mochini o le mong: Kamora hore ho kenngwa ha disebediswa ho phethelwe, etsa diphoso tsa motjhini o le mong. Qala disebediswa mme o hlahlobe hore na disebediswa di sebetsa hantle le hore na ho na le lerata kapa ho thothomela ho sa tlwaelehang. Lekola diparamitha tsa tshebetso ya disebediswa, tse kang mocheso, kgatello le sekgahla sa phallo, ho netefatsa hore diparamitha tsohle di fihlela ditlhoko tsa moralo. Haeba ho na le diphoso tse itseng, emisa mochini ka nako ho rarolla diphoso ho fihlela disebediswa di sebetsa ka tsela e tlwaelehileng.

Ho lokisa bothata ba kopanelo: Ho latela mokhoa o tšoanelehang oa ho lokisa liphoso tsa mochini o le mong, etsa ho lokisa liphoso tsa sistimi ka kopanelo. Etsisa maemo a sebele a ts'ebetso ea tlhahiso 'me u tsamaise sistimi eohle ho hlahloba maemo a ts'ebetso a tšebelisano-'moho lipakeng tsa lisebelisoa le lisebelisoa tse ling tsa sistimi. Hlokomela botsitso ba ts'ebetso ea sistimi 'me u lemohe hore na katleho ea phapanyetsano ea mocheso e fihla ho index ea moralo. Lokisa mathata a fumanoeng nakong ea ts'ebetso ea ho lokisa liphoso ka nako e nepahetseng ho netefatsa ts'ebetso e tšepahalang ea sistimi.

Kamohelo le Phano: Kamora hore ho rarolloa ha diphoso ho phethelwe, hlophisa basebetsi ba amehang ho amohela disebediswa. Etsa tlhahlobo e felletseng le tlhahlobo ya boleng ba ho kenya disebediswa, tshebetso ya tshebetso, tshireletso ya polokeho, le dintlha tse ding ho ya ka maemo a kamohelo. Kamora hore kamohelo e tshwanelehe, saena ditokomane tsa kamohelo, mme disebediswa di tla romelwa semmuso bakeng sa tshebediso.

Lintlha tsa Ts'ebetso le Tlhokomelo Kamora ho Kenya

Laola Maemo a Mosebetsi ka Tieo

Taolo ea Mocheso: Nakong ea ts'ebetso, ho thibetsoe ka tieo hore mocheso oa lisebelisoa o fete moeli o kaholimo oa moralo ho qoba ho petsoha ha mokhathala oa mocheso oa li-weld tse bakoang ke mocheso o feteletseng. Ela hloko phetoho ea mocheso oa lisebelisoa ka nako ea sebele, beha moeli o utloahalang oa alamo ea mocheso, 'me u nke mehato ea ho pholisa ka nako eo mocheso o sa tloaelehang.

Taolo ea Khatello: Netefatsa hore khatello e sebetsang ea lisebelisoa e ka har'a moeli o boletsoeng ho thibela ho hloleha ha li-weld ka lebaka la khatello e feteletseng. Kenya sesebelisoa sa ho beha leihlo khatello ho beha leihlo khatello ka nako ea sebele. Ha khatello e fetoha ka mokhoa o sa tloaelehang, batlisisa sesosa kapele 'me u etse liphetoho.

Taolo ea Phapang ea Mocheso: Fokotsa tšusumetso ea phapang ea mocheso pakeng tsa mecha ea litaba e chesang le e batang ho qoba mokhathala oa li-weld tsa poleiti tse bakoang ke khatello e feteletseng ea mocheso. Nakong ea ts'ebetso ea ho qala le ho koala lisebelisoa, laola ka nepo sekhahla sa phallo le sekhahla sa phetoho ea mocheso oa mecha ea litaba e chesang le e batang ho fihlela phetoho e boreleli.

Matlafatsa Tsamaiso ea Mecha ea Litaba ea Mokelikeli

Taolo ea Mecha ea phatlalatso e senyang: Bakeng sa mecha ea phatlalatso e senyang, hlahloba boleng ba pH ea eona khafetsa ho netefatsa hore litšobotsi tsa mecha ea phatlalatso li tsamaellana le thepa ea ho tjheseletsa ea lisebelisoa. Mohlala, maemong a ts'ebetso a nang le chlorine e ngata, khetha lisebelisoa tse entsoeng ka thepa ea C - 276. Ho latela ho bola ha mecha ea phatlalatso, theha mehato e utloahalang ea ho thibela ho bola ho eketsa bophelo ba ts'ebeletso ea lisebelisoa.

Kalafo ea Litšila tsa Likaroloana: Ha o sebetsana le mecha ea phatlalatso e nang le litšila tse ngata, ho tlameha ho kentsoe sefe, 'me ho nepahala ha sefe ho lokela ho fihlela litlhoko tsa ts'ebetso ea lisebelisoa. Ka nako e ts'oanang, ho latela litšobotsi tsa mecha ea phatlalatso, khetha lisebelisoa tse nang le kanale e pharaletseng ho fokotsa kotsi ea ho thibana. Hloekisa sefe khafetsa ho thibela ts'ebetso e tloaelehileng ea lisebelisoa hore e se ke ea angoa ke ho thibana ha sefe.

Litlhaloso tsa ho Hloekisa: Ho thibetsoe ka ho feletseng ho sebelisa lintho tse hloekisang tse nang le chloric acid ho hloekisa lisebelisoa. Ho hloekisa ka tsela e sa lokelang ho tla lebisa ho petsoheng le ho phunyeheng ha li-weld. Theha moralo oa ho hloekisa oa saense, 'me u khethe mekhoa e loketseng ea ho hlatsoa ka metsi, ho hlatsoa ka alkali, kapa ho ntša metsi ka mokhoa o nepahetseng ho latela litšobotsi tsa mecha ea phatlalatso le maemo a ts'ebetso ea lisebelisoa. Potoloho ea ho hloekisa e khothaletsoa hore e be hang ka selemo kapa likhoeli tse ling le tse ling tse 6 - 12 tsa ts'ebetso. Kamora ho hloekisa, lemoha kapele khatello, sekhahla sa phallo le katleho ea phapanyetsano ea mocheso ea lisebelisoa ho netefatsa hore ts'ebetso ea lisebelisoa e khutlela setloaeling.

Kopanya Ts'ebetso le Tlhokomelo e Bohlale le Tlhokomelo ea Letsatsi le Letsatsi

Nolofatsa Sistimi ea Tlhokomelo e Bohlale: Fana ka karolo e felletseng ea "Leihlo le Bohlale"™"Sistimi e bohlale ea ho beha leihlo ho fihlela tlhokomelo ea nako ea sebele ea boemo ba leholimo le temoso ea pele ea liparamente tse kang mocheso, ho theoha ha khatello le katleho ea lisebelisoa. Ka tlhahlobo ea data ea sistimi, fumana liphoso tse ka bang teng le mathata a ho senyeha ha ts'ebetso ea lisebelisoa kapele, fumana lintlha tsa liphoso kapele, 'me u fane ka tataiso e hole bakeng sa tlhokomelo ho ntlafatsa ts'ebetso le katleho ea lisebelisoa.

Tlhahlobo le Tlhokomelo ea Letsatsi le Letsatsi: Theha sistimi ea tlhahlobo ea lisebelisoa letsatsi le letsatsi, 'me u hlahlobe boemo ba ts'ebetso ea lisebelisoa khafetsa, ho kenyeletsoa ponahalo ea lisebelisoa, likarolo tsa khokahano, le lipalo tsa lisebelisoa. Hlahloba hore na ho na le maemo afe kapa afe a sa tloaelehang a kang ho lutla, lerata le sa tloaelehang, le ho thothomela ha lisebelisoa, 'me u sebetsane le mathata a fumanoeng ka nako. Hloekisa le ho boloka lisebelisoa khafetsa ho boloka bokaholimo ba lisebelisoa bo hloekile le ho thibela ho bokellana ha lerōle le litšila ho ama ho qhalana ha mocheso le ts'ebetso ea ts'ebetso ea lisebelisoa.

Mehato ea Tekheniki ea ho Thibela ho Hlōleha ha ho Welded

Taolo ea Phetoho ea Mocheso: Qoba ho feto-fetoha ho matla ha mocheso oa lisebelisoa ho fokotsa mokhathala oa mocheso oa sebaka sa ho tjheseletsa. Ntlafatsa ts'ebetso ea tlhahiso, hlophisa nako ea ho qala le ho koala ea lisebelisoa ka nepo, 'me u fokotse tšusumetso ea liphetoho tsa mocheso ho li-weld.

Ho netefatsa Boleng ba ho Welding:Khetha mokhoa o tšoanelehang oa ho tjheseletsa 'me u o hahe ka tieo ho latela litlhaloso tsa mokhoa oa ho tjheseletsa. Etsa liteko tse sa senyeheng (joalo ka ho lemoha liphoso tsa X-ray) likarolong tsa ho tjheseletsa ho netefatsa hore boleng ba ho tjheseletsa bo fihlela litlhoko. Tabeng ea mokelikeli o senyang, khetha lithapo tsa ho tjheseletsa tse tsamaellanang le thepa ho thibela ho hlaha ha mapetso a ho tjheseletsa ka khatello.

Phomolo ea Khatello ea Kelello: Nakong ea ho kenya lisebelisoa le ho hokela liphaephe, nka mehato ea ho lokolla khatello ea lisebelisoa le liphaephe ho qoba tšenyo ho li-weld tse bakoang ke khatello e phahameng. Mohlala, beha ka nepo litšehetso tsa liphaephe, li-compensator, jj. ho monya khatello e hlahisoang ke katoloso ea mocheso le ho honyela ha liphaephe.

Ho theha Maano a Katoloso ea Bophelo ba Lisebelisoa

Tsamaiso ea Likarolo tse Sirelelitsoeng: Rala leano la likarolo tse ling tse sa sebelisoeng, 'me u lokise liphutheloana tsa lipoleiti tse ling kapa li-module ho latela boemo ba ts'ebetso ea lisebelisoa le potoloho ea ho nkela likarolo tse kotsing sebaka. Netefatsa hore haeba lisebelisoa li hlōleha, likarolo tse ling li ka nkeloa sebaka ka nako e loketseng, ho fokotsa nako ea ho leta e sa sebetseng le ho netefatsa hore tlhahiso e tsoela pele.

Moralo oa Tlhokomelo: Rala potoloho ea tlhokomelo ea lisebelisoa ka saense. Ho khothalletsoa ho etsa tlhahlobo e felletseng ea kamehla hang ka selemo, 'me bakeng sa litsamaiso tse boima, tlhahlobo e lokela ho etsoa likhoeli tse ling le tse ling tse tšeletseng. Rala moralo o qaqileng oa tlhokomelo, etsa tlhahlobo e felletseng, tlhokomelo le tokiso ea lisebelisoa, 'me u fumane kapele le ho sebetsana le mathata a ka bang teng ho lelefatsa bophelo ba tšebeletso ea lisebelisoa.

Tsamaiso ea Tlhaloso ea Ts'ebetso:Matlafatsa koetliso ea basebetsi ho ba nolofalletsa ho tseba mekhoa ea ho fetola khatello le mocheso oa lisebelisoa le bokhoni ba ho ahlola lintlha tse sa tloaelehang. Rala mekhoa e thata ea ts'ebetso ea lisebelisoa, etsa hore boitšoaro ba basebetsi bo be boemong bo tloaelehileng, 'me u qobe tšenyo ea lisebelisoa e bakoang ke ts'ebetso e sa lokelang.

Ntlafatso ea Tikoloho:Matlafatsa taolo ea tikoloho ea ho kenya lisebelisoa, nka mehato ea ho fokotsa tšusumetso ea mehloli ea ho thothomela lisebelisoa, 'me u netefatse hore lisebelisoa li kentsoe ka thata. Etsa mosebetsi o motle mehatong e thibelang mongobo le e thibelang ho bola, sireletsa lisebelisoa khahlanong le mabaka a tikoloho, 'me u thehe boemo bo botle ba ts'ebetso bakeng sa lisebelisoa.

Qetello

Jwalo ka disebediswa tsa bohlokwa bakeng sa phetiso e sebetsang hantle ya mocheso tshimong ya diindasteri, boleng ba ho kenya le tshebetso le tlhokomelo ya di-converter tsa poleiti tse welilweng ka botlalo di amana ka ho toba le tshebetso ya disebediswa le bokgoni ba tlhahiso ya dikgwebo. Ka ho latela tataiso ya ho kenya mohato ka mohato ya saense le e matla le dintlha tse hlokolosi tsa tshebetso le tlhokomelo, tshebetso e tsitsitseng le e sebetsang hantle ya di-converter tsa poleiti tse welilweng ka botlalo maemong a thata a mosebetsi a kang mocheso o phahameng, kgatello e phahameng, ho bola habonolo, le ho thibana habonolo ho ka netefatswa, ho thusa dikgwebo ho fihlella sepheo sa "tshebetso e bolokehileng + phokotso ya ditjeo le ntlafatso ya bokgoni".

Shanghai Heat Transfer Equipment Co., Ltd., e le mofani ea ka sehloohong oa litharollo tsa phapanyetsano ea mocheso indastering, ka boiphihlelo bo bongata le sehlopha sa litsebi tsa botekgeniki, e ka u fa litharollo tse ikhethileng bakeng sa li-plate exchanger tse kopantsoeng ka botlalo le tšehetso e felletseng ea botekgeniki ea litsebi. Ebang ke khetho ea lisebelisoa, tataiso ea ho kenya, ts'ebetso le tlhokomelo, kapa ho sebetsana le liphoso, re tla u sebeletsa ka pelo eohle. Haeba u hloka tlhahisoleseling e eketsehileng kapa thuso, ka kopo ikutloe u lokolohile ho ikopanya le rona:

Imeile:

zhanglimei@shphe.com

qiuying@shphe.com

WhatsApp / Selefounu:+86 15201818405

WhatsApp / Selefounu: +86 13671925024

Nako ea poso: Hlakubele-25-2025