Kev Taw Qhia

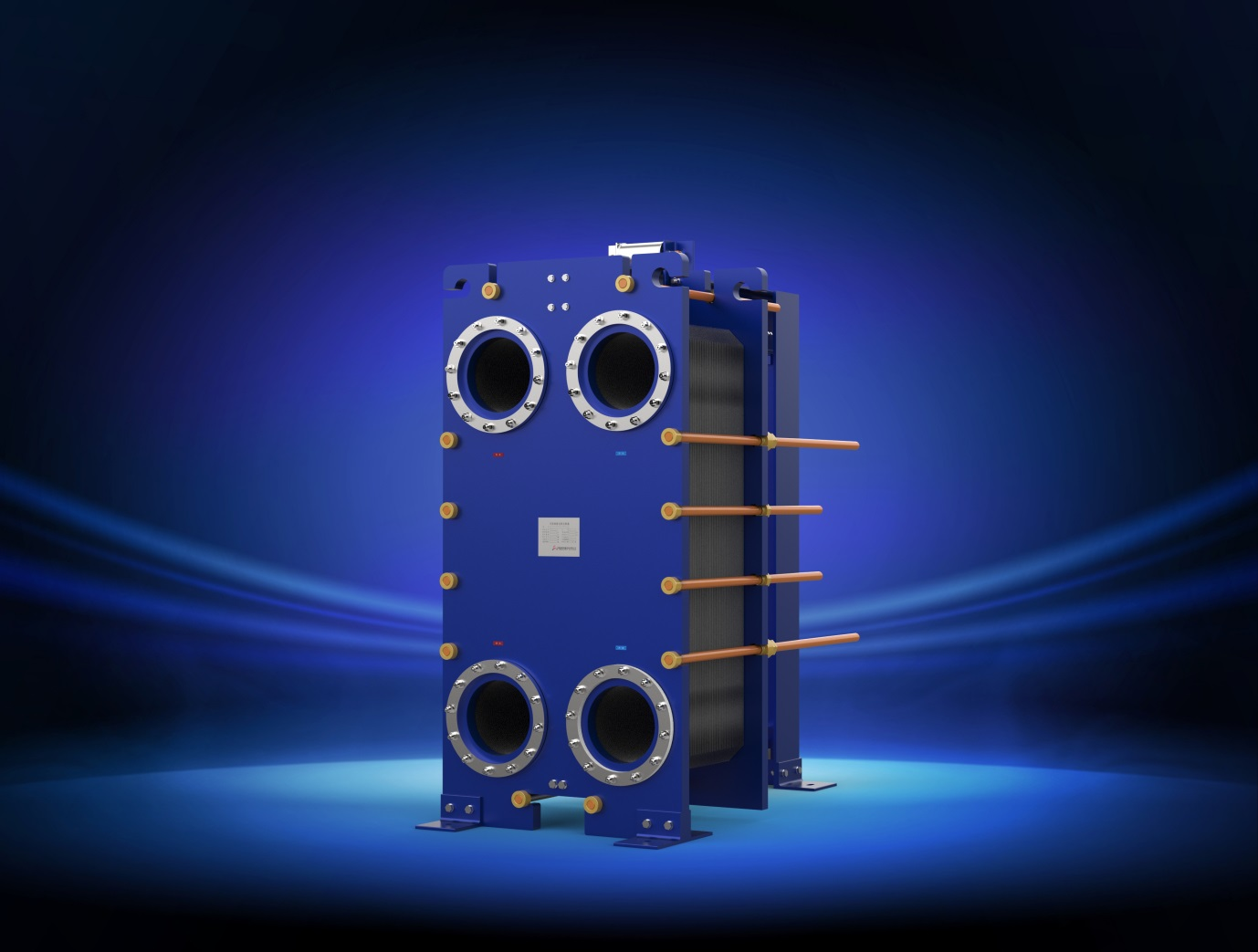

Koj puas paub tias kev tsis quav ntsej txog kev saib xyuas koj li niaj zausgasket phaj kub exchangerpuas ua rau nws qhov kev hloov pauv cua sov poob qis txog li 30%? Qhov kev poob qis no cuam tshuam rau kev siv hluav taws xob thiab cov nqi ua haujlwm. Thaum cov lag luam nrhiav kev ua haujlwm zoo thiab ruaj khov, kev tswj hwm kev ua haujlwm zoo tshaj plaws ntawm cov khoom siv hloov pauv cua sov tsis yog qhov xaiv tau lawm - nws yog qhov tseem ceeb.

Cov khoom siv hloov pauv cua sov ntawm cov phaj gasket siv dav hauv cov lag luam xws li kev ua zaub mov, tshuaj lom neeg zoo, kev tsim tshuaj, thiab HVAC systems. Txawm li cas los xij, cov kwj dej nqaim ntawm cov phaj feem ntau yuav ua rau muaj kev puas tsuaj, tsim cov biofilm, thiab cov khoom me me, ua rau muaj kev tiv taus cua sov ntau ntxiv, kev poob siab tsis zoo, thiab cov khoom siv tsis ua haujlwm.

Phau ntawv qhia no muab cov txheej txheem ntxuav kom huv si, ib kauj ruam zuj zus, uas suav nrog kev npaj, kev rhuav tshem, kev ntxuav, kev sib dhos dua thiab kev sim, thiab cov tswv yim txij nkawm tiv thaiv, pab koj tsim kom muaj ib lub kaw lus tswj kev txij nkawm tshaj lij.

1. Kev Npaj: Cov Cuab Yeej Tseem Ceeb thiab Kev Ntsuas Kev Nyab Xeeb

Torque wrench: Xyuas kom lub bolt nruj sib npaug thaum lub sijhawm rov sib dhos kom tiv thaiv kev xau lossis phaj deformation.

Cov txhuam mos thiab cov ntaub mos uas tsis txhuam: Siv rau kev tshem tawm cov av qias yam tsis khawb lub phaj nto.

Lub tshuab dej siab siab: Pab ntxuav cov phaj kom huv si thiab tshem tawm cov tshuaj seem.

Cov khoom siv tiv thaiv tus kheej: Hnav cov hnab looj tes thiab cov tsom iav thoob plaws hauv cov txheej txheem kom tsis txhob raug mob los ntawm tshuaj lom neeg lossis cov pa phem.

Kev Ua Pa: Xyuas kom muaj cua ncig zoo, tshwj xeeb tshaj yog thaum siv cov tshuaj ntxuav acidic.

Kev rho tawm hluav taws xob: Tshem tawm cov khoom siv hluav taws xob thiab hydraulic/pneumatic ua ntej pib ua haujlwm.

Ua ntej ntxuav, xyuas seb puas muaj xeb, gasket puas laus, lossis puas puas rau lub thav duab. Hloov cov khoom puas ua ntej txuas ntxiv mus.

2. Kev rhuav tshem ntawm Lub Tshuab Hloov Kub

Maj mam li xoob cov bolts hauv ib kab pheeb ces kaum kom tsis txhob muaj phaj warping.

Ua tib zoo tshem cov phaj tawm, khaws cia qhov kev txiav txim qub kom tiv thaiv kev ua yuam kev ntawm txoj kev ntws.

Sau daim ntawv lo thiab sau cov qhov chaw ntawm lub phaj thiab gasket kom rov sib dhos tau zoo.

Muab cov phaj tso rau ntawm ib qho chaw mos kom tsis txhob khawb lossis sib tsoo.

Ua tib zoo tuav cov gaskets, tsis txhob raug rau qhov kub thiab txias lossis cov tshuaj lom neeg hnyav.

3. Cov Phaj Ntxuav thiab Cov Gaskets

Siv cov kua qaub qaug zog uas diluted xws li citric acid los yog phosphoric acid los yaj cov nplai thiab cov organic deposits.

Kev ntub dej thawj zaug: 30–90 feeb nyob ntawm seb muaj kuab paug ntau npaum li cas.

Tsis txhob siv cov kua qaub muaj zog xws li nitric lossis hydrochloric acid kom tiv thaiv kev xeb intergranular.

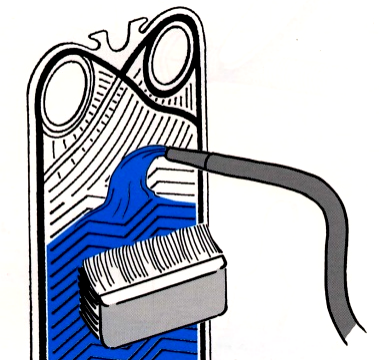

Siv cov txhuam hniav mos mos los yog cov cuab yeej ntxuav tshwj xeeb los ntxuav.

Yog tias muaj av qias ntau, xav txog kev siv cov txhuam txhuam tig lossis kev co maj mam, tswj qhov hnyav ntawm kev ntxuav.

Yaug kom huv si nrog dej huv los yog dej deionized siv lub tshuab cua siab.

Tshawb xyuas txhua lub phaj kom zoo zoo rau qhov pinholes, tawg, lossis deformation.

Xyuas qhov resilience thiab adhesion ntawm lub gasket; hloov yog tias tsim nyog.

4. Rov sib dhos thiab sim

Rov muab cov phaj ntsaws rov qab raws li qhov chaw sau tseg thiab kev taw qhia ntws.

Xyuas kom cov gaskets haum zoo yam tsis muaj buckling, txav mus los, lossis sib tshooj.

Maj mam li zawm cov bolts hauv cov qauv crisscross siv lub torque wrench.

Ua raws li cov lus qhia ntawm lub tshuab ua kom lub zog nruj kom tsis txhob nruj dhau lossis hloov pauv.

Kev Ntsuas:

Ua qhov kev sim dej qis thawj zaug kom paub seb puas muaj qhov xau.

Yog tias tsis pom muaj qhov xau, maj mam nce qhov siab mus rau qib ua haujlwm tsim.

Sau hnub tim ntxuav, cov tshuaj siv, cov concentration, thiab txhua yam teeb meem uas tau txheeb xyuas.

Khaws cov duab thiab cov ntaub ntawv xeem rau kev taug qab kev saib xyuas.

5. Cov Lus Qhia Txog Kev Txij Nkawm Tiv Thaiv

Kho kom raug lub sijhawm ntxuav raws li lub sijhawm ua haujlwm, hom xov xwm, thiab tej yam ib puag ncig (feem ntau txhua 6-12 lub hlis).

Txo cov sijhawm ua haujlwm hauv qab cov xwm txheej hnyav xws li kev tuav cov khoom khov, dej tawv heev, lossis cov khoom siv viscous.

Nruab cov sensors rau qhov kub thiab txias, qhov siab poob, thiab qhov nrawm ntws, uas koom ua ke nrog cov kab ke.

Teem cov tswb ceeb toom tsis siv neeg rau qhov ua haujlwm poob qis lossis qhov siab poob qis tsis zoo.

Ua kev cob qhia tsis tu ncua uas muaj kev ua haujlwm tiag tiag thiab kev xav, txhim kho kev muaj peev xwm kuaj mob.

Xaus lus

Ua ib lub cuab yeej hloov cua sov tseem ceeb, qhov xwm txheej ua haujlwm ntawm lub phaj hloov cua sov cuam tshuam ncaj qha rau kev ruaj khov thiab kev siv hluav taws xob ntawm tag nrho cov txheej txheem. Ib txoj cai ntxuav uas muaj qauv thiab ua raws li tus qauv tsis yog tsuas yog ua kom muaj kev hloov cua sov zoo dua xwb tab sis kuj ua rau lub neej ntawm cov khoom siv ntev dua thiab txo cov nqi ua tsis tiav.

Kev tsim kom muaj kev saib xyuas zoo—kev sib xyaw ua ke ntawm kev saib xyuas sensor, kev pabcuam tshaj lij, thiab kev cob qhia sab hauv—yuav ua rau koj cov cuab yeej hloov pauv cua sov muaj nqis mus ntev.

Yog xav tau kev pab tu vaj tse, kev pab xaiv khoom, lossis kev daws teeb meem txij nkawm, thov hu rau peb.us:

Email:

zhanglimei@shphe.com

qiuying@shphe.com

WhatsApp / Xov Tooj:+86 15201818405

WhatsApp / Xov Tooj Ntawm Tes: +86 13671925024

Lub sijhawm tshaj tawm: Plaub Hlis-15-2025