Are you feeling overwhelmed by the various options when it comes to choosing a plate heat exchanger? Let our company guide you through the crucial factors to consider for the right selection.

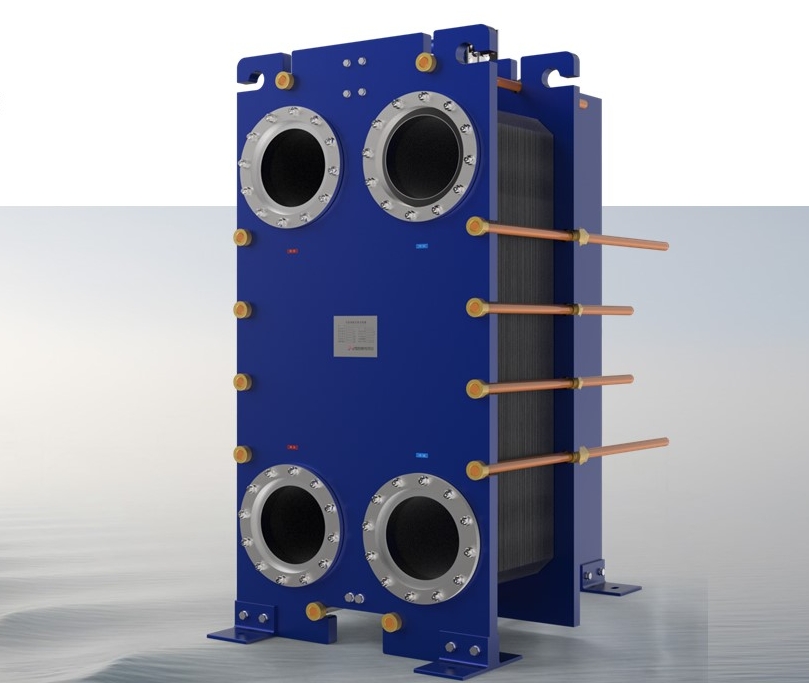

1、Choosing the Right Model and Specification: Plate heat exchangers come in a wide range of models and specifications, and the decision should be based on specific operating conditions and applications. We take the time to understand your heat transfer requirements and engage in industry discussions. For example, in cases where high flow rates and low-pressure drops are essential, we recommend models with lower frictional resistance. Conversely, for other scenarios, we suggest different options. When selecting stainless steel all-welded plate heat exchangers, we meticulously measure key parameters to ensure the most suitable model for long-term stable performance.

2、Configuration of Flow Channels and Plates: Inside a plate heat exchanger, a group of parallel flow channels allows the fluid to flow in the same direction, with similar plate arrangements forming a secure path for fluid circulation. Our expertise in special processing and installation ensures diverse flow channel configurations to meet varying customer demands. Clients can calculate and select the best plate arrangement based on key parameters to achieve efficient cooling and heat transfer processes, while closely matching heat transfer coefficients within each flow channel for optimal thermal conductivity.

3、Pressure Drop Considerations: Pressure drop has a direct impact on plate heat exchanger performance and is taken into account in the selection process. We set specific regulations for this purpose. While selecting plate heat exchanger models, we carefully consider heat transfer and gas pressure to provide customized solutions that meet processing and safety requirements.

Post time: Jul-24-2023