Mundima yekushandura simba rekupisa remaindasitiri,zvinotsinhanisa kupisa zveplate zvakasungirirwa zvizere zvave zvishandiso zvikuru zvemabhizinesi mazhinji kuti akwanise kutamisa kupisa zvakanaka uye kuchengetedza simba, nekuda kwezvakanaka zvavo zvekushanda. Zvisinei, kuisa kwesainzi uye kwakajairika chinhu chinodiwa kuti vashande zvakanaka. Gwaro rinotevera rakadzama nhanho nhanho richakubatsira kudzora maitiro ekuisa nemazvo, kusunungura zvizere kugona kwezvishandiso zvekupisa zveplate zvakasungirirwa zvizere, uye kupinza simba rakasimba mukugadzirwa nekushanda kwemabhizinesi.

Kunzwisisa Zvakadzama Mabhenefiti Akasarudzika EmaWelded Plate Heat Exchangers Akazara

Mabhenefiti echimiro uye mashandiro emidziyo yekupisa yeplate yakasungirirwa zvizere ndiwo musimboti wekushanda kwayo kwakanaka mumamiriro ekushanda akaomarara. Chimiro chayo chakasungirirwa zvizere chinosiya magasket erabha echinyakare uye chinoita kuti ivharwe kuburikidza netekinoroji chaiyo yekubatanidza maplate. Dhizaini iyi inopa michina iyi kushanda kwakanaka kwenguva refu isina kudonha mumvura munzvimbo dzine tembiricha yakakwira uye ine kumanikidzwa kwakakwira. Dhizaini yemugero wakafara chinhu chikuru, chakakodzera kubata michina yakaoma ine zvidimbu zvakasimba, tsvina yefiber, uye viscosity yakakwira, zvichideredza zvakanyanya njodzi yekuvharika nekukweva, uye kuderedza kuwanda kwekugadzirisa michina.

Panyaya yekushanda zvakanaka kwekutapurirana kwekupisa, chimiro chakagadziriswa che corrugated chinogona kugadzira kuyerera kwakasimba panguva yekuyerera kwemvura, zvichiwedzera zvakanyanya simba rekuchinjana kwekupisa. Kana tichienzanisa nemidziyo ye shell-and-tube, kushanda zvakanaka kwekutapurirana kwekupisa kunowedzerwa neanopfuura 20%, zvichichengetedza mari yakawanda yesimba kumabhizinesi. Panyaya yekusarudza zvinhu, inofukidza zvinhu zvakasiyana-siyana zvinodzivirira ngura zvakaita sesimbi isingatsvedzeri, titanium alloy, nickel-based alloy, uye 254SMO. Ingave iri mumamiriro ekushanda ane acid yakawanda kana ane alkaline yakawanda, inogona kuenzaniswa nemazvo kuti ive nechokwadi chekuti michina inoshanda kwenguva refu.

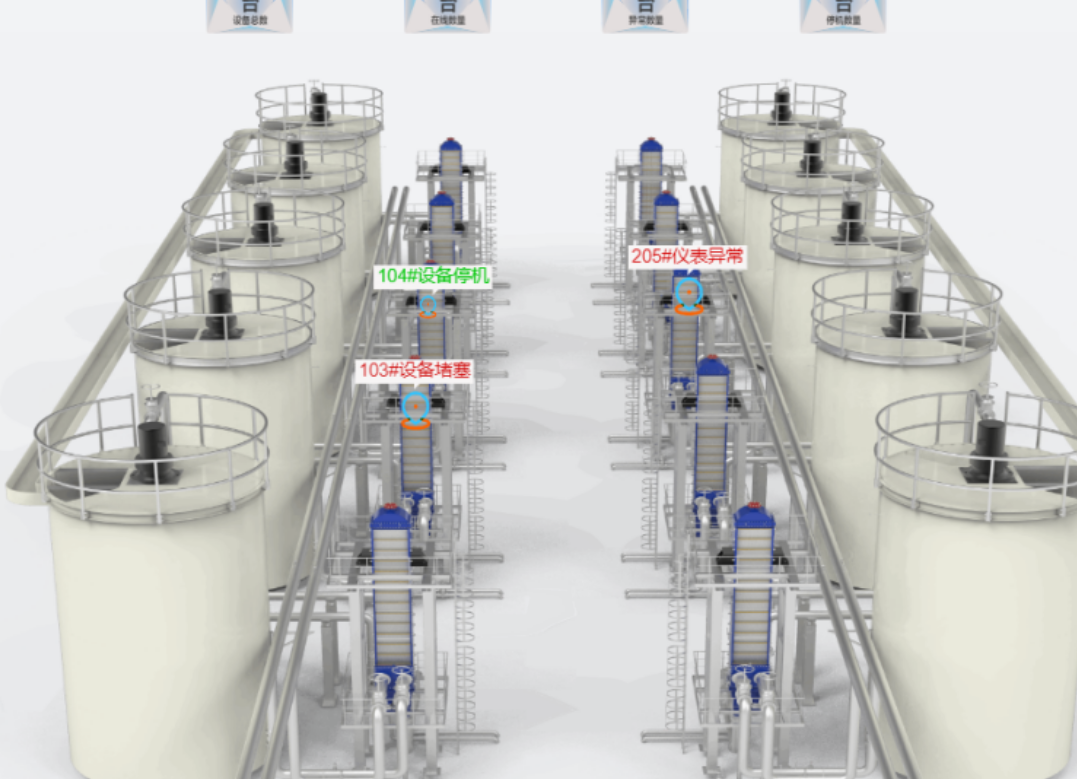

Pamusoro pezvo, sisitimu yekutarisa yakangwara ye "Smart Eye ™" inogona kutariswa se "uropi hwedhijitari" hwemuchina, iyo inogona kutarisa zvinhu zvakakosha panguva chaiyo senge tembiricha nekuderera kwesimba. Kuburikidza nemaalgorithms akangwara, inogona kuwana yambiro yekutanga nekukurumidza uye kugadzirisa mashandiro esimba, ichichengetedza mamiriro ekushanda kwemuchina achidzorwa uye ichiperekedza kugadzirwa kwakachengeteka uye kushanda zvakanaka.

Tsananguro yenhanho nhanho yekuiswa kweFully Welded Plate Heat Exchangers

Kugadzirira Kwekutanga: Kuisa Hwaro Hwakasimba Hwekuisa

- Kuongorora Nzvimbo uye Kuronga: Usati waisa, ongororo yakazara yenzvimbo inofanira kuitwa kuti ive nechokwadi chekuti pane nzvimbo yakakwana yekuisa uye inosangana nezvinodiwa nehukuru hwemidziyo. Nzvimbo yacho inofanira kunge iine mhepo yakanaka, iri kure nenzvimbo dzine tembiricha yepamusoro, hunyoro, uye gasi rinoparadza, uye kudzivirira kukanganiswa kubva kunzvimbo dzinodengenyeka. Panguva imwe chete, ronga nzvimbo yekushandira uye nzvimbo yekuchengetedza yakakomberedza michina kuti zvive nyore kugadzirisa nekugadzirisa gare gare.

Kuongorora Midziyo uye Kuunganidza Zvinhu: Kana michina yasvika, nyatsoongorora runyorwa rwezvinhu zvinoiswa mumidziyo kuti uve nechokwadi chekuti zvese zviri mumidziyo zvakwana uye hapana kukuvara kana kuchinja kwechitarisiko. Tarisa pakutarisa kunaka kwewelding yemaplates, uye tarisa kana welds dzakafanana uye dzichienderera mberi, uye kana paine zvikanganiso zvakaita semaburi nemaburi. Kana paine zvisina kunaka, taura nemutengesi nenguva kuti ugadzirise nazvo kuti uve nechokwadi chekuti mhando yemidziyo inosangana nezvinodiwa.

Kugadzirira Chishandiso NezvinhuGadzirira marudzi ese ezvishandiso zvinodiwa pakuisa, zvakaita semawrenji, midziyo yekukwidza, uye mazinga. Panguva imwe chete, zvichienderana nezvinodiwa pakuisa, gadzira zvinhu zvekuwedzera zvakaita sesealant nemagaskets kuti uve nechokwadi chekuti mhando yezvinhu inosangana nezvinodiwa pakushanda kwemidziyo.

Kuisa Midziyo Uye Kuisa Nheyo

Nzvimbo Yakarurama: Sarudza nzvimbo chaiyo yekuisa michina panzvimbo yekuisa zvichienderana nedhirowa rekugadzira uye mafambiro ekushanda kwayo. Shandisa maturusi akadai sedanho kuti uve nechokwadi chekuti kukanganisa kwenzvimbo yekuisa michina kuri mukati mehuwandu hwakatarwa kudzivirira kuyerera kwemvura kusina kuenzana kunokonzerwa nekutsvedza kwekuisa, izvo zvinokanganisa mhedzisiro yekuchinjana kwekupisa.

Kuvaka Nheyo: Nheyo yemidziyo inofanira kunge yakasimba uye yakagadzikana zvakakwana kuti ikwanise kutsungirira huremu nekudedera kwemidziyo panguva yekushanda. Pamusoro penheyo inofanira kunge yakati sandara uye yakatsetseka. Paunenge uchiisa mabhoti eanchor kana kuisa hwaro, nyatso dzora nzvimbo yavo nekukwirira kuti uve nechokwadi chekuti maburi ekuisa michina anoenderana nemaburi ekuisa. Mushure mekunge hwaro hwapera, ita kuomesa, uye michina inogona kuiswa chete mushure mekunge simba rasvika pazvinodiwa.

Kukwidziridza uye Kuisa Midziyo

Kuumbwa kweChirongwa Chekusimudza: Zvichienderana nehuremu, saizi yemidziyo, uye mamiriro enzvimbo yekuisa, gadzira hurongwa hwesainzi uye hwakakodzera hwekusimudza. Sarudza michina yekusimudza yakakodzera uye maturusi ekusimudza kuti uve nechokwadi chekuchengetedzwa uye kuvimbika kwemaitiro ekusimudza. Panguva yekusimudza, dzivisa kurovera nekubuda kwemidziyo, uye chengetedza pamusoro nezvikamu zvekushongedza zvemidziyo.

Nzvimbo Yakatsetseka: Munguva yekusimudza nekumisa michina, gadzirisa zvishoma nezvishoma nzvimbo yemidziyo kuti iwire nemazvo pamabhaudhi echigadziko kana pasi. Shandisa level kuti uone kuenzana kwemidziyo zvakare. Kana paine kutsauka, gadzirisa zvinyoro nyoro nekugadzirisa magasket nedzimwe nzira kuti uve nechokwadi chekuti michina yakaiswa yakatwasuka uye yakasimba.

Kubatanidza Mapaipi uye Kurapa Kuvhara

Kuiswa kweMapaipi: Isa mapaipi zvichienderana nezvinodiwa zvekugadzira kuti uve nechokwadi chekuti nzira dzemapaipi dzakakodzera uye marongerwo acho akanaka. Pakubatanidza mapaipi kumidziyo, dzivisa kumanikidzwa kurongeka kudzivirira kushushikana kwepaipi kuti isapfuudzirwe kumidziyo, zvichikanganisa kushanda kwakachengeteka kwemidziyo. Kune mapaipi anodziya zvakanyanya uye ane kumanikidzwa kwakanyanya, michina yekuripa inofanirwa kugadzirwa kuti itore kutama kunokonzerwa nekuwedzera kwekupisa uye kudzikira kwemapaipi.

Kurapa Kwekuvhara: Kuvhara kubatana pakati pepombi nemidziyo kwakakosha zvikuru. Shandisa sealant kana magasket emhando yepamusoro uye uzviise zvichienderana nemaitiro akatarwa ekuvhara. Sealant inofanira kuiswa zvakaenzana uye nehuwandu hwakakodzera, uye magasket anofanira kuiswa akati sandara uye asina makwinya. Simbisa mabhaudhi ekubatanidza zvakaenzana kuti uve nechokwadi chekuti kuvhara kunoshanda uye kudzivirira kubuda kwemvura pakati nepakati.

Kuisa Magetsi Nemidziyo

Kubatanidza Magetsi: Zvichienderana nemifananidzo yemagetsi yemidziyo, batanidza tambo dzemagetsi, tambo dzekudzora, nedzimwe tambo dzemagetsi. Iva nechokwadi chekuti kubatana kwemagetsi kwakasimba uye waya dzacho dzakarurama, uye kuiswa kwetambo dzemagetsi kunoenderana nezvinodiwa. Mushure mekunge kuiswa kwapera, gadzirisa system yemagetsi kuti uone kana mashandiro emagetsi emidziyo yacho akajairika.

Kuisa Zvishandiso: Isa zvishandiso zvekutarisa zvakaita sekupisa, kumanikidzwa, uye mwero wekuyerera kwemvura kuti uve nechokwadi chekuti nzvimbo dzekuisa zvishandiso dzacho dzakanaka uye dziri nyore kuona nekugadzirisa. Kubatana kwemidziyo kunofanira kunge kwakarurama uye kusina zvikanganiso, uye kutumira kwechiratidzo kunofanira kunge kwakagadzikana. Mushure mekunge kuiswa kwapera, gadzirisa uye gadzirisa zvishandiso kuti uve nechokwadi chekuti data rekuyera rakarurama uye rakavimbika.

Kugadzirisa Matambudziko eSisitimu uye Kugamuchirwa

Kugadzirisa Matambudziko nemuchina mumwe chete: Mushure mekunge michina yapera kuiswa, gadzirisa dambudziko nemuchina mumwe chete. Tanga michina uye tarisa kana michina ichishanda zvakanaka uye kana paine ruzha rusina kujairika kana kudedera. Tarisa ma parameter ekushanda kwemidziyo, akadai sekupisa, kumanikidzwa, uye mwero wekuyerera, kuti uve nechokwadi chekuti ma parameter ese anosangana nezvinodiwa zvekugadzira. Kana paine zvisina kunaka, misa muchina nenguva kuti ugadzirise zvikanganiso kusvika michina yashanda zvakanaka.

Kugadzirisa Matambudziko Pamwe Chete: Zvichibva pakugadzirisa mashandisirwo emuchina mumwe chete, ita kugadzirisa mashandisirwo emuchina pamwe chete. Tevedzera mamiriro chaiwo ekushanda kwekugadzira uye mhanyisa sisitimu yese kuti utarise mamiriro ekushanda pamwe chete pakati pemidziyo nemimwe michina yesisitimu. Tarisa kugadzikana kwekushanda kwesisitimu uye ona kana kushanda kwekupisa kuchisvika padanho rekugadzira. Gadzirisa matambudziko akawanikwa panguva yekugadzirisa mashandisirwo emuchina nenguva kuti uve nechokwadi chekuti sisitimu inoshanda zvakanaka.

Kugamuchirwa uye Kutumirwa: Kana kugadzirisa kwapera, ronga vashandi vakakodzera kuti vagamuchire michina. Ita ongororo yakakwana uye ongororo yemhando yekuisa michina, mashandiro ayo, dziviriro yekuchengetedzwa, nezvimwe zvinhu zvinoenderana nezvinodiwa. Kana kugamuchirwa kwabvumidzwa, saina magwaro ekugamuchirwa, uye michina yacho yaunzwa zviri pamutemo kuti ishandiswe.

Nzvimbo dzeKushanda neKugadzirisa Mushure meKuisa

Dzora Zvakasimba Mamiriro Ekushanda

Kutarisira Tembiricha: Panguva yekushanda, zvinorambidzwa zvachose kuti tembiricha yemuchina ipfuure muganho wepamusoro wedhizaini kudzivirira kuneta kwekupisa kwewelds kunokonzerwa nekupisa kwakanyanya. Tarisa shanduko yetembiricha yemuchina munguva chaiyo, isa alarm yekupisa inonzwisisika, uye tora matanho ekutonhodza panguva iyo tembiricha isiri yemazuva ese.

Kudzora Kumanikidzwa: Iva nechokwadi chekuti kumanikidzwa kwemuchina kuri mukati mehuwandu hwakatarwa kudzivirira kukundikana kwewelds nekuda kwekumanikidzwa kwakanyanya. Isa mudziyo wekutarisa kumanikidzwa kuti utarise kumanikidzwa panguva chaiyo. Kana kumanikidzwa kuchichinja-chinja zvisingawanzoitiki, tsvaga chikonzero nekukurumidza uye gadzirisa.

Kudzora Kusiyana Kwekupisa: Deredza musiyano wekupisa pakati pekupisa nekupisa kudzivirira kuneta kweplate welds kunokonzerwa nekushushikana kwakanyanya kwekupisa. Munguva yekutanga uye yekudzima michina, dzora zvine mwero mwero wekuyerera uye mwero wekuchinja kwekupisa kwekupisa nekupisa kuti uwane shanduko yakatsetseka.

Simbisa Kutarisirwa kweFluid Media

Kudzora Michina Inoparadza: Pazvinhu zvinopisa, gara uchitarisa pH yavo kuti uve nechokwadi chekuti hunhu hwezvinhu zvinopisa hunoenderana nezvinhu zvinonamira zvemuchina. Semuenzaniso, mumamiriro ekushanda ane chlorine yakawanda, sarudza michina yakagadzirwa nezvinhu zveC - 276. Zvichienderana nekuora kwechinhu chinopisa, gadzira matanho akakodzera ekudzivirira ngura kuti uwedzere hupenyu hwemuchina.

Kurapa Kusachena Kwezvikamu: Pakubata michina ine tsvina yakawanda, firita inofanira kuiswa, uye kunyatsoita kwayo kunofanira kuzadzisa zvinodiwa pakushanda kwemidziyo. Panguva imwe chete, zvichienderana nehunhu hwemidziyo, sarudza michina ine chiteshi chakafara kuti uderedze njodzi yekuvharika. Chenesa firita nguva nenguva kudzivirira kushanda kwemidziyo kwakajairika nekuda kwekuvharika kwefirita.

Magadzirirwo Ekuchenesa: Zvinorambidzwa zvachose kushandisa zvinhu zvekuchenesa zvine chloric acid kuchenesa michina. Kuchenesa zvisina kunaka kuchaita kuti welds dzibude uye dziboore. Gadzira hurongwa hwesainzi hwekuchenesa, uye sarudza nzira dzakakodzera dzekuisa pickling, alkali washing, kana physical flushing zvichienderana nehunhu hwemidziyo uye mamiriro ekushanda kwemidziyo. Kuchenesa kunokurudzirwa kuti kuitwe kamwe chete pagore kana mwedzi yega yega yekushanda kwe6 - 12. Mushure mekuchenesa, kurumidza kuona kumanikidzwa, kuyerera kwemvura, uye kushanda zvakanaka kwekuchinjana kwekupisa kwemidziyo kuti uve nechokwadi chekuti mashandiro emidziyo anodzokera kune zvakajairika.

Sanganisa Kushanda Nekuchengetedza Kwakangwara Nekuchengetedza Kwezuva Nezuva

Batidza Sisitimu Yekutarisa Yakangwara: Ita basa rakazara re "Smart Eye"™"Sisitimu yekutarisa yakangwara kuti iwane kutarisa kwemamiriro ekunze panguva chaiyo uye yambiro yekutanga yematanho akadai sekupisa, kuderera kwesimba, uye kushanda zvakanaka kwemidziyo. Kuburikidza nekuongorora data resisitimu, tsvaga nekukurumidza zvikanganiso zvinogona kuitika uye matambudziko ekudzikira kwekushanda kwemidziyo, tsvaga nekukurumidza nzvimbo dzekukanganisa, uye kupa gwara riri kure rekugadzirisa kuti uvandudze kushanda nekugadzirisa kwemidziyo.

Kuongorora uye Kugadzirisa Zuva Nezuva: Gadzira hurongwa hwekuongorora michina zuva nezuva, uye gara uchitarisa mamiriro ekushanda kwemidziyo, kusanganisira chitarisiko chemidziyo, zvikamu zvekubatanidza, uye kuverenga kwemidziyo. Tarisa kana paine mamiriro asina kujairika akadai sekubuda kwemvura, ruzha rusina kujairika, uye kudedera kwemidziyo, uye gadzirisa matambudziko anowanikwa nenguva. Gara uchichenesa uye uchichengetedza michina kuti pamusoro pemidziyo pagare pakachena uye kudzivirira kuungana kweguruva netsvina kuti zvisakanganise kupisa uye mashandiro emidziyo.

Matanho Ehunyanzvi Ekudzivirira Kukundikana Kwekutsvedza

Kudzora Kuchinja-chinja Kwekupisa: Dzivisa kuchinja-chinja kwakanyanya kwekushisa kwemidziyo kuti uderedze kuneta kwekupisa kwenzvimbo yekunamira. Gadzirisa maitiro ekugadzira, ronga zvine musoro nguva yekutanga nekudzima kwemidziyo, uye deredza kukanganiswa kwekuchinja kwekushisa pamichina yekunamira.

Kuve nechokwadi chemhando yepamusoro yekuwedera:Sarudza maitiro ekuwelda ane hunyanzvi uye uvake zvinoenderana nezvinodiwa pakuwelda. Ita bvunzo dzisingaparadze (senge kuona zvikanganiso zveX-ray) pazvikamu zvekuwelda kuti uve nechokwadi chekuti hunhu hwekuwelda hunoenderana nezvinodiwa. Kana paine mvura inoparadza, sarudza waya dzekuwelda nezvinhu zvinoenderana kuti udzivise kutsemuka kwengura.

Kurerukirwa Kushushikana: Panguva yekuisa michina nekubatanidza mapaipi, tora matanho ekusunungura kushushikana kwemidziyo nemapaipi kudzivirira kukuvara kwewelds kunokonzerwa nekuwanda kwekushushikana. Semuenzaniso, gadzira zvinotsigira mapaipi, zvinotsiva, nezvimwewo kuti utore kushushikana kunokonzerwa nekuwedzera kwekupisa uye kudzikira kwemapaipi.

Gadzira Maitiro Ekuwedzera Hupenyu hweMidziyo

Kutarisira Zvikamu Zvekuchengetedza: Gadzira hurongwa hwezvishandiso zvekuchengetedza zvinhu zvisina basa, uye gadzira ma spare plate bundles kana ma modules zvichienderana nemamiriro ekushanda kwemidziyo uye kutenderera kwekutsiva zvikamu zvisina kusimba. Iva nechokwadi chekuti kana michina ikakundikana, zvikamu zvekuchengetedza zvinhu zvinogona kutsiviwa nenguva, zvichideredza nguva yekumirira yekushanda uye kuve nechokwadi chekuti kugadzirwa kunoramba kuripo.

Kuronga Kugadzirisa: Rongai nesainzi nguva yekugadzirisa michina. Zvinokurudzirwa kuti muite ongororo yakazara nguva dzose kamwe chete pagore, uye kune masisitimu ane mabasa akakura, ongororo inofanira kuitwa mwedzi mitanhatu yega yega. Gadzirai hurongwa hwakadzama hwekugadzirisa, itai ongororo yakazara, kugadzirisa, uye kugadzirisa michina, uye nekukurumidza muwane nekugadzirisa matambudziko anogona kuitika kuti muwedzere hupenyu hwekushanda kwemidziyo.

Kutarisirwa kweMashandiro Ekugadzirisa:Simbisa kudzidziswa kwevashandisi kuti vagone kuziva nzira dzekugadzirisa kumanikidzwa nekupisa kwemidziyo uye kugona kutonga data risingawanzoitiki. Gadzira maitiro akaomarara ekushanda kwemidziyo, enzanisa maitiro evashandisi, uye dzivirira kukuvara kwemidziyo kunokonzerwa nekushanda zvisina kunaka.

Kugadzirisa Zvakatipoteredza:Simbisai manejimendi yenzvimbo yekuisa michina, torai matanho ekuderedza kukanganiswa kwezvinhu zvinodedera pamidziyo, uye iva nechokwadi chekuti michina yakaiswa zvakasimba. Itai basa rakanaka mumatanho anodzivirira hunyoro uye ekudzivirira ngura, chengetedzai michina kubva kuzvinhu zvakatipoteredza, uye gadzirai mamiriro akanaka ekushanda kwemidziyo.

Mhedziso

Semichina mikuru yekufambisa kupisa zvinobudirira mumunda wemaindasitiri, mhando yekuisa uye mashandiro uye kugadziriswa kwezvishandiso zvekupisa zveplate zvakasungirirwa zvakakwana zvine chekuita nekushanda kwemidziyo uye kushanda zvakanaka kwemakambani. Nekutevera gwara resainzi uye rakaoma rekuisa nhanho nhanho uye nzvimbo dzekushanda nekungwarira, kushanda kwakasimba uye kwakanaka kwezvishandiso zvekupisa zveplate zvakasungirirwa zvakakwana mumamiriro ekushanda akaoma akadai sekupisa kwakanyanya, kumanikidzwa kwakanyanya, ngura iri nyore, uye kuvharika kuri nyore kunogona kuve nechokwadi, zvichibatsira mabhizinesi kuzadzisa chinangwa che "kushanda kwakachengeteka + kuderedza mari uye kuvandudza kushanda zvakanaka".

Shanghai Heat Transfer Equipment Co., Ltd., semupi anotungamira wemhinduro dzekupisa muindasitiri, ine ruzivo rwakakura uye timu yehunyanzvi, inogona kukupa mhinduro dzakagadzirirwa dzezvishandiso zvekupisa zveplate zvakasungirirwa zvakakwana uye rutsigiro rwakakwana rwehunyanzvi. Ingave kusarudzwa kwemidziyo, nhungamiro yekuisa, mashandiro nekugadzirisa, kana kugadzirisa zvikanganiso, tichakushandira nemoyo wese. Kana uchida rumwe ruzivo kana rubatsiro, ndapota inzwa wakasununguka kutibata nesu.:

Tsamba yemagetsi:

zhanglimei@shphe.com

qiuying@shphe.com

WhatsApp / Nharembozha:+86 15201818405

WhatsApp / Nharembozha: +86 13671925024

Nguva yekutumira: Kurume-25-2025