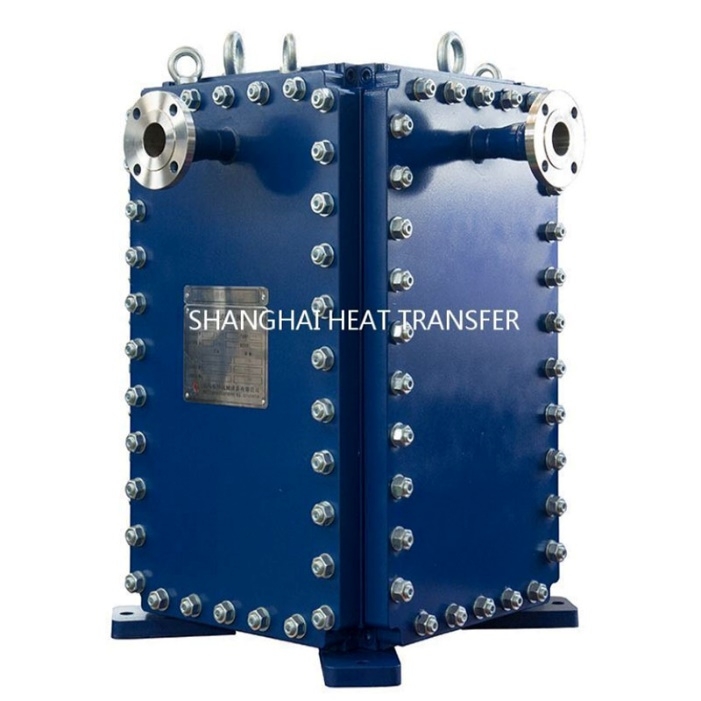

The HT-BLOC welded plate heat exchanger, produced by Shanghai Heat Transfer Equipment Co., Ltd.(SHPHE) represents a significant advancement in the field of welded plate heat exchangers. This type of heat exchanger is known for its compact, efficient, and durable design, making it an excellent choice for handling aggressive and high-temperature fluids where gasketed plate heat exchangers cannot be used.

Key Features of HT-BLOC welded plate heat exchanger

High Efficiency: HT-BLOC welded plate heat exchanger is designed to maximize heat transfer by optimizing the surface area of the plates, which allows for efficient heat exchange even in applications involving high temperatures and pressures.

Compact Design: Its compact structure makes it an ideal solution for applications with space constraints. Despite its small size, it offers high thermal efficiency and capacity.

Durability and Reliability: Made from durable materials, typically stainless steel or titanium, BLOC heat exchangers are built to withstand corrosive materials, high temperatures, and pressures, ensuring long-term reliability.

Ease of Maintenance: While HT-BLOC welded plate heat exchangers are welded and gaskets free, their design still allows for relatively easy access for cleaning and maintenance compared to traditional shell and tube heat exchangers.

Versatility: They can be used in a variety of industries, including oil and gas, petrochemical, and food and beverage, for tasks such as cooling, heating, condensing, and evaporating.

Applications

HT-BLOC welded plate heat exchangers are suited for a wide range of applications, particularly where the use of gaskets is not advisable due to the aggressive nature of the fluids or when operating temperatures and pressures are beyond the limits of gasketed heat exchangers. Some common applications include:

Chemical Processing: Handling aggressive chemicals that require robust materials to avoid corrosion and leakage.

Oil and Gas: Used in the processing of crude oil and natural gas where high temperatures and pressures are common.

Power Generation: For cooling or heating in power plants, especially in closed-loop systems where minimal fluid loss is critical.

Heavy Industry: In metallurgy and mining processes where the fluids may contain particulates or be highly corrosive.

Choosing a HT-BLOC welded plate heat exchanger

Selecting the right HT-BLOC welded plate heat exchanger involves considering several factors, including the nature of the fluids to be processed, the required heat transfer rate, operating pressures and temperatures, and the available space for installation. It is crucial to consult with the manufacturer to ensure the selected model meets all operational requirements and to take advantage of their expertise in optimizing the heat exchanger configuration for specific applications.

In summary, HT-BLOC welded plate heat exchanger by SHPHE offers a combination of efficiency, durability, and versatility, making it a preferred choice for challenging industrial applications. Its design and construction make it capable of handling the demands of various sectors, providing a reliable solution for heat exchange needs.

Post time: Feb-23-2024